The metal structures plant DELSNAB will produce screw metal stairs in Moscow quickly and efficiently. Our specialists have extensive experience in implementing projects for the production of spiral staircases. Having our own material and technical base in Moscow allows our company to install optimal prices for our products.

One of the main areas of work of our plant is the design, manufacture and installation of stairs and stair railings. You can order a spiral metal staircase directly from the manufacturer, and we are ready to begin right now both to carry out large projects from enterprises and developers, and to orders from individuals. We are located in Moscow, which is convenient for residents of Moscow and Moscow Region.

The table shows the types of stairs offered by Delsnab. Prices for spiral metal staircases are per 1 meter.

| Photo | Description | Price per m.p. |

|---|---|---|

|

The staircase is spiral, compact, with a platform.Consists of wedge-shaped simple steps that are attached narrow end on support column or pillar. There is a platform. |

|

|

Spiral staircase to the second floorHeight 1.5-2 m. Can have any slope and height of the steps of the structure. Compact. |

|

|

Metal spiral staircase, on a support stand.Individual steps are attached to a monolithic support column. Has a rotation angle of up to 360° |

|

|

Metal spiral staircase with railingMay have different sizes screw lifts. Between the steps the height is from 17 to 20 cm. |

|

|

Fire spiral staircaseMade from non-flammable alloys treated with an anti-corrosion compound. Anti-slip. |

Features of the structure of spiral staircases

A spiral staircase consists of a post to which the steps are attached directly. The stand is spiral-shaped, with treads attached to it. To ensure comfort when moving along a spiral staircase, and also in accordance with GOST, the tread width is 20-40 cm. A staircase of this type is fixed to the floor on the first floor and attached to the end of the ceiling on the second floor.

A distinctive feature of spiral staircases is that they do not require load-bearing wall. The structure can be installed anywhere, even in the middle of the room.

You can order a spiral metal staircase from us from the manufacturer of the following types:

Metal spiral staircases made from different types metal They are divided into 4 types:

Buy a metal spiral staircasepossible with various attachments of steps.

From us you can buy a spiral staircase made of metal in Moscow. Our metal spiral staircases have the best prices due to own production. We can guarantee the quality of the product and its reliability. To buy a spiral metal staircase to the second floor, you need to place an order in the feedback form on our website.

Such engineering solutions are not very popular in private buildings, as they are characterized by a number of disadvantages - the steepness of the climb, and this does not suit many; complexity of installation; impossibility of moving anything large from floor to floor. But the fact that spiral staircases are compact and can be installed anywhere is relatively small area- an indisputable fact.

In addition, their final price is significantly lower than models assembled according to other schemes due to reduced material consumption. It is these arguments that in some cases are decisive when choosing design. We will look in detail at how to make a metal spiral staircase with our own hands.

There is no point in considering the issue of assembling a spiral staircase from ready-made factory-made elements (although this is also done by hand). Each kit comes with instructions in which everything is explained point by point. But if you mount it from scratch, you first need to evaluate your own capabilities and decide on a number of points.

The casting technique, as well as the assembly of the structure using bolted connections, clearly not suitable. The first is due to the impossibility of implementation, not only at home, but also in a small, albeit specialized, workshop. The second will not ensure the reliability of the spiral staircase, taking into account the constant dynamic loads, to which all its components will be subjected daily. There remains only one acceptable option for performing all operations with your own hands -. If desired, practical skills can be acquired in a relatively short time.

Taking into account the fact that the installation is done with your own hands, by welding, best option– steel. It will provide the required reliability of the structure and, in addition, it is easy to process at home. The processes of coating metals with polymer layers and nickel plating are described in some detail on our website.

There are recommendations for the use of aluminum for the manufacture of railings. The arguments are light weight and the possibility of independently anodizing structural parts (handrails, balusters, opening filling elements). The author will not argue with this, but draws attention to the fact that we're talking about about the spiral staircase. Consequently, the requirements for the reliability of the fence (taking into account the steepness) increase sharply. That is why for such structures it is necessary to use only steel. And all other materials are only as additions, serving as decorative elements, nothing more.

Installation is carried out based on the features load-bearing structure spiral staircase.

Both ends are open, and the step itself is located on the supporting element (beam) of the spiral staircase.

On pain.

They are set out in detail in the relevant GOST and SNiP. It makes no sense to list them all, since most of them are needed only by professional designers. In addition, each document contains a number of references to other regulations concerning, for example, the characteristics of steels, requirements for welds etc. When making a spiral staircase with your own hands, given its short length, it is enough to know the basic principles.

There are many sites on the Internet that offer online calculators. But even if the calculations are done independently, the original data does not change. What will need to be determined?

Before starting calculations, it is necessary to convert all quantities into unified system. As a rule, calculations are usually done in mm, but in fact, it’s more convenient for everyone. The main thing is not to substitute values, for example, for height in m and radius in cm, into formulas.

The length of the march (L) is determined. In other words, this is the circumference (along the rise line). We remember that it is spaced from the wall by a third of the radius of the stairs. Therefore, r = 2/3 R. How to calculate it correctly?

The diameter of the spiral staircase is (the width of the step x 2) + the cross-section of the central support. Only after finding this value can we begin to determine the “small” radius, the value of which is substituted into the formula known from school:

L = 2π x r

The number of steps on the march is determined. Knowing the depth of the tread, this is easy to do:

N = L/h1

You can do it another way - divide H by h. The technique is selected based on a specific engineering solution. If the procedure for calculating the number of steps is clear, then everything else is not important.

One should not lose sight of such a parameter as the thickness of the steps. The total value is subtracted from the height of the stairs before calculating their number.

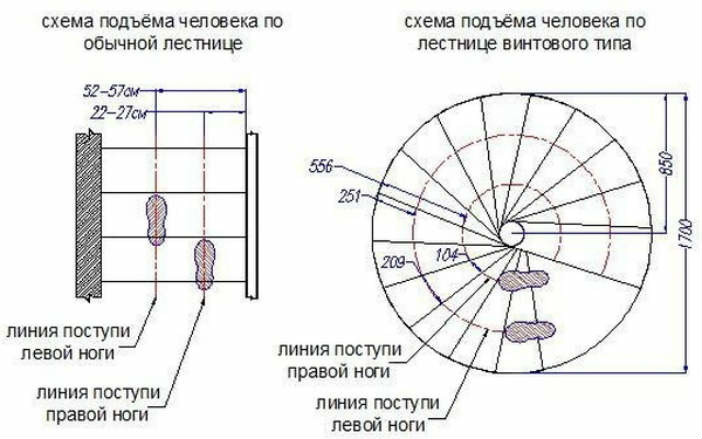

The diagrams and tables below will help the reader find answers to the questions that arise.

It remains to add that in most cases it is advisable to initial stage install the load-bearing part of the structure, and install all other elements in place.

Good luck to you in this matter!

Spiral staircases (metal) are a type of steel structure where the steps are arranged in a spiral pattern in a circular area. At the moment they are a very popular type of structure. The model combines elegance and compactness. It is used in the construction of almost any building, be it a dacha, a private house, a building with a second floor, or an entertainment center or office. They serve an excellent alternative wooden and other structures with wide flights of stairs. Wherever space-saving as well as effective performance is required decorative look, spiral-shaped structures consisting of a number of steps are installed.

Showing 1-18 of 32 results

Of course, like any other thing, steel structures have disadvantages. The main ones are:

A spiral staircase is a structure in which there are no inter-flight spans, and there is a central support pillar, serving as the basis for the steps. It represents a general cascade of steps.

Production steel stairs can be carried out from various materials(wood, ceramics, plastic, glass, stone and metal). Spiral-shaped metal structures are found the following types: welded, cast, prefabricated and forged. In terms of cost, the last two options will be more expensive.

According to the load-bearing element used steel structures can be installed as follows:

In our company you can buy or order a metal staircase (spiral) made of steel at an affordable price in Moscow. By contacting us, you can be sure that a custom-made spiral metal staircase will be completed as quickly and efficiently as possible.

Our specialists will take into account all your wishes and produce a design that meets your needs. It can be made in any style.

For your safety and convenience, the order is made and completed with railings and fences.

The price of metal spiral staircases to the second floor varies based on several parameters: material, type of construction, decorative components and dimensions.

Call our operators and they will be happy to help you choose suitable option in Moscow. Phone numbers are listed on the website. You can also write to us by email.

The online store operates permanent discounts and shares.

You can buy a cascade metal staircase with delivery throughout Moscow, as well as pickup. Delivery is carried out as soon as possible.

Buy reliable products by choosing our company!