Without good ventilation in the steam room, you won’t get real pleasure from the bath, and for people who cannot boast of good health, going to such a bath is completely dangerous. In this article, we tell you how to make ventilation in the bathhouse, and analyze the “classics without ventilation ducts”: how our ancestors ventilated the steam room and how it might look in a modern solution.

In a classic Russian bath, two ventilation schemes were commonly used:

Volley ventilation is carried out through an open door and window. We emphasize: we are talking about a wet steam bath, not a sauna.

Building for myself FORUMHOUSE member

I had to quarrel with the customer and insist that an opening for a window be cut in the 500 mm thick wall.

To obtain air to breathe in the steam room, a window next to the shelf and a door to the dressing room are enough. The window and the door must be opened between visits while we are resting. Then we return to the steam room, close the window and the door and steam again.

To dry the steam room, they make a small vent in it (there are different options: some make it in the far corner under the ceiling, others, on the contrary, under the shelf). After using the bath, open:

This creates a stream of air that ventilates the room and removes moisture from it.

In the photo: the bathhouse of our user with the nickname Vasisdas.

For a FORUMHOUSE user with the nickname Nomadic, the ventilation in the bathhouse is done as follows: air inflow is under the furnace firebox, the exit is diagonally under the ceiling. Usually everyone steams with a closed hood, but sometimes it is opened, “if the steamer is not extreme”, and in this case natural ventilation works.

When you want to freshen the air in the steam room after several visits, the hood opens, a shock dose of boiling water splashes into the heater.

Nomad

All the old steam is blown out the hood window. After that, I wave the doors a little, creating an additional flow, put a new wormwood, close the window, and the steam room is as good as new, as if it had never been steamed there.

There is also an interesting way of airing the bath, which came down from our ancestors, which EsKor, a member of our portal, saw in the bath “at one gray-haired grandfather”. In this bath, the only specially made means of ventilation was an outlet a meter from the floor, under the shelf. What is the meaning of such a breather? It turned out that the gray-haired grandfather “freshened” the air in the steam room in almost the same way as Nomad, only he prepared a bucket of ice water in advance and poured it on the shelves either a moment before or immediately after a shock dose of water was charged into the heater.

EsKor

Grandfather explained that the cold water that falls on the floor from the shelf pulls the steam down to itself, and it takes the stale air with it and flies into the vent. No mysticism, physics explains this matter well.

Cold water cools the steam, condensation occurs, a decrease in pressure causes an increased flow of air above the steam layer, and the steam literally falls from the ceiling.

It is clear that this method is not suitable for dry-air baths and for steam rooms with a blank floor and no drain.

Let's consider how such a ventilation system works on the examples of several saunas of FORUMHOUSE participants.

Here is the bathhouse of our participant with the nickname Vasisdas.

Vasisdas

Everything ingenious is simple! Heater stove, door, window and solid wood. Learning how to use it is a matter of technology.

How the window in the steam room was made: a double-glazed window on the side of the facade of the bath, a ventilation gap in the thickness of the wall pie, on the side of the steam room there is a decorative window. This avoids unnecessary heat loss and is simply beautiful.

Our member with the nickname I build for myself a small combined steam room-washing room, 2.5 by 2.1 and 2.1 m high.

The ventilation system includes:

The upper air is always closed, it is opened only to dry the steam room after use. Also, our user sometimes opens it to create a softer mode for his wife and daughter.

While vaping, all openings are closed. The height of the window is chosen successfully, the heat from the steam room is not blown out.

During soaring, two types of ventilation are used:

To dry the steam room, all openings and windows are opened.

I build for myself

The air from the street through the dressing room window goes along the floor into the lower vent under the shelf (draft), partially heated by the still hot stove and rises above the shelf into the upper vent. There is a draft under the floor from the vents in the basement. In winter, I close them for soaring.

Such "old ways" of bath ventilation, without arranging ventilation ducts, our user considers justified and quite sufficient for a heat-intensive stove.

This is how ventilation is arranged in the bathhouse of our participant with the nickname Mikhalych Titov. The inflow is made through a half-brick hole in the side wall.

When viewed from the street, it looks like this.

The downward branch, into which condensate flows, is closed with a screw plug. The entrance from the sink is made under the oven.

When building a bath, a member of our portal with the nickname Chagav attached special importance to ventilation. In the rest room, he made forced ventilation (one inlet and two exhaust), and natural ventilation was made in the steam room.

If desired, air enters the steam room from the street - pipes are poured into the foundation, corrugated stainless steel passes through the stones of the stove. It opens and closes with a latch.

Ventilation in the bath is not only comfort, but also an urgent need. It is needed both during and after bath procedures:

At the same time, bath ventilation is quite complex and diverse in design. Of course, the question can be reduced to financial investments, but in fact, you just need a good ventilation specialist who will find the best solution in each case. We will consider all the possibilities and features of the device.

Ventilation systems in baths are divided at once according to several parameters:

Let us explain that the forced one differs from the natural one by the presence of fans that forcibly drive air in or out, the local one differs from the general exchange one in its local character, for example, the chimney above the stove is local ventilation, and the vents are part of the general exchange.

Let us explain that the forced one differs from the natural one by the presence of fans that forcibly drive air in or out, the local one differs from the general exchange one in its local character, for example, the chimney above the stove is local ventilation, and the vents are part of the general exchange.

As for the supply, exhaust and their combination, these are indications of which air is directed where: the exhaust drives the exhaust air out, the supply air drives fresh air in, and their combination creates a balanced air exchange inside the room.

These are general terms for any ventilation, but our task is to consider a bathhouse that has its own specifics. We advise you to familiarize yourself with (8 types) along the way.

Watch a short video, as one of the options for organizing ventilation in the bath:

It works on the principles of physics, which say that heating makes air lighter and causes it to rise. And an increase in the volume of cold air accelerates the movement of hot air. Knowing about this property, you can not install any devices at all, there are enough ventilation holes, the location of which will make some of them supply air, and others - exhaust.

And in the bath there is a stove, and this is a very favorable circumstance for the direction of air circulation. If the natural ventilation inlet is located near the floor next to the blower, then the stove itself will draw in fresh air, without any fan. Also, raising the finished floor just above the hole under the firebox contributes to improving traction.

The exhaust opening is usually made on the side that is opposite the wall with the supply opening, but this is not the only option.

If fans are placed in the same holes, then you can not be afraid of calmness or other weather conditions that adversely affect the air circulation in the bath.

In principle, there is no big difference between natural and forced ventilation in the circuit itself, it is only a matter of which holes the fans are in. Because you can not put them everywhere, reinforcing only the exhaust or only the inflow. But by creating a large difference between the inflow and outflow, we change the pressure in the room. This is easily detected by the way the door slams. The task is to create a balance between outflow and inflow, and the air during bath procedures should circulate slowly, without causing a draft. And when drying, a draft is only good.

IMPORTANT! The direction in which the fan drives the air depends on the location of its blades, so it is important to ensure that there is no exhaust fan in the supply opening and vice versa.

Bath ventilation can be conditionally divided into permanently functioning (roofing, foundation, wall) and periodically functioning, during bathing procedures and stove operation. Both are parts of a single ventilation system, which is laid during construction.

The principle of operation of the ventilation system: displacement of exhaust air with fresh air. In the most primitive case, two holes are enough for this, but in practice, flow directions also matter, so the number of supply and exhaust holes can be increased, and they themselves are equipped with dampers, which are a means of controlling flows, their volumes and speed.

The principle of operation of the ventilation system: displacement of exhaust air with fresh air. In the most primitive case, two holes are enough for this, but in practice, flow directions also matter, so the number of supply and exhaust holes can be increased, and they themselves are equipped with dampers, which are a means of controlling flows, their volumes and speed.

Regardless of the location, the air inlets are always lower than the exhaust ones. Sometimes air flow is provided through the blinds at the bottom of the door to the steam room. But there is one rule: Where does the air come from, where should it go?. If we take from the premises, we need to return not to the street, but also to the premises. Otherwise it won't work.

The calculation of the area of ventilation windows is quite simple: we must proceed from the fact that each cubic meter of room volume needs a window with an area of 24 cm². Windows in no case are made directly opposite each other at the same height.

Also prepared to help you (10+ different schemes).

Bastu-type ventilation, named after convection Swedish baths, is gaining more and more popularity in Russian baths. It is easy to make and highly effective.

The air flow under the furnace is carried out using a ventilation pipe from the street. In this case, a damper is required that would block it.

For air outflow, a box is mounted, which starts 20-30 cm from the floor and goes outside. The location of the box is diagonally from the furnace. The material is best stainless steel. The box must also overlap 100%.

So, it works as follows: if a certain volume enters the room, then the corresponding volume will be pushed out from there if there is an exit. A working furnace actively sucks in cold air from the supply air duct. Part of it is used in combustion (and leaves through the chimney), and part rises, heating up along the way from the stove. The excess volume in parallel begins to leave through the box, which takes air from the floor. Therefore, fresh heated air is in the breathing zone, and the exhaust is at the bottom and leaves.

See how Bastu is explained and done in these videos:

Bastu ventilation is “turned on” and “turned off” by manipulating the valves. At the same time, the stove must work, because it is she who is the heat pump responsible for air circulation. If the stove goes out, the bastu ventilation in the bath will not work.

Bastu ventilation is ideally used in the sauna, where you need to change the air 6-8 times per hour. But in the Russian bath, the conditions are somewhat different, and although you can put the bass in it, there are restrictions on its use.

Russian banya is not too high temperature and plenty of steam. Under such conditions bastu ventilation in a Russian bath should not be “turned on” while soaring.

Russian banya is not too high temperature and plenty of steam. Under such conditions bastu ventilation in a Russian bath should not be “turned on” while soaring.

But you can safely start it at the very beginning, at the stage of warming up the steam room. In this case, the heating time will increase, but it will be uniform. If you leave the valves open, the bastu will dry out and overheat the steam room. You can try to "turn on" the bass at the last stage soaring - the air will be light, hot, you can breathe freely. Great ending to a run.

Bastu in the Russian bath useful for drying after procedures- she copes with this perfectly and there will be no smells, no mold with such drying.

The floor in the bath needs to be completely dried after the procedures. The first condition for this will be the organization of the correct flow, with a slope that will divert water into the sewer. Of course, there are several floor options.

For pouring (wet) floors, ventilation is especially important. Therefore, the gaps between the boards, reaching a width of up to 1 cm, are needed not only to drain water, but also to dry the boards. And the opening of the air in the foundation will help in this, which we will discuss below.

A dry floor does not imply gaps between the boards, because it is mounted from a tongue-and-groove board. So, the principle of its ventilation is somewhat different. Drying will have to be done from above by means of burst ventilation (this means opening all windows and doors) and the system that is provided in the bath, for example, forced supply and exhaust.

Look at what dampness can lead to on a dry floor, even if it is covered with yacht varnish:

The ventilation riser in the washing room will be discussed below, but it also affects the ventilation of the floor.

And the floor is well blown during the operation of the furnace, if (as already mentioned), raise its level above the blower, and leave small gaps between the boards in the floor itself.

Actually, everything starts with it, because it is mounted when laying the foundation. To do this, scraps of asbestos-cement pipes are taken, filled with sand and, in this form, are laid among the reinforcement, fastened with a knitting wire between the rods at a height of 5 to 12 cm above the ground. After stripping, the sand is removed.

There can be two such holes in total, laid on opposite sides of the base. However, in reality, it is necessary to take into account a number of various factors, on which both the number of holes and their diameter ultimately depend. By the way, the usual diameter is 11 cm.

See what the lack of vents for ventilation of the floor and foundation can lead to:

Before designing ventilation, take into account:

It is clear that if the bath in the lowland or around solid buildings, more holes must be made, and even from all sides. You can also increase the diameter, but put a grille-blinds or damper.

CAREFULLY! Rodents can get into unprotected vents, so it is recommended to also tighten them with a metal mesh.

Holes provided with plugs are usually left closed during procedures, but they are opened to dry.

Due to differences in the temperature and humidity conditions of each of the bath rooms, ventilation in them is organized differently.

The washing compartment is the wettest, so it is recommended to equip it with a ventilation riser, which is located in the corner, under the floor. This is an asbestos-cement pipe, which is then brought to the roof and supplied with a deflector from above. Ventilation in the sink occurs due to the pressure difference between the room and the end of the pipe above the roof, the air tends to the outside, carrying excess moisture with it.

The reason why you have to bring it to the roof is simple: if moist air is immediately driven out into the street, then the wall where this hole will be located will quickly deteriorate from the outside.

Attic ventilation is a special song. It is done at the stage of installation of the roof.

1- ceiling 2- spotlights 3- roof ridge

IMPORTANT! It is not true that for attic ventilation it is enough for a window on the pediment. These windows will not replace the supply and exhaust system in the roof.

Supply holes are made under the roof canopy (between the roof sheathing and the upper part of the wall, where the rafters rest on the Mauerplate), and exhaust holes are made on the ridge. There should also be openings on the gables, but they are small and very high.

It is also important to take into account the ratio between the area of supply and exhaust openings on one side and the total area of \u200b\u200bthe attic. It is optimal that the first be 1/500 of the second. The ratio between the area of supply and exhaust is not 50 to 50, exhaust should be 10-15% larger in area than supply.

This system is suitable for those baths in which the attic is cold. And there are also baths with attics. There, ventilation is also done at a time when the roof is still open from the attic.

For ventilation of the under-roof space (between the roofing material and the membrane), either natural or forced ventilation can be used. But for the functioning of both, aerators and spotlights are needed.

Aerators are installed either on the area of the roof slope, or on the ridge (these are the most effective). They serve for extraction. And the soffits are responsible for the flow of air. These are siding panels for sheathing roof overhangs, some of which must be perforated. The ratio of the area of the ventilation holes and the ventilated area is the same as mentioned above 1/500.

IMPORTANT! The efficiency of aerators will be higher if you install only ordinary or only ridge aerators.

Fans for the under-roof space are used as supply fans. Particular attention is paid to the wiring so that it does not cause a fire.

Some owners of country houses allocate a basement or basement floor for a bath. Such an arrangement of a hot and humid room makes special demands on ventilation, on which the durability of the whole house now rests.

Note that the redevelopment of the former residential or utility premises includes the redevelopment of ventilation. In general, it is more expensive than the bath included in the project of a house under construction.

One way or another, you need do not forget about the ventilation gap between the walls and the insulation. This will protect against damage to the insulation by condensate. But the moisture in the air corridor must also go somewhere. Therefore, for basement and basement baths, professionally made supply and exhaust ventilation is recommended, and it is better not natural, but forced. Both are accompanied by the installation of a basement deflector.

The location of the basement ventilation depends on the specifics of the project and will not be given here. It is also possible to install a special dehumidifier.

A good option would be to choose bastu ventilation - it's not so expensive, but very effective. The bastu device was mentioned above.

If there is a shower cabin or an open shower in the bath, it is worth installing forced ventilation nearby, which will speed up the drying process.

If there is a shower cabin or an open shower in the bath, it is worth installing forced ventilation nearby, which will speed up the drying process.

If we assume that the air flow is provided by the existing supply openings located in the washing room and other rooms, then you can put the fan only on the exhaust opening, which is located near the shower. (You can do the same if there is a bathroom in the bath.)

The dressing room suffers from condensation due to the temperature difference between it and the hot rooms of the bath. That's why ventilation in it is necessary in the same way as everywhere else in the bath. One air is located at the bottom, the other at the top. The lower one is responsible for the inflow of air, the upper - for its outflow. Installation of forced ventilation is not prohibited. In addition, you can ventilate the dressing room with the help of a door and (if any) a window.

In contact with

A well-equipped ventilation system, other things being equal, guarantees, firstly, a long service life of building and finishing materials involved in the arrangement of the serviced premises, and secondly, the comfort and safety of visiting the latter for the user. Particularly relevant is the issue of arranging full and sufficiently effective ventilation in the bath, due to the characteristic temperature and humidity conditions and additional requirements for such buildings.

bath fan

The choice of the optimal type of ventilation system for servicing a bath is a topic for many hours of discussion. For example, there is natural ventilation. The cost of money, time and effort for its arrangement is minimal - the work literally comes down to drilling holes in the walls, installing boxes / pipes and valves / gratings.

Ventilation damper and grille

Ventilation damper and grille  Ventilation grilles for baths and saunas

Ventilation grilles for baths and saunas

However, it is impossible to use natural ventilation to serve all the premises of the bath. Of course, it would be possible to save money, but the disadvantage of such a solution will become obvious with the arrival of the first winter: along with the influx of fresh air from the street, cold will set in, and everyone knows the combination of frosty air with humidity - everything around will simply freeze. Therefore, natural ventilation in some rooms must be combined with other existing options in other rooms of the bath.

If the bath is equipped with a washing room or even a private pool, natural ventilation will definitely not cope with the maintenance of such premises - you will have to equip an exhaust system. And in general, the presence of a forced inflow / outflow of fresh air will be useful for both visitors to the bathhouse and its premises. Recommendations regarding the optimal composition of the air exchange system are given in the table.

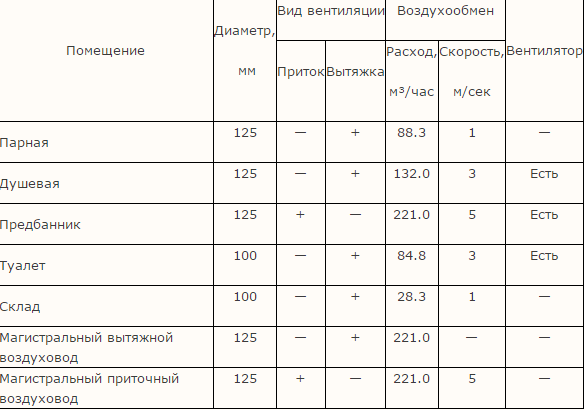

Table. The choice of ventilation system for different rooms

| room | Recommended type of ventilation | Scheme | Description |

|---|---|---|---|

| Steam room, dressing room or rest room | Under aeration it is necessary to understand the organized natural air exchange. The option is most optimally suited for use in a bathhouse: air is supplied from the bottom of the stove (for other rooms - 25-30 cm above the floor), exhaust air is removed through an opening in the upper part of the room. The work of air exchange is based on elementary physical laws: cold air from the street displaces warm air masses, which have less weight, up the room. Aeration is ideal for use in rooms with high heat dissipation rates. The presence of additional moisture contributes to an even more pronounced increase in the efficiency of the system. |

||

| Wash room, bathroom, pool room | The system is equipped with a fan and, if necessary, cleaning filters. Mechanical exhaust ventilation is ideal for use in the washroom, pool room and other damp and high traffic areas of the bath. A mechanical extractor effectively removes unpleasant odors and excess moisture, which makes the air in the served room safe and clean. It is impossible to use only exhaust ventilation - air rarefaction is formed. To compensate for the rarefaction, air is supplied from the street or other rooms. Along with this, the presence of forced ventilation will eliminate the likelihood of drafts. The supply ventilation system can be either natural or mechanical. In combination with mechanical exhaust ventilation, it is more expedient to use a mechanical supply system, because. the potential for natural inflow may ultimately be insufficient to compensate for the resulting rarefaction. At the heart of mechanical supply ventilation is a blower fan. Additionally, it can be equipped with an air heater, which will eliminate the inconvenience and solve the problems of ventilation of the serviced premises during the cold season. Additionally, the supplied air can be humidified or purified using appropriate devices. The mechanical system is more complex in arrangement compared to its analog, which works according to the laws of physics: in addition to fans and air ducts, the system may include additional equipment and devices (diffusers, air distribution grilles, automation equipment, silencers, etc.). This gives an excellent opportunity to arrange an air exchange system that fully meets the wishes of the user. |

In vestibules, warehouses and other premises of a similar purpose, a natural hood is made.

Regardless of the type of ventilation system chosen, the bath must have conditions for simple ventilation. Install adjustable windows in all rooms, the location of which allows this.

For the calculation, an elementary formula is used:

W (required volume of fresh / exhaust air) \u003d k (coefficient indicating the frequency of air exchange) x V (volume of the serviced room, determined by multiplying the width of the room by the length and height).

That is, first you must calculate the volume of each room and find for it the required indicator of the volume of clean air (in calculations it is customary to denote Wpr, i.e. inflow) and a similar indicator of exhaust air (indicated as Wvt, outflow). In this case, multiplicity factors must be taken into account. The calculated values are rounded up - the last digit in the number must be 0 or 5.

Next, the summation of all Wpr is performed. A similar action is carried out for the found Wvt. The amounts received are compared. If the total value of Wpr exceeds the total indicator Wpr, it is necessary to increase the exhaust volume for rooms with a minimum air exchange value, if vice versa, increase the inflow by the missing value. That is, at the output, the sum of all Wpr should be equal to the total value of the found Wvt.

The results of the calculations will allow you to determine the optimal cross-sections of the installed air ducts and choose the appropriate type of ventilation system. Thus, with the calculation of the volume of premises and other related data, there will be no particular problems. For greater convenience of subsequent processing, enter the found values in a simple table, as in the example presented.

In the given example, the total value of Wpr is less than the sum of all found Wvt by an indicator equal to 110 m3. In order for the balance to be maintained as a result, it is necessary to ensure the flow of clean air in the missing amount. This can only be done in the waiting room. Thus, the value of 55 m3 for the dressing room, given in the table, must be replaced with an indicator of 165 m3. Then the balance will be struck.

Proceed to the calculation of the installed air ducts and the drawing up of the structure of the equipped ventilation system.

The ventilation system is designed in such a way that the air moves through the installed air ducts with the following speed indicators:

When choosing the cross-section of air ducts, consider the above indicators. As for the profile of the box / pipe, this moment is determined by the design features of the air exchange and the bath itself. For example, air ducts with a circular cross section are easier to install than their rectangular counterparts, and it is much easier to select the required connecting fittings for round air ducts.

The relationship between the diameter of the air ducts and other significant indicators is shown in the following tables.

For example, we will work with round ducts. We select the necessary sections according to the corresponding table, focusing, at the same time, on the indicators of the table An example of calculating ventilation.

Estimated air consumption is 165 m3/hour. The air flow at this flow rate should not move faster than 5 m/s. In accordance with the table above for round ducts, we select the section according to the specified data. The tabular value closest to ours is 221 m3/h. Air duct cross section - 125 mm.

Air duct with insulation

Air duct with insulation  Flexible ducts

Flexible ducts

In the same order, we determine the optimal sections for all branches of the system in the serviced premises, remembering that in them the air flow should move at a speed not exceeding 3 m / s (in vestibules and closets - 1 m / s, in the steam room - 2 m / s). sec):

Important! In the shower room (washing room, room with a pool), an increased level of humidity is noted. When determining the cross-section of the duct for this room, it is necessary to make an upward adjustment (in this example, 125 mm).

For greater convenience, enter all the information received in the table. As an example, you can use the template below.

Important note! In the table above, the extract volume exceeds the clean air supply. This happened because the sections were determined by the nearest flow rate, and the diameter of the air duct in the washing room was deliberately increased. In practice, such an approach will only benefit - the margin for outflow and inflow will not be superfluous.

SNiP 2.08.01-89. Residential buildings. Download file

Sanitary and epidemiological requirements for residential buildings and premises. Sanitary and epidemiological rules and regulations SanPiN 2.1.2.1002-00. Download file

Building codes and regulations of the Russian Federation heating, ventilation and air conditioning heating, ventilation and conditioning SNiP 41-01-2003. Download file

The cross-sectional area of the ventilation window is determined in accordance with the volume of the served room: 24 cm 2 for every 1 m3.

It remains to figure out only the optimal height of the ventilation holes:

Only options for arranging ventilation in the steam room deserve special consideration - in the rest of the rooms everything is done according to the standard scheme, for example, like this:

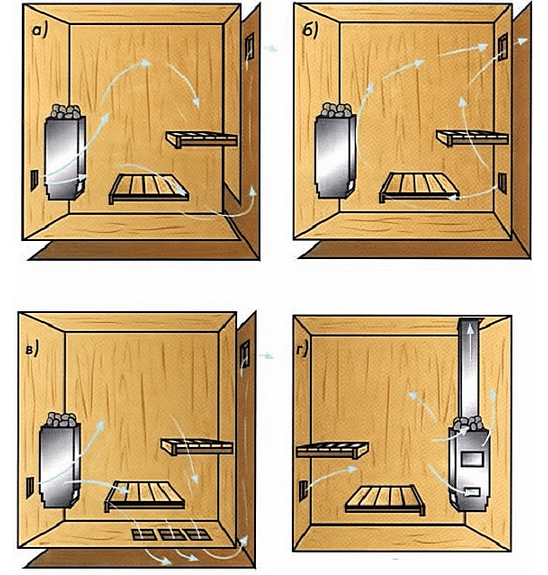

Air exchange in the steam room can be organized in accordance with 4 main schemes presented in the following image.

Scheme "a". The most popular option. The window for air flow is next to the stove, at a distance of about 25-30 cm from the floor. The incoming clean air gradually displaces the exhausted warm upwards to the opposite wall. On it, about 15-25 cm below the ceiling, there is an exhaust hole.

Scheme "b". Both holes are on the same wall. The circuit will only work if an exhaust fan is installed. Fresh air enters through the lower opening, equipped in the wall opposite to the stove. The air will rush in the direction of the stove, and then, covering the space of the steam room with an arc, move to the hood and be discharged outside the bath.

Scheme "in". The option is suitable for steam rooms with a leaking floor. The inlet opening is located as in scheme "a". After warming up in the upper part of the steam room, the air descends to the floor, passes through the gaps in the boardwalk, contributing to more efficient drying of the boards, and then is removed through the exhaust hole, usually equipped in another room. Also, the hood can be carried out through a separate insulated channel.

Scheme "g". Option for baths with a constantly working stove. In this case, the function of the hood is performed by the blower hole of the furnace. The supply window is arranged under the shelf, in the wall opposite to the furnace. The height of the inlet must correspond to the height of the furnace blower. Fresh air rushes to the stove, displacing the air masses heated by it to the ceiling. Cooling down there, the air descends and is removed from the bath through the blower.

In order for the operation of the air exchange system to be as efficient and high-quality as possible, before starting its installation, study and remember a few simple tips.

If your bath has a bathroom or even a kitchen, equip them only with exhaust ventilation - this solution will eliminate the possibility of unpleasant odors spreading to other rooms. Alternatively, you can equip other rooms with forced ventilation, and equip the bathrooms with a natural exhaust - in this case, the air will move towards the bathrooms.

When calculating the performance of fans, it is recommended to reduce the total capacity of the supply units by 5-10% of the total performance of the exhaust units. In this case, the exhaust air will be completely displaced by the incoming air masses, and a 5-10% margin will compensate for the inflow of air entering through windows, slots, etc., which will allow you to maintain a balance.

In rooms with only natural ventilation, it is recommended to definitely make opening windows - this will increase the efficiency of fresh air intake and reduce the risk of fungi, mold, rot, etc.

Important! If your bath has a non-standard configuration, the ventilation system project will also be individual. When compiling it, the features of the composition of the premises, their design, design features, etc. should be taken into account.

Any ventilation system in any room is equipped in approximately the same sequence. Differences are present only in the characteristics of the air vents and their locations, as well as the configuration of the system (mechanical, unlike natural ones, are supplemented by various kinds of devices).

For example, the following arrangement of ventilation elements can be used.

Or its somewhat modified counterpart, shown in the following image.

Recommendations regarding the choice of the location of each opening, the type of air exchange system for different rooms of the bath, as well as the procedure for determining the characteristics of the ventilation elements, were considered earlier.

Along with this, the procedure for arranging ventilation may vary depending on which design option you prefer. There are few solutions available:

A reasonable option for use in a bath is independent ventilation - the owner can choose the optimal characteristics of fans and other elements for each room, saving money, time and effort on the activities necessary to combine the channels into a single system.

Important! The location of some bath rooms may not allow to equip independent supply and exhaust ventilation. In this case, it will not be possible to avoid laying ventilation ducts. Alternatively, the boxes can be placed in the attic, and the ventilation holes can be arranged in the ceiling or connected to the channels equipped in the walls (the option is more complicated if the laying of such channels was not provided for by the project at the construction stage of the bath).

In most cases, the first option is used: ventilation pipes of the required length are led out through openings in the ceilings of the serviced premises and either equipped with their own fan, if necessary (easier to implement for an unprepared user, the procedure is similar to that given in the following table), or connected into a single circuit and connected to a common hood (may require the involvement of specialists).

Remember: the maximum efficiency of the ventilation system is ensured by using as short and straight air ducts as possible - up to 3 m with natural air exchange and up to 6 m with electric fans.

The procedure for arranging an independent ventilation system is given in the following table.

Important! The example considers instructions for arranging a mechanical ventilation system using fans. The order of installation of natural air exchange remains almost the same: only the stages of laying wires and installing fans are excluded.

Table. Arrangement of ventilation

| Stage of work | Explanations |

|---|---|

| The operating procedure remains the same for the supply and exhaust openings. Only the height of their arrangement and location change (possible options were considered earlier), as well as the type of fans used (supply or exhaust). The characteristics of the latter are selected on an individual basis, taking into account the volume of the serviced premises, the required air velocity in the air ducts, the required air exchange rate, etc. - all these moments were consecrated in the theoretical part. We equip the holes in the following order: - we outline the center and contours. We make the markup so that the diameter of the hole as a result slightly (usually a 2-3 mm gap is made) exceeds the diameter of the installed pipe (recommendations for choosing the diameters of the ducts were given earlier); - Using a perforator, make a hole in accordance with the markings. We hold the working tool horizontally, but with a slight downward slope; - carefully take out the cut material (a hammer and a chisel will help us with this), after which we carefully clean the finished hole from dirt and dust. |

| The ventilation pipe (ventilation duct housing) is placed in the prepared hole, but before that it (if mechanical / forced ventilation is planned) must be equipped with a fan. Useful recommendation! Initially, buy ready-made kits for arranging ventilation, including, in addition to related accessories, a ventilation duct / pipe and a fan with an appropriately sized case - this way you will avoid difficulties during the assembly stage. The pipe with the fan is placed in the prepared hole, and the remaining gaps are filled with mounting foam. |

| The fan is an electrical appliance, therefore, it must be connected to the mains. Let's do this while the mounting foam dries (at least 10-12 hours). The procedure is standard: - the contours of the strobe for the cable are cut out in the wall using a grinder. Excess material is removed using a chipper; - a hole is prepared in the wall for installing the switch box (for example, you can use a puncher). The box is installed (pre-read the instructions specifically for your switch). The switch itself will be mounted after finishing; - the wire is laid in a strobe. We use alabaster to fix the cable; - connect the wire to the switch and fan. We must first study the connection diagram recommended by the fan manufacturer in the attached instructions, because. it may differ for different devices. For example, one of the most commonly used schemes is given. |

| It remains only to bring the whole structure into its proper form. To do this, we do the following: - get rid of excess dried mounting foam with a knife; - putty strobes; - we mount adjustable ventilation grilles on both sides of the pipe. For fastening we use self-tapping screws. If provided, we install additional elements at the appropriate stages of work (for example, an air heater, a filter, etc.). Each of these devices is mounted individually - we first clarify these points in the manufacturer's instructions. |

We will send the material to you by e-mail

Proper implementation of the appropriate design improves the performance of the facility and ensures a high level of safety and comfort. Properly designed ventilation will help extend the life of the building. After reading this article, you will find out if ventilation is needed in the bath, you will be able to create the necessary design with your own hands. Here you will find information about materials and individual components, installation and construction technologies. Professional advice will help eliminate errors and reduce costs.

High-quality ventilation is one of the most important components of a good bath.

To accurately determine the parameters of the project, it is necessary to clarify its intended purpose. Creating for a bath allows you to solve the following practical problems:

Of course, the operation of this system should not worsen other consumer characteristics of the building. For example, if the intake of cold air is excessive, the cost of maintaining a high temperature will increase.

This list of actions will help you figure out how to make ventilation in such a way that you do not miss important points:

For electrical wiring, a suitable cable is used that provides reliable insulation even when immersed in liquid. The switch is installed in the rest room, or in another room with a normal level of humidity.

For ventilation in the bath sink, you can use a small window or a special channel. In any case, it is necessary to configure the system in such a way as to exclude drafts. You can combine the supply parts here and in the steam room to increase the air temperature and provide ventilation for wooden flooring.

In this room, the organization of fresh air access does not differ from a similar system in an ordinary living room. The use of natural and forced ventilation in various combinations is available. It must be remembered that hypothermia provokes the occurrence of colds and other diseases.

Note! Log houses have special features. They create comfortable temperature conditions in rooms without special technical means due to the natural micro-ventilation of the walls. For intensive ventilation, you can open doors, windows.

Related article:

In a separate publication, you will learn about the most successful layouts of baths with an extension in the form of a veranda or terrace.

In this section, the architectural features of the structure are studied in detail. Proper ventilation in the bath should not have a negative impact on the structural parts. Moreover, it creates favorable conditions for extending the service life without major repairs. In order not to make a mistake and not to take unnecessary actions, an appropriate system must be created at the design stage. An example with a concrete foundation illustrates the convenience of mounting holes using embedded parts. Their drilling in a frozen block will be accompanied by significant difficulties.

The gaps between the frame elements are filled with mineral wool. It is covered with a polymer film to prevent moisture from entering. Outside - install lining, with painting, other finishing coatings.

Such a design can be created quickly, at minimal cost. A light structure does not need a strong foundation. The multilayer construction of the walls has a low thermal conductivity, which reduces operating costs. In order not to violate their tightness, ventilation channels in the frame bath are installed in advance, along with the installation of structural structural elements.

Note! If you use polyurethane foam boards, the cost of the project will increase slightly. But in this case no special precautions are needed. The insulating properties of these materials do not deteriorate in conditions of high humidity.

To correctly determine the ventilation parameters in a wooden bath, the following features must be taken into account:

Note! Such buildings are installed on a strip foundation. The base of the floor is made of concrete. In these elements, holes are created at the stage of pouring the solution.

Related article:

In a separate publication, you will find interesting ideas for finishing steam rooms and rest rooms, as well as learn the main installation steps.

Structures made of these materials are highly resistant to various types of external influences. They are able to withstand heavy loads without damage. They are not destroyed by changes in temperature and humidity, harmful insects and microorganisms. In the absence of flammability, special measures are not needed when installing power lines.

In order not to use such heavy operations, the necessary passes are made during the masonry process. For the exact performance of work, marks are made in the design documentation. At the stage of project preparation, the parameters and installation lines of electrical networks are determined.

This technology has been used in Sweden for hundreds of years. It provides efficient ventilation of rooms without electric drives. An additional advantage is the economical consumption of thermal energy.

The figure shows a system for two rooms. In the steam room, air is supplied to the space under the furnace. With the help of a special casing, the basic principle of the technology is implemented: “inverted glass”. The heated air stream under pressure enters the rooms. Output paths - as in the standard version, through the box, with a fence from the lower parts of the rooms. The use of bastu ventilation in a Russian bath will allow you to quickly dry the floors. Pay attention to the separate inflow installed in the rest room. With the help of a metered supply of cold / warm air, you can maintain comfortable temperature conditions at any time of the year.

Before proceeding to the study of individual elements, it should be noted the principles of operation of ventilation of different types:

When choosing forced ventilation, it is necessary to correctly use the appropriate electrically driven technology.

When choosing suitable products, the climatic conditions in the region are taken into account. For the northern regions, triple-glazed windows are installed with good insulating characteristics. If plastic frames are purchased, you need to check the number of cameras.

To avoid fogging, you can use the data from the following table. The values in it correspond to the temperature outside, at which droplets of moisture condense on the inside of the glass:

| Room temperature, °C | Humidity, % | |||||

|---|---|---|---|---|---|---|

| 20 | 30 | 40 | 60 | 80 | 100 | |

| 0 | -20 | -15 | -12 | -6,9 | -3,1 | 0 |

| 5 | -15,8 | -11 | -7,5 | -2,2 | 1,8 | 4,8 |

| 10 | -11,8 | -6,8 | -2,8 | 2,7 | 6,8 | 10,1 |

| 15 | -7,6 | -2,5 | -1,4 | 7,4 | 11,7 | 15,8 |

| 20 | -3,7 | 1,8 | 5,9 | 11,8 | 16,3 | 20,1 |

| 25 | -0,4 | 6,1 | 10,4 | 16,6 | 21,2 | 24,8 |

When choosing an installation location, enter the dimensions of the block in the opening with the following gaps:

It is necessary to take into account a significant change in the size of the opening in a wooden structure. To prevent damage to the frame, special damping elements are installed. In brick buildings, such precautions are not needed. The doors must be free to open. If necessary, other curtains are installed from the inside.

Note! In order to avoid damage by high temperature and to prevent deterioration of the composition of the atmosphere, windows are not installed in the steam room.

The forced system is installed with a large area of \u200b\u200bthe premises. It will be needed in a building made of brick, or other materials that do not allow air to pass through.

When choosing a fan for a bath, check the following parameters:

The video below explains the DIY fan installation process. This instruction can be used for the installation of equipment in the bath, bathroom, toilet.

The non-return ventilation valve for the bath does not allow cold air to pass through from the outside. Similar phenomena can occur, for example, in strong winds. The figure shows that the damper is moved by a counterweight. There are no electric drives and other complex components, which explains the relatively low cost.

Valves are selected according to different needs:

The optimal air flow path helps to correctly determine the installation parameters of the inlet and outlet. If the air in the bath is set at the same level, the desired effect of uniform heating will not be obtained. The stream will take the shortest path, creating a draft. It is also recommended to consider the following points when planning:

Nice, heat-resistant diffusers

Article

Greetings, dear host. You built a house, gave birth to a son, planted a tree near the house, it's time to think about health. Yes, yes, about your health, and your family. It's time to build a bathroom!

How to build, from what materials, where to choose a place - you decide - you are the owner, and I will talk about, probably, the most important and important part of the construction - ventilation. Ideally, the calculation and organization of the ventilation system should be carried out at the construction planning stage. But in real life, there are many options:

Building a bath without ventilation is not a rare case, you should not sprinkle ashes on your head and think that you are stupider than others. Not at all, at least you remembered, and this is already something. Adjustment of air circulation is possible, even if it has not been provided.

It is not advisable to rely on burst ventilation: the accumulated heat does not go away with the door open, but, according to the laws of physics, turns into steam and settles in the form of condensate on the walls and floor. Hello fungus! It’s a pity, of course, because redevelopment, and this is what it is, will cost a pretty penny. And when in the house? What about a brick house?

The diameter of the ventilation carried out affects the quality of the process: a small traction force will not allow the entire system to work fully, which will nullify all the work done, and an excessively powerful traction, on the contrary, will not allow creating the optimum temperature. Proper ventilation requires compliance with indents:

Yes, definitely yes. This famous and very useful building is being erected with the main goal: recovery. Steamed skin allows accumulated toxins and dirt to pass through it, while saturating the body with oxygen, and what kind of oxygen are we talking about in a tightly sealed room?

A steam room without ventilation is more like a hyperbaric chamber with carbon dioxide; within a few minutes, unbearable heat and lack of oxygen will drive you out of the steam room. To arrange an outlet with a natural outlet, forced exhaust - depends on the technical and your capabilities. The main thing. The hood from the stove, it is gas, wood, must have a separate overpass.

The Russian bath differs from the sauna in the principle of operation of the steam room, the method of heating and ventilation. The bathhouse was heated "in black" and "in white". In the first version, the stove was heated, the stones laid on top of the hearth were heated, the burnt coals were raked out and carried away, the heat came from the stones, the outflow of air occurred through a door or window. In the second version, the stove worked during the park, the smoke came out through the chimney, and excess heat also went through it. In a modern bath, in addition to the chimney, additional exits are used.

There are many options: in the finished room, connect the steam outlet of the vent to the existing air ducts, through other rooms, when the wiring goes inside the house, bring a separate pipe to the street by drilling a hole in the wall.

The location of the holes varies depending on the desired result: the hood is lower - the temperature rises faster, higher - better air circulation.

Basement. The steam room is ready. The only opening is the front door. Already good. For the organization of forced ventilation we use it. It's easier - cut a hole at the bottom of the door with a jigsaw, put blinds, grating.

Better - in front of the door, from the side of the steam room, build a box with outlets from sewer pipes under the stove and to the side. Use the grate with a valve - in winter, the air is colder, warming up the room will take longer.

The air flow from under the furnace will rise up, capturing heat, and an additional draft of fresh air will go from the pipe laid aside (in winter it can be tightly closed with a valve). Next, we cut a window to Europe. Kidding. Outside.

From the outside, we mark the approximate place where you need to make an extract. Above the ground - lucky, below the level - we remove the soil, make a dig (so as not to miss, it is better to take it wider). A concrete wall or masonry can be drilled with a special tool. It is unlikely that he will be found by a non-specialist.

Alternatively, rent a tool. You go to the Internet, open sites that specialize in such a service, and place an order. But you and I are simple people, we will break through. A puncher is not a rare thing, I have it, I think you will also have it.

We go down to the basement again. I managed to sheathe the walls - nothing, we will remove the sheathing. On a bare wall, mark the place where the pipe exits with a marker. Be careful with the diameter! Above, I already gave the calculation formula. You can take a piece of pipe and circle around. Silently stepping back along the perimeter of the circle (the hole should eventually be slightly larger than the diameter of the pipe), a through hole is drilled with a perforator, after 2-3 cm the next one, and so on in a circle.

With a chisel you break the formed jumpers - that's it, the opening is ready. You take out the remains of the wall, trim the edges and walls of the tunnel, and try to advance the pipe. Happened? Cool. No - pay attention to what interferes, bring down the excess.

When the wall is made of timber, the technology for cutting the opening is the same as on brickwork, with a small difference: instead of a chisel, a jigsaw is taken. Sewer pipes are not suitable for an exhaust pipe, galvanization is required.

We insert the segment into the opening, fill the voids with insulation (glass wool, mineral wool), sew up the walls with wood. The gap between the casing and the pipe must be foamed. We make a box. It is needed to regulate the degree and height of heating the room. The thickness of the box corresponds to the diameter of the pipe with which it is connected, the length depends on the height of the steam room. Two windows are cut out on the box, which are equipped with a blind valve. One window is located about twenty cm from the ceiling, the lower one is 50-60 cm from the floor.

When the stove is heated, both exhaust dampers in the steam room are closed, as a result, the lower one opens first, and then, if necessary, the upper one. So you can easily adjust the temperature right during the procedure.

Using the built-in fan will improve the outflow of hot air from the room. Don't forget about gratings at the outlet of the duct to keep dry leaves and other debris out. By the way, it is necessary to clean the hood at least once a year.

Bastu has become widespread. The system has taken root due to the ease of installation and efficient heat distribution. Only now it is better to mount it initially, at the construction stage. The above scheme and the device for circulating air flows are fundamentally different from those described by me in this article earlier.

The bastu principle is an inverted glass. As you can see, both the supply air duct and the outlet are almost at the same height - just above the floor level.

The lower pipe, through which air enters the steam room, originates from the street, the outlet is located behind the stove - in fact, this is the thrust. The heated air outlet is located strictly diagonally from the stove, located below the bench. Warm air from the stove rises, creates increased pressure under the ceiling, and cools down a little in the opposite corner and, descending, enters the ventilation.

The main difference is approximately the same air temperature along the height of the room, while in the Russian bath the upper bench is hotter, and the lower one is more comfortable.

When the heated air masses rush to the lower point of the exhaust, they will take heavy moist air with them and dry the floors faster.

The downside here is the dependence of effective work on the strength of the wind on the street, when the air blown into the exhaust pipe interferes with the natural outflow, moreover, it can reverse it. Then the steam room will be filled with the smell of burnt fuel, which will not allow you to get the proper result from the procedures.