After purchasing timber, it must be carefully inspected. It is better to replace wood with chips, cracks (especially at the ends) and fungus with high-quality ones. If this is impossible, then immediately begin antisepticizing it. Moreover, they also process high-quality wood, which can be infected with fungus. Before processing, the ridges and logs are cleared of bark, the affected wood is scraped off and burned, the remaining wood is dried and the tools are disinfected.

Then an antiseptic is selected, which should not destroy the wood and complicate its finishing, cause metal corrosion, or have bad smell. Before using it, you should put on a tightly fastened robe, preferably a special overall, a rubberized apron and rubber gloves, and safety glasses with a respirator. Instead of a respirator, you can use a gauze bandage with a layer of cotton wool, pre-moistened. Food should be temporarily removed from the premises and people, birds and animals should be removed. After work, it is recommended to wash your face and hands warm water with soap.

Antiseptics dissolve in water or oil. Water-soluble are practically odorless and are found wide application V individual construction. Treatment is carried out with a brush and sprayer. The most common antiseptics are sodium fluoride and fluoride, as well as ammonium fluoride.

Sodium fluoride is a white, odorless powder. It does not stain wood, does not reduce strength, and metal corrodes. Solubility in water at a temperature of 20 °C - 3.7%, 80 °C - 4.6%. Solutions of 3...4% concentration are used.

Sodium silicofluoride is a white or light gray powder with a yellowish tint. Solubility in water at a temperature of 20 °C - up to 0.7%, 80 °C - up to 1.8%. Should be used with soda ash, sodium fluoride or liquid glass. These two drugs considered cannot be used in a mixture with lime, chalk, gypsum and cement, since they then lose all their basic antiseptic properties.

Ammonium silicofluoride is a white, odorless powder. It does not stain wood, does not reduce its strength, and gives it low fire resistance. Toxicity is higher than that of sodium fluoride. Solubility in water at a temperature of 25 °C - up to 18.5%, 75 °C - 32.5%. Typically, solutions of 8% concentration are used. The disadvantage of an antiseptic is that it is easily washed out with water.

The wood is antisepticized three times at intervals of 2...3 hours, but it can also be done after a longer time. In this case, the wood is impregnated to a depth of 1...2 mm.

There are antiseptics against insects different names and appointments. For example, one of them - chlorophos is mixed with water in any ratio. It has a sharp but quickly disappearing odor. It is better to use solutions of 10% concentration.

After urgent antiseptic treatment choose a place for storage and warehousing building materials, taking into account that when major renovation storage will be long-term, and in case of current or preventive storage - short. In the latter case, the premises of outbuildings can be adapted for warehousing and storage. personal plot. However, for one reason or another, storage may drag on and turn into a long-term one. Therefore, it is best to choose a site for storage and storage of building materials on a personal plot (Fig. 1.8). It is positioned so that a car can easily drive up to it and no water can approach it.

Rice. 1.8. Example most convenient location areas for storage and storage of prepared building materials on a personal plot: / - area for storage of building materials; 2 - reserve site or for storing fire and explosive materials; 3 - residential building; 4 - garage; 5 - utility road; 6 - porch; 7 - palisade; 8 - veranda; 9 - terrace; 10 - utility site; // - barn; 12 - you - the hum of a bird; 13 - passage for cattle walking; 14 - toilet; 15 - storage shed; 16 - inventory warehouse; 17 - vegetable garden; 18 - garden; 19 - flower garden; 20 - fence; 21 - street; 22 - neighboring area; 23, 24 - runs for livestock; 25 - car entry; 26 - entrance; 27 - loading construction materials

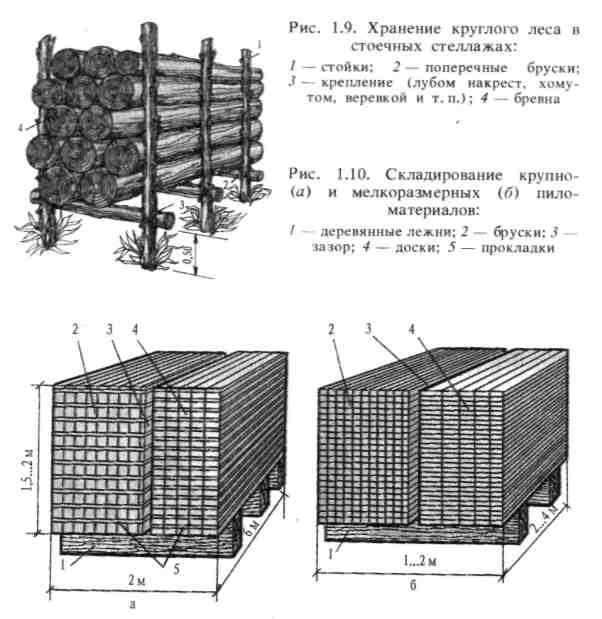

For storage round timber arrange special racks (Fig. 1.9), consisting of vertical posts and transverse bars (or poles), attached at a height of 45...50 cm from the ground, or a platform with a waterproofing bedding.

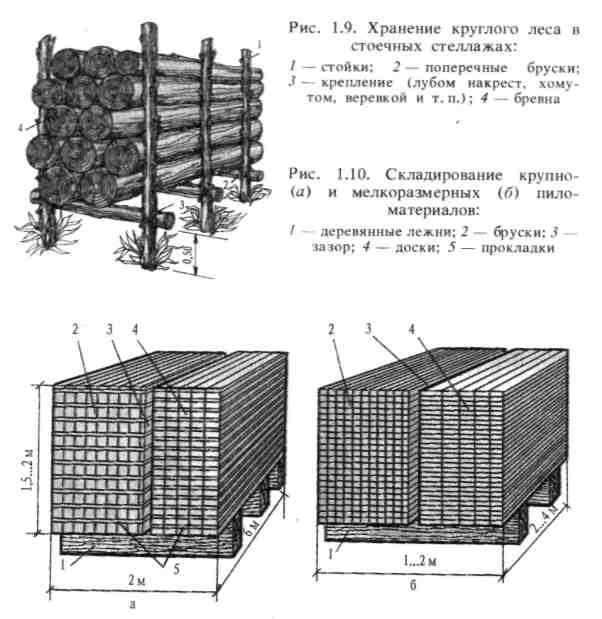

Lumber is stacked on beds with dry pads made of the same type of wood (Fig. 1.10) in a well-ventilated place. There should be at least 20 cm from the surface of the ground to the bottom row of lumber in the stack.

Before laying, the material must be sorted according to profile. This allows you to clarify the volume of a given material of the corresponding profile and facilitates access to it without unnecessary re-arranging.

At negative outside temperatures, lumber is stacked in stacks with vertical gaps (wells) measuring at least 10 X 10 cm for semi-dry wood and 20 X 20 cm for dry wood. A sloping roof is installed on top.

In conditions high humidity and in the absence of proper ventilation and waterproofing, wood can quickly become again affected by fungi and rot. Characteristic sign- cotton wool-like clusters of thin threads white, which then, growing, form films and strands with a silvery tint and droplets of moisture on them.

When you rub a piece of mycelium, a strong smell of fresh mushrooms spreads. At the same time, the wood changes color - it darkens, cracks, becomes loose and light, and loses its strength properties. In almost a few months, fungi can completely destroy wooden blanks and products. To prevent this unfavorable phenomenon, dampness should be avoided, since in dry wood all fungi die and the rotting process stops.

Due to the difficulty of creating appropriate ideal storage conditions before stacking on racks, it is recommended to repeat the antiseptic treatment of timber. To do this, use a 10% solution of copper and iron sulfate (50 g of each preparation per 1 liter hot water), as well as a mixture of this solution with milk of lime and clay.

Deep impregnation is more effective. Surface treatment must be repeated, usually after a month. Larvae and beetles die after three to four treatments, carried out every two weeks. During the year, wood dust can be removed from the holes with a thin wire and an antiseptic can be injected into them.

Treated engine oil from cars, diesel locomotives, etc. can also be used as an antiseptic. It is applied two to three times at intervals of one week. Moreover, after the first treatment, there is a significant decrease in the vital activity of fungi, suppression of their growth and drying out.

In addition, the following compositions can be used for antiseptic use: tree resin and chalk (33 parts each), drying oil and fluffed lime (17 parts each) or tree resin (83 parts) and fluffed lime (17 parts).

In order to protect the ends of the logs from cracking, it is best to paint them after secondary antiseptic treatment with lime or coat them with a clay liquid mortar. Then stack the logs with spacers between the rows and cover the end sides with panels made of roofing felt, roofing felt or straw mats. First, remove the bark from the pads.

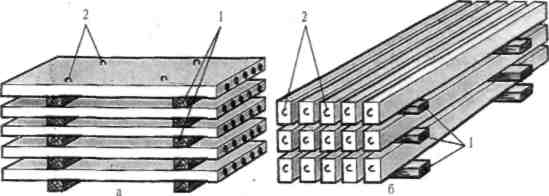

Sheets of glass are stored on rubber, felt or wooden pads with an angle of inclination to the vertical of 10... 15°. Boxes with glass are also stored in an inclined position.

The bricks on the pallet are placed with cross ligation and “in a Christmas tree”. When tying “in a Christmas tree”, the brick is laid with an angle to the center of the package at an angle of 45°, so the package does not fall apart during transportation. This allows you to use ordinary cars or trailers and even hand trucks for transporting packages without additional sides or fastenings.

Sand-lime brick transported in packages on specially equipped vehicles or platform trolleys corresponding to the size of the package.

If the brick is delivered to you without containers or packages, then it is unloaded manually, placed in special stacks up to 1.6 m high or on pallets. In this case, bricks with non-through voids are placed with the voids facing down so that water does not collect in them, which, if frozen, can destroy it. Facing bricks are stacked in regular rows according to grades, colors and shades.

The height of the stack should not exceed 1.5 m. A canopy is installed over the stacks.

Ceramic wall and facing stones, as well as stones from other materials, are unloaded, stored and stored in the same way as facing bricks. Facing products from ceramic, concrete and other slabs are laid in 2...3 rows on an edge with the front surface facing each other and stored in containers or stacks on wooden pads. Facade tiles small sizes are stored in containers, and facing architectural details- laid on linings in one row in height.

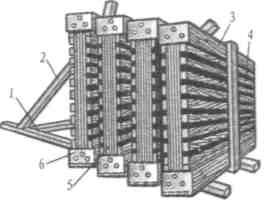

Reinforced concrete elements and parts are installed on wooden inventory pads, placing them in places provided at the storage site. Spacers between products stacked are placed one above the other (Fig. 1.13). The thickness of the gaskets, which must be at least 25 mm, is selected so that the elements do not rest on hinges or protruding parts of the underlying elements. The pads usually have a cross-section of at least 100 X 100 mm.

The areas for the stacks are pre-leveled, the soil is compacted so that the pads do not sag. Otherwise, the product will rest not on the pads, but on the ground and will break due to improper distribution of loads.

Foundation slabs and basement wall blocks are placed in stacks no more than 2600 mm high on pads and gaskets, which are installed at a distance of 300...500 mm from the ends of the blocks.

Rectangular crossbars (purlins) up to 600 mm high are laid on edge, no more than three rows in height, with pads and gaskets located at a distance of 500... 1000 mm from the ends.

Hollow-core floor slabs and roofing slabs are laid flat in stacks no more than 2500 mm high. Gaskets and linings are placed perpendicular to the voids at a distance of 250...400 mm from the edges of the slabs.

Flights of stairs are stored steps up. Linings and gaskets are placed along the flights at a distance of 150...200 mm from their edges.

Landings are placed in a horizontal position, pads and gaskets are installed at a distance of 150...200 mm from the ends.

Large-panel room partitions are stored in a vertical or slightly inclined position.

Products must be stored in such a way as to prevent contamination and damage. front surface. They should not be placed on pads or pads covered with ice. To prevent water from stagnating on the structures, they are tilted slightly. Through holes in concrete products are closed to prevent snow and water from getting into them. Reinforced concrete parts are periodically cleared of snow to prevent them from icing.

Cementing materials and additives for mortars have different terms storage

When storing cement, it must be taken into account that it loses its strength over time. For example, the strength of Portland cement after 3, 6 and 12 months will decrease by 20, 30 and 40%, respectively. To prevent the strength from decreasing, immediately after purchasing the paper bag with cement, you should pack it in a plastic bag or wrap it in film. The binder material, protected from moisture, is well preserved for several years.

In winter, lump lime can be stored in closed sheds in stacks on a layer of sand or fluff lime 5...6 cm thick. To prevent it from extinguishing, the top and slopes of the stacks must be covered with a layer of fluff lime 5...10 cm thick.

Boiler slag, sometimes used as a filler in concrete, must first lie in dumps for at least one year. This is necessary so that sulfur is washed out of them, which greatly destroys the binder material. The slag can be scattered in a layer of 10...20 cm and watered with water from a watering can for several months as it dries.

In this case, it is recommended to crush large pieces of slag beforehand. There should be no more than 10...20% of unburnt coal in the slag, but it is better to get rid of it completely. Slags must be clean, free from rags, metal inclusions, earth and stones.

Fine slag from coal, which serves as a good insulation for floors in wooden houses, before use, it must be kept in the open air for at least 6...8 months in order to completely remove the sulfur smell from it. Then it must be dried and, if necessary, crushed.

Lastly, drying oils, pigments, oil and enamel paints, as well as varnishes and polishes, that is, fire and explosive building materials, are brought to the warehouse site. It should be stored isolated from other flammable materials, in a special compartment and packaging with all precautions.

Purchase building materials for the construction of a house, summer house or cottage, this is only half the battle. Building materials are exposed to low or high temperatures, snowfall, rain, which render them unusable over time. Therefore, it is necessary to ensure their correct storage on construction site. Developers should know what to pay attention to so that valuable acquisitions are safe for a long time. We offer a number practical advice By storage of building materials at the construction site of his house being built.

First of all, storage areas should be determined and prepared in advance. The selected area must be leveled, compacted and water drained so that it does not accumulate in this place. To level the area, it is best to use sand or fine crushed stone(pebbles), which allow water to easily penetrate the soil. The area should also be well ventilated to ensure ventilation of stored materials. It is unacceptable for materials to rest on fences, buildings, poles air lines power transmission During storage, maintain a minimum distance of 0.75 m from a fence or building and 5.0 m from the construction site itself.

Methods for storing individual building materials and construction products depend on their resistance to atmospheric influences, such as temperature, solar ultraviolet radiation, air humidity and the like. On construction sites, the storage of building materials is mainly open, i.e. not requiring protection from precipitation. However, some types should be protected from rain, snow and sun rays, but they do not require maintaining a certain temperature or humidity. For this case, a semi-closed warehouse is erected at the construction site in the form of an attached light canopy or covered with a tarpaulin, sheet metal or synthetic film. Still, a significant part of building materials needs improved conditions - storage in closed warehouses. A shed made of second-rate wood, a garage, a cellar or an old one can serve as a warehouse. non-residential premises. Here it is advisable to store mineral wool, polystyrene foam, rolled metal, and construction chemicals. In addition, plaster mortars, glue, waterproofing, liquids and other similar building materials in winter period at negative temperatures may freeze and lose their properties when thawed. Untreated metal may rust. It is best to hide construction equipment in a dry and safe place. If possible, do not leave it at the work site because it could become a valuable target for thieves.

These are the most popular bulk building materials, packaged in bags that can be stacked in up to 10 layers, one on top of the other, crosswise. Bulk building materials are stored in a dry and closed room in winter. The minimum distance from the walls to bags of cement is 15 cm, and gypsum-based mixtures are 0.5 m. The flooring on which the bags are laid is raised from the ground level by 15-20 cm.

For this purpose, it is better to use pallets or wooden floors on joists. The problem with storing these building materials is that they actively absorb moisture from the room. If the protective packaging of the bags - kraft paper or polyethylene - is damaged, the mixture begins to become saturated with moisture and ultimately turns into a solid monolith that is not suitable for further use.

Bags with an intact shell can be stored for 6 to 8 months by following additional protection- wrap each bag with plastic film.

They are stored by pouring them into separate piles on a flat area (preferably with concrete base) with a slope to drain rainwater.

Depending on the type of brick, there are different approaches to storing it. Remember that storing bricks in bulk will lead to the appearance of cracks and chips on it and, as a result, to a loss of strength.

Ceramic and fireclay bricks It is resistant to weathering and temperature changes, so it is simply placed on pallets or platforms in the form of stacks with gaps to provide ventilation, and then covered with a tarpaulin or awning.

Sand-lime brick absorbs moisture, so it is protected from rain and snow under a canopy wrapped in plastic film.

Facing brick Protect from moisture and direct sunlight and store in a dry place.

Usually at the enterprise they are packaged in protective film and placed on pallets. After transportation, they are placed on a level area in stacks one on top of the other (no more than two). For long-term storage aerated concrete blocks, it is recommended to remove the lower part of the film around the perimeter for ventilation, and top part leave to protect from precipitation.

Here, the most important thing in conservation will be protection from water. Mineral wool is produced in the form of slabs or rolls in well-sealed polyethylene covers. However, when storing it for a long time, it is important to provide reliable shelter from rain and snow. The slabs are stacked one on top of the other in stacks no higher than 2 m, and the rolls are installed vertically in one row. Remember that walking on laid out soft mineral wool should not be used as it can be damaged.

To obtain high-quality and precise lumber products, they are stored in a dry, well-ventilated room at a temperature of 12-14 degrees. To make panels, formwork, and scaffolding, it is enough to protect the lumber with a canopy (cover) and leave it at the construction site. The boards are laid in layers on the beams (annual rings towards the top) and transverse spacers are installed to maintain a distance of at least 25 mm between the layers of boards, which allows for good ventilation, reducing warping and cracking of the wood.

Plasterboard is laid flat on wooden frame, under which a plastic film is laid. Layed sheets on top ( maximum height 1.2 meters) are also covered with another layer of film. To avoid deformation of the sheets, they should not hang from the frame.

Any developer, even a private owner, even construction company, we have to resolve the issue of safety of building materials. Now we will not touch upon issues related to the criminal talents of some individuals in terms of theft. Let us assume that our law enforcement agencies work for top level. Let's talk about how to properly store building materials to prevent damage.

The site is cleared of debris, all unnecessary objects are removed from its territory. It is necessary to provide for the possibility of accessing stacks of materials using small-scale mechanization, or at least a wheelbarrow. The entire area is compacted to prevent subsidence of the soil under the weight of the material.

As protection from precipitation, in the absence of a canopy, you can use ordinary roofing felt; it has proven itself just fine, especially since it is not that expensive.

All bulk materials can be divided into binders and those used as fillers.

Moldings and other lumber are stored in stacks. Storage of this type of building materials is carried out on an area treated with an antiseptic. The wood is sorted and placed on pallets to protect it  from ground moisture. The rows in the stacks must be separated by special spacers; they will ensure natural ventilation the entire stack. It would not be superfluous to treat the material itself with antiseptic solutions. When placing stacks, provide passages between them; remember, for safety reasons, the height of the stack should not be more than half its width. Round timber in stacks is reinforced with spacer posts to prevent rolling out. Before storing such wood, it is necessary to sand it, this will protect it from damage. To prevent cracking of the ends, a strip of bark no more than 10 cm is left at the cuts. The stack is covered with the same roofing felt, but not tightly, do not forget about the need for ventilation. For example, when tightly packed with polyethylene, timber can rot quite quickly, especially if it is poorly dried.

from ground moisture. The rows in the stacks must be separated by special spacers; they will ensure natural ventilation the entire stack. It would not be superfluous to treat the material itself with antiseptic solutions. When placing stacks, provide passages between them; remember, for safety reasons, the height of the stack should not be more than half its width. Round timber in stacks is reinforced with spacer posts to prevent rolling out. Before storing such wood, it is necessary to sand it, this will protect it from damage. To prevent cracking of the ends, a strip of bark no more than 10 cm is left at the cuts. The stack is covered with the same roofing felt, but not tightly, do not forget about the need for ventilation. For example, when tightly packed with polyethylene, timber can rot quite quickly, especially if it is poorly dried.

Storage of materials such as brick, slate, various blocks, recommended in indoors, V in exceptional cases under a canopy. The base of the stack is also raised above the ground. The material is stacked in stacks of up to 1.5 m; if the material has blind cavities, then it is laid down with them. Solid blocks and bricks can be stored without covering, but in the case of hollow materials with through holes, be sure to cover the stack. Otherwise, water frozen in them may tear the brick.

Precast concrete products are usually stored without shelter. They are stacked on top of each other, with obligatory separation by substrates. Exceptions are floor slabs. Since they are hollow, a cover is required, for the same reasons as for hollow bricks.

Compliance with all standards for storing building materials will allow you to save considerable amounts of money on construction. This will also help reduce transportation costs associated with the removal of spoiled material. We will talk about the rules for storing other types of building materials in the following articles.