Our company builds country houses more than 10 years. During this time, we have accumulated invaluable experience in frame house construction. We are fluent in technology and know how to quickly and efficiently build a warm and durable home for you.

We cooperate with several woodworking factories, where, according to our calculations, frames are made, truss structures, particle boards. Computer aided design All components are manufactured in our office using the time-tested MiTek program. The program not only produces structural drawings, but also calculates loads, which eliminates defects during construction.

It is important that the dacha be a place where you can relax with the whole family, enjoy comfort, celebrate the holidays and breathe deeply fresh air away from the city. At the same time, a country house should have all the components of a comfortable modern life. Nowadays, traditional construction from bricks and blocks is no longer relevant; this technology has been replaced by frame country houses. So, let's take a closer look at the features of this kind of structure:

On this positive features country houses frame houses do not end and this list can be continued for a long time. However, one should not think that it will be easy to build this kind of structure correctly; for this it is necessary not only to take an integrated approach, but also to have the necessary knowledge and tools. Therefore, it is better to entrust this activity to professionals to get the best result.

The first and main argument can be considered the cost-effectiveness of choosing this option. So, to build a country house, it will be necessary to spend more than half as much financial resources as compared to the construction of similar structures thermal insulation characteristics from brick base. Moreover, in country frame houses the costs of burning the premises are reduced, so you not only save directly on building materials and strength, but you also get savings in the future.

In addition, in the end, when the construction of a frame country house is completed, the result will be a house with ideal surfaces, free from curvature. They can be finished with any materials suitable for a particular case to make them look even more attractive. With help frame technology, you can create almost any architectural solutions, right up to implementation non-standard forms and the customer’s own sketches. Therefore, frame country houses will have as much space as the client needs.

Each of us has had to observe the devastation that occurs at a construction site; there is always not only construction waste left there, but also potholes, mountains of earth and other unaesthetic objects. When conventional construction, this horror cannot be avoided in any way, and yet, it is likely that you chose the place for construction precisely because of its landscape and nature. And then there is still a restoration process ahead, and this is also a costly business. What if country frame houses are created? Then all this simply will not happen - there will be no mountains of garbage, no potholes, no heaps of earth. And all because all the details are on construction site ready-made ones are delivered; this feature, among other things, significantly increases the speed of construction. It is in connection with all of the above that panel houses are increasingly being preferred over traditional materials.

There are several aspects due to which some people are afraid to invest money in the construction of frame country houses. Here are some of them:

Country frame houses will become the place where you will spend time with pleasure, and our company will help you create panel house your dreams.

More and more city dwellers are trying to escape from their stuffy apartments into nature, away from the noise of cars and smog. And for this purpose the dacha is most suitable. Relax, have a good time with friends or take care of your garden - a dacha is good for everything. A country house will save you from rain and cold, and outbuildings will ensure the safety of your equipment.

Frame houses are becoming increasingly popular. They are built quickly at minimal cost.

If you don’t have one, you can easily build a country house yourself. After all modern technologies allow you to do this quite quickly and quite economically. Country houses made of brick and cinder block are gradually becoming a thing of the past. The use of frame technology is suitable for this. You can build a frame country house with your own hands over the summer. And then the whole family can spend a vacation at the dacha next year. However, the dacha can be used not only for warm time years, but also as a full-fledged Vacation home. Therefore, country houses of frame technology are gradually gaining their adherents.

Any construction begins with a project. And country houses are no exception. The presence of a project helps to calculate the quantity necessary materials, as well as their range, which is very important for building a house with your own hands. Successful project will save not only money, but also minimize the remnants of materials used. Based on the project, you can determine the construction time and its cost. A frame country house must satisfy all the requirements of the owners, therefore, when creating a project, it is necessary to take into account the opinions of all family members. It is at the design stage that you can change any size of the future home. During the construction process this is, of course, possible, but it is associated with a number of problems.

Consider the necessary tools:

Frame houses are usually built one-story. A room under the roof can be used as a second floor.

Frame country houses are usually built with a height of 1 floor, and the roof design allows the room under the roof to be used as a 2nd floor. Frame construction involves the use of fairly lightweight materials: wooden blocks, OSB sheets, heat-insulating mats (or other insulation). Therefore, the construction of a very powerful and durable foundation is not required.

As a foundation you can use:

When choosing a method for laying a foundation, you should first of all take into account the characteristics of the soil on which the frame country house is being built. Most often, asbestos cement columns filled with concrete mortar are used.

For construction columnar foundation The following materials and tools will be required:

![]()

Before laying the foundation, markings of the future house are carried out. Using this marking, holes for the posts are drilled at a distance of approximately 80 cm. Asbestos-cement columns are installed strictly vertically along a plumb line, and the free space is carefully filled with sand, compacting tightly, but without disturbing the vertical. For better density when compacting, the sand is watered.

Next, concrete is poured into the pipes through a special funnel. Concrete is prepared from cement, sand and crushed stone in a ratio of 1:4:5. In this case, the concrete should not be thick and fill the space inside the asbestos-cement pipe. It is necessary to install plates on the foundation pipes, to which the logs will then be attached. After the concrete has completely hardened, construction of the house itself can begin.

It should be noted that the distance between the foundation columns may vary depending on the size of the materials used and the layout of the house. All this must be taken into account and calculated at the design stage.

Frame country houses can be built from various materials. But for self-construction wood is most often used. The beginning of the construction of the frame of the house begins with the floor. The bottom trim needs to be installed. To do this, the beams, the size of which are 150x150 mm, are placed on edge on the foundation columns. Several layers of roofing felt are first placed on top of the posts as waterproofing.

Using screws 100-120 mm long, the internal trim boards are connected to each other. 95 mm screws are used to fasten the middle board of the lower trim. After connecting all the boards of the bottom trim top part The boards must be leveled with an electric planer, checking the level for horizontal, diagonal, and corners. The lower trim must be made strictly according to the level; the slightest distortions will lead to a change in the geometry of the entire country house.

Next, using a jigsaw or saw, grooves are cut for the vertical posts in the corners and along the entire frame for further installation of the floor joists according to the design. The width between the joists is determined by the width of the heat-insulating mats that are used to insulate the floor. If a heavy stove or fireplace is to be installed in the room, then the logs in this place are placed at a shorter distance. Floor joists are placed in grooves and carefully secured to the foundation pillars and the bottom of the frame.

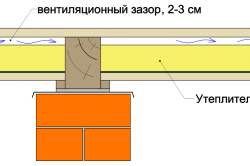

Next, 40x40 timber or boards for the subfloor are nailed across the lower parts of the joists. Sheets of plywood cut to size or sawn OSB sheets are laid between the joists on them. Secure with self-tapping screws. After this, a layer of waterproofing is laid, and then insulation. It is important to lay heat-insulating mats overlapping - this will make the floor even warmer. Next, the entire surface is covered with a vapor barrier film. Moreover, it needs to cover both the joists and the insulation. The film is attached with staples and a construction stapler to the joists, and the seams between the strips of vapor barrier film are taped. To ventilate the floor, a 40x10 board is laid on top of the vapor barrier. This ventilation gap will additional protection floors from rotting and thermal insulation. Next, the finishing floor is laid.

The material for it can be boards that are laid tightly together, which is achieved lock connection, or sheets of plywood at least 5 cm thick. Next, laminate, linoleum or parquet board. Logs and bars (boards) used for flooring must be treated with antiseptic compounds to extend their service life and avoid the appearance of rotting fungi.

After installing the floor, they begin to build the frame of the walls of the country house. Vertical posts are attached to the prepared grooves of the lower trim. The vertical is set strictly according to construction level and secure the racks with jibs. These additional bars are secured to the floor and stud with nails. Subsequently, after completion of the construction of the 1st floor, these jibs are dismantled. The longitudinal jumpers can be 40x40 mm timber, which is attached according to the groove-to-groove principle and secured with nails. After fixing all the jumpers, you can sheathe the outer walls OSB boards or sheets of plywood. Only door and window openings are left. The top strapping can be the same beam used to install the bottom one, which also fits into the grooves.

After the frame of the 1st floor is ready, it is necessary to begin construction of the roof. On top harness laid, which are secured with short jibs. The distance between the beams is 60 cm. Next, a raw board is filled downwards across the beams. OSB or plywood sheets are attached on top of this board, which will serve as the ceiling. Insulation is placed in the space between the beams.

You can use mineral wool sheets, expanded clay, thermal insulation mats. After laying the insulation, the entire surface is covered with a vapor barrier film and OSB sheets or plywood are stuffed on top.

Rafters are attached to the beams. In this case, the lower ends of the rafters should protrude beyond the borders of the house at a distance of 50 cm. For additional fastening of the rafters, short slopes are used, one end of which is nailed to the rafters and the other to the beams. This will give the structure rigidity. The distance between the rafters is no more than 60 cm.

Having secured the rafters from above, you can form the ridge part of the roof. Next, fill the sheathing with untreated boards. The boards can be laid tightly one to the other or at a short distance. For waterproofing, a layer of roofing felt is placed on top of the boards - the very simple material. Laying is done vertically overlapping using nails with a wide head.

It is advisable to coat the seams with a special mastic.

To enhance waterproofing, you can lay a second layer of roofing felt, positioning it perpendicular to the first. Next you should lay roofing material, For example, roofing sheeting, flexible tiles, metal tiles. Whatever the material is chosen, it should be fastened very carefully to avoid disruption by gusts of wind.

If a frame country house is planned without an attic and this room will be residential, then insulation and vapor barrier are laid between the rafters, everything is covered with OSB boards or plywood, as is done throughout the house.

After installing the frame and roof, you can begin cladding the outer walls. To do this, you can use OSB boards for external walls or thick sheets of plywood. They are attached to the posts using self-tapping screws and a screwdriver. Next, you should insulate the walls.

The process of insulating walls is no different from that which was performed during the construction of the floor, except that a ventilation gap is usually not created. The ends of the roof are also covered with OSB boards. The house was built with my own hands. Only the external and interior decoration. Good luck!

Frame cottages for summer cottages are gaining more and more popularity around the world.

They are built very quickly, and they can not be placed anywhere on the site using a lightweight one.

garden house may become the first building on the territory, to which you can then add a bathhouse, guest housing, etc.

A properly built house will be cozy and beautiful.

From the looks of it small building, inside which there can be a kitchen, a bathroom and a bedroom.

If the house is additionally insulated, then you can live in it all year round(heating must be taken into account).

It is very important that a country house be as comfortable as possible for each family member, which is why during construction you need to think through all the aspects of its arrangement.

The best material for the building is.

Do-it-yourself frame houses for a summer residence are very easy to build.

The first thing you need to decide is the location on the site and the size of the house, creating a project and planning actions.

The foundation is the basis of any building, so construction always begins with its construction.

It must be remembered that frame house is very light, which means there is no need to pour a durable, expensive base underneath it.

In most cases, columnar is used.

After the area has been marked and measured, the construction of the foundation can begin. The shape of the columns is not important.

A strip foundation can be the basis, but its construction will require more resources and time. You will need to dig a trench along the entire perimeter of the territory, waterproof it, install reinforcement, create formwork and pour concrete mixture. And then it will take about a month for the structure to harden and dry completely. However, many developers still choose a strip foundation because it allows them to build.

Attention! If the ground at the construction site is not stable (slopes, landslide zone, swamp, etc.), then a strong cushion must be created at the base of the pillars. It is made of compacted sand and a small layer concrete mixture. If necessary (for example, when building a 2-story building), you can strengthen the foundation with metal rods.

For an ordinary building, a column diameter of 300-400 millimeters is enough. They are driven into the ground or installed on a solid base on the surface. The posts are mounted in the corners, then at a distance of 2 to 3 meters.

After constructing the foundation, you can proceed to laying out the rough base of the floor. First, beams are mounted along the perimeter of all pillars, then transverse beams are placed on opposite parts. The result should be a floor on which lies the primary floor and the house itself. The material can be any:

The choice depends on the budget. It is important to connect the planes of the pillars correctly and tightly.

The walls are made of metal or wood.

Usually the choice depends on the availability of material and the construction budget.

For regular 1 storey building enough wooden beams(100 mm section).

Metal racks are stronger (section 50mm), they are able to withstand greater loads and remove weight from the foundation.

The racks are placed in the corners, then the distance ranges from two to three meters. The cross members must be made of the same material with a similar cross-section. They are installed staggered, at a distance of 1.5 (one above the other).

The openings between the windows are trimmed with crossbars on both sides (top and bottom). In the case of doors, only the top fasteners are enough. The dimensions between the structures must match the dimensions of future windows and doors.

If planned two-storey house, then you need to decide on the point of access to the 2nd level at this step. The entrance should be finished with beams.

It is important that the roof frame is light, but at the same time durable. The best option will use wooden materials. The most simple design – pitched roof. However, if you plan living room in the attic, you will need a gable structure. The height of the roof ridge will depend on the desired dimensions.

It is noteworthy that installing a roof frame requires more strength and skill than installing walls.

First, you will need to build in racks along the ends of the house and place spacers at the angle of the roof slope.

Then on to this design.

A beam is mounted along the entire length of the building, which will be the outer half of the frame. She serves as the ridge of the house. Next you need to create roof slopes on all sides.

The boards cling to the ridge and to the outer perimeter of the ceiling structure. The opening is from 0.5 to 1 meter. The pitched boards are attached in a checkerboard style using cross bars. At this point you can finish creating the building frame.

The material for the roof is selected before arranging the frame.

The fact is that the rafters and cross sections in the roofing part are adjusted to the chosen one.

Typically, manufacturers indicate the characteristics and requirements of the product for the frame.

For convenience, when purchasing material, you can purchase an installation diagram.

In the inner part, the roofing material must be insulated using roll insulation.

The next stage is installation window system and doors. Frame cottages for summer cottages can be built inexpensively yourself without much effort

In the role of external and internal lining can be used different materials. You need to focus on personal preferences and construction budget. The main thing is that the selected materials are resistant to external influences.

Construction process frame house simple The work can be greatly simplified with the help of a pre-drawn drawing of the future. It is recommended that along with the construction materials, you purchase documentation that specifies the parameters and installation rules.

How to build frame dacha on your own - on video:

Noticed a mistake? Select it and click Ctrl+Enter to let us know.

A dacha without a house is not a dacha at all, but an ordinary vegetable garden, where it is even impossible to really relax. Good if available small garden, in the shade of trees where you can comfortably sit on the grass. Yes, yes, yes modern man The requirements for a dacha are somewhat different than those of our parents - it serves more as a recreation area than as a help to the family income. In general, there must be a house in the country, and one way or another, it will have to be built. Exactly how to build a frame country house with our own hands, we will discuss this article, in which, together with the website, we will study in detail this technology for building houses.

How to build a frame country house with your own hands

Any construction begins with the foundation of the house, because everyone knows that a strong and reliable foundation is the key to long years of service for the house. It is for this reason that at this stage construction must be handled with full responsibility. Moreover, the requirements for the foundation for buildings of this type are not so high. A frame structure is a lightweight structure, and the foundation for it is built shallow. The maximum is slab, and even then it will be too much. If we consider the technology for constructing a foundation for a frame house, it can be represented as next sequence performance of work.

The foundation of a country house using frame technology can be poured a little differently - quite often the trench is filled with crushed stone and rubble stone, after which it is spilled with a liquid solution. In principle, such a foundation is quite suitable for light buildings. About frame technology country house construction can be seen in this video.

There are two technologies frame construction houses - this is directly frame technology and frame-panel method. Let's consider both options for building such houses and start with a simple frame technique, which can be represented as the following sequence of work.

Frame-panel technology is somewhat similar to that described above and differs from it only in that the walls are assembled completely at the bottom. In a lying position, a frame is made so that in ready-made version it could be easily installed in a vertical position. Immediately on the ground it is sheathed with OSB and insulated from the inside mineral wool. For electrical wiring, pipes or corrugations are placed in such shields. Subsequently, the frames are installed on the foundation and connected into a single solid array.

Frame and panel country house photo

This technology has one small drawback, and some people may find it significant. The size of each individual shield will have to be calculated - not only that, you also need to take into account, or rather, think through the way of connecting the shields to each other. As a rule, the panels are given some semblance of a tongue-and-groove board - on one side, the outermost vertical beam is pushed outward by half its thickness, and on the other, on the contrary, it is pushed inward. Subsequently, they are screwed together with self-tapping screws through the OSB - as an additional fastening, powerful steel plates are installed in the upper part of the shields or, again, a beam is inserted, having previously provided a place for it.

In all other respects, a frame-panel country house is not much different from an ordinary one frame structure.

There are not very many main points that can affect the quality and duration of operation of a given frame house, but failure to comply with them may result in some unpleasant consequences, which can affect the technical and operational characteristics of the structure. These points include the following nuances.

In principle, there are no other serious issues that could affect the service life of this frame structure.

There are other ways to build a frame country house with your own hands. In principle, the technology remains the same, but only the material used changes. For example, the frame can be welded from a corner or channel, and the outside can be sheathed with corrugated sheets or other similar materials. In general, there are many options, and the most interesting thing is that you can use almost everything that is somehow suitable for these purposes. If you want to bring beauty, then use good material, and if beauty is not important, then any material will do.