In a private house, the sewage system consists of a cesspool and special PVC pipes connected to it. Autonomous system equip country cottages, as well as city houses located outside the centralized zone sewer network. But if earlier the pit was laid out of bricks or blocks, now, thanks to modern technologies, the process is greatly simplified. Nowadays, an autonomous sewage system is a well made up of ready-made concrete rings. Before you buy similar products, it is worth familiarizing yourself with their types, dimensional parameters and installation method in more detail.

Reinforced concrete ring elements have a number of advantages:

1. long service life without scheduled repairs - it is achieved thanks to the strength of the structure, created from concrete and a frame made of steel rods;

2. suitability for any type of soil - reinforced material is designed to withstand the pressure generated by the movement of groundwater or soil displacement;

3. high installation rates;

4. ease of arrangement of a well of any depth;

5. ensuring high-quality waterproofing;

6. the ability to quickly and effectively clean;

7. resistance of the material to aggressive environments.

One of the few disadvantages of reinforced concrete products is their massiveness. To arrange drain hole For small house or cottages, they usually use rings that weigh 0.6-1.1 tons. Therefore, their installation without a lifting mechanism is very problematic, as is the entry of equipment into a landscaped garden plot.

Products are made from heavy reinforced concrete(from B25 and above), their frost resistance is at least 100 cycles (F100). An important indicator is the degree of waterproofness. They must be made of a material that can withstand water pressure of at least 4 kg/cm2 - in the designation of concrete this is marked with the index W4.

The design of a reinforced concrete element for sewerage depends on its purpose. According to GOST 23009, the following types of products are produced:

If it is not possible to install a well of the required depth, then additional products are used, the dimensions of which differ from the standard ones.

Ring sizes range from 840 to 2200 mm ( outside diameter). Each diameter corresponds to 2-3 options for wall thickness (from 70 to 100 mm) and height (from 290 to 890). Typically, home sewerage is equipped with wall KS 15 (D 1500 mm) or KS 20 (D 2000). average cost ranges from 2500 to 5500 rubles. The price of options with a cover (D 1160 mm) is on average 3000, and the cost of a floor slab is 2500-5000. Options with a bottom are sold for 5500-9500 rubles.

IN Lately they began to produce Euro-locking rings with special openings and ridges. The lock ensures ease of assembly and tightness of the mounted structure, even and smooth walls of the concrete well - thanks to this, the sewage system is better cleaned. The cost of a locking ring is approximately 20% higher than the price of a regular one of the same diameter.

Step-by-step installation instructions

The sewerage system is installed in several stages, the most labor-intensive of which is excavation work.

1. Digging a hole. Sometimes the soil is manually undermined evenly along the contour of the ring, which is gradually lowered to its entire height. Place the next concrete element on top and continue to undermine the soil. The second method is preliminary digging of a pit manually or using construction equipment. The dimensions of the pit must exceed the diameter of the ring by 0.4 m, and the total height concrete products– by 0.2-0.3.

2. Arrangement of a sand cushion. The bottom of the pit is leveled and compacted, coarse sand is added, moistened and compacted.

3. Concreting the bottom. Instead, another scheme is used. You can first install a product with a bottom - despite its relatively high cost, it is economically feasible. If you didn’t buy rings with a bottom, then the base is concreted yourself. First, pieces of brick or concrete blocks are laid, on which the reinforcement is placed in the form of a lattice.

A solution of 1 part cement (preferably M400 brand), 3 hours of crushed stone, 2 hours of sand and 0.5 hours of water is poured over the frame. Must be prepared immediately required quantity concrete so that the pouring is one-time, without additional mixing. Thanks to this, the system will be more durable and airtight.

4. Installation of ring elements. The concrete ring for sewerage is equipped with special mounting loops (ears), to which the slings of the lifting device are attached. Lift the product by all four ears so that the cables are evenly tensioned. The bottom one is set according to the level, then the rest are lowered one by one.

The structure being constructed is simultaneously sealed. The joints are treated with a cement-based sealant, the outer and inner cylindrical surfaces are covered with hot bitumen or another waterproofing agent.

5. Installing the cover. The gap between it and the top element should be carefully sealed. At the end of installation, the cover and the gap between the walls of the pit and the rings are filled with soil.

It should be noted that recently, instead of a traditional cesspool, sewage systems are increasingly being installed in the form of a septic tank - a system of wells in which sequential fermentation, purification and filtration of wastewater occurs. This option eliminates the need for the homeowner to use the services of a vacuum cleaner. The cost of a turnkey septic tank is 30,000-35,000 rubles.

It would seem that the construction of a septic tank on suburban area ceased to be big problem associated with a considerable amount of work being carried out. After all, accessibility plastic containers, specially produced for the sewer system, transferred this type of structure to the group with the lowest costs. But life shows that concrete rings for sewerage are still in demand. What's the matter?

Like all Construction Materials, reinforced concrete sewer rings have positive characteristics and negative. Let's start with the advantages:

The disadvantages include the difficulty of carrying out installation work. It is impossible to assemble the rings by hand, their mass is too high. Therefore, to install products in a prepared pit you will need crane, whose services will have to be paid.

The same applies to unloading. It is prohibited to roll rings around the territory; they may simply become unusable. Therefore, to the site where the septic tank is assembled, it will be necessary to organize an access road for a vehicle transporting reinforced concrete products. In addition, the installation site of the septic tank must be as free as possible so that the crane boom can work.

As for classification, manufacturers today offer two types of concrete rings for sewerage:

The first class includes products whose annular planes (ends) are flat. The second class includes products with rebated protrusions. The protrusion is internal at the top and external at the bottom.

The quality of the second option is obvious. By installing one ring on another, a seal is created lock connection, moreover, the strength of the joint is several times higher when compared with a flat connection. But in any case, the joining of two elements is done using cement mortar.

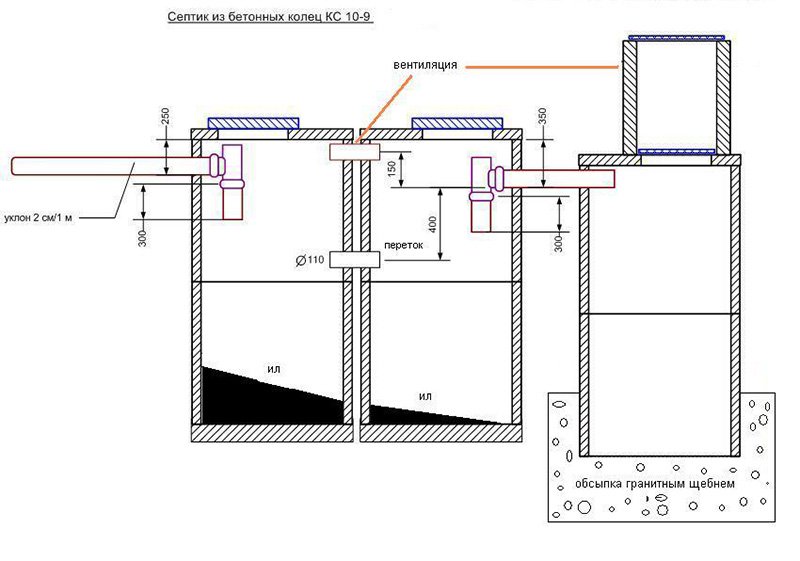

In the notation reinforced concrete rings There are both alphabetic and numeric characters. For example, brand KS 10-9. By the way, this is the most popular ring that summer residents use to organize the collection of sewage.

So, KS is a wall ring, 10 is the internal diameter, 9 is the height. All digital designations are used in decimeters. Currently, manufacturers offer a fairly wide range of both diameter and height. The table below shows all the characteristics of reinforced concrete rings.

| Product brand | Inner diameter – outer diameter – height, mm | Volume, m³ | Weight, kg |

| KS 7-3 | 700×800x290 | 0,115 | 130 |

| KS 7-6 | 700×840x590 | 0,23 | 250 |

| KS 7-9 | 700×840x890 | 0,35 | 380 |

| KS 10-3 | 1000×1160x290 | 0,24 | 200 |

| KS 10-6 | 1000×1160x590 | 0,47 | 400 |

| KS 10-9 | 1000×1160x890 | 0,7 | 600 |

| KS 15-3 | 1500×1680x290 | 0,53 | 290 |

| KS 15-6 | 1500×1680x590 | 1,06 | 660 |

| KS 15-9 | 1500×1680x890 | 1,58 | 1000 |

| KS 20-6 | 2000×2200x590 | 1,88 | 980 |

| KS 20-9 | 2000×2200x890 | 2,8 | 1480 |

Before proceeding with the construction of a sewer collector, it is necessary to make a preliminary calculation. There are certain requirements and standards by which the sewer system is calculated for country house. For this there is a formula in which three indicators are multiplied together:

Eg, small house, where a family of four lives. The volume of the septic tank is 0.2×3x4=2.4 m³. Round up to 2.5 m³. We look at the table and select the rings. There are many options. You can install 4 rings KS 10-9, one KS 20-9, seven KS 7-9 and so on.

Of course, the main question that worries many consumers is how much it costs to construct sewer systems. There are no fixed cost indicators; you can only average them. Let's group several items into a table taking into account VAT.

| Brand | price, rub. |

| KS 7-9 | 1750 |

| KS 10-9 | 2000 |

| KS 15-9 | 3000 |

| KS 20-9 | 6500 |

You can also carry out comparative analysis by price, comparing concrete sewer rings and a plastic septic tank. For example, the “Economy T-1300N” model with a volume of 1.2 m³, which costs 22,500 rubles. In order to assemble a septic tank from rings of this volume, you will need two rings of the KS 10-9 brand, which in general will cost only 1,200 rubles. Add in the services of a crane, and it will still be several times cheaper.

Like anyone construction process, the construction of a prefabricated sewer well consists of several stages.

Depending on what products were chosen for the septic tank, you need to dig a hole for them; you can do this yourself.

The dimensions of the pit, especially its width, should be larger than the diameter of the rings.

The bottom of the pit is leveled and covered with a layer of coarse sand or fine crushed stone. The layer thickness is 20 cm. This pillow must be compacted and leveled horizontally.

Then a metal reinforcing frame made of 10-12 mm reinforcement is installed. The lattice should be placed not on the pillow itself, but on stands so that the frame is in the body concrete mortar. Pieces of brick can be used as stands.

Concrete is poured and leveled. In this condition, the bottom of the septic tank should remain for 28 days. In order not to wait so long, you can purchase concrete rings with a finished bottom, designed for sewer construction. This simplifies the process and speeds it up, plus it saves money. The finished bottom (this is a round reinforced slab) is placed on the cushion using a crane.

Please note that models with a bottom come in two types: solid and perforated (with holes). The first are used for wells that are used as cesspools. They can also be installed in a first-level well system. The latter are installed in second-level septic tanks.

Now all that remains is to install the concrete rings for the sewerage on top of each other. If elements with a bottom are used, then a small layer of cement-sand mortar is applied around the perimeter of the laid slab. The ring is lowered and leveled in planes.

A layer of fastening mixture is applied to its upper end. A second product is installed, which is also leveled in planes. And in this way the entire well is assembled.

The outer surfaces of the well are treated with either hot bitumen or bitumen waterproofing mastic. WITH inside the joints of the rings are treated with resin or hot bitumen. Some craftsmen close the joint between the rings and the bottom with a clay lock.

![]()

And the final touch is installing the finished lid, ventilation pipe and filling the gap between the walls of the pit and the well with soil.

First of all, you will need to make the formwork. Don’t listen to anyone and remember that formwork is made only from steel sheets with a thickness of at least 3 mm. Rings with different diameters are made from sheets, which are inserted into each other. All formwork elements are detachable and connected with bolts.

Is a reinforcing frame really necessary? It is not necessary to use it. But for this you will have to increase the wall thickness of the product by approximately 30%. For example, the wall thickness of the KS 10-9 ring is almost 12 cm. This means that it is necessary to increase the size to 16 cm.

As a reinforcing frame, you can use plaster metal mesh, laid in two rows. The meshes are usually connected to each other with knitting wire.

Concrete mortar is made on the basis of cement of a grade not lower than M400. In addition to this material, it is necessary to use sand and gravel. To produce the solution, a classic recipe is used:

The formwork is being assembled. The two rings are temporarily fastened together by rigid ribs (they are in the form of a hook) located along the perimeter. Two or three spacers from metal profile. A reinforced frame is installed in the gap between the formwork elements. Concrete is poured and compacted with a vibrator.

After four days, the formwork can be removed. And after 15-20 days, self-made concrete rings for sewerage installation can be installed at their destination.

Sewerage in country house– part of the condition comfortable life, and it must work continuously and smoothly. To do this, if there are no options for connecting the drain to the central sewer system, organize an autonomous industrial or homemade septic tank. The septic tank can be anything - concrete, plastic, brick or metal, but the most convenient and quickly erected design is a container made of reinforced concrete rings. Let us consider in more detail what dimensions of concrete rings for sewerage are required and how to make such a septic tank.

Concrete rings are made from high-quality Portland cement M 400-M 500. positive aspects We note the following products:

Negative points:

Most often in individual construction rings of different sizes made of concrete are used to create autonomous private sewer or when installing drinking wells. Rings with a special lock on the ends are best suited for installation - connecting the protrusions on one ring with grooves on the other makes the structure more stable, durable and immovable, allowing you to maintain the required tightness of the tank under any operating conditions. Such rings are called folded, and rings without locks are called solid. In addition to the seam rings, lids, bottoms and hatches can be made - especially for cases when a drinking well or sewer system is made from concrete rings with your own hands.

When making rings with a locking mechanism, fine-grained concrete is used, reinforced with reinforcement, which extends the service life of the product and increases the rigidity of the structure. In addition, reinforcement solves the following problems:

Concrete rings for sewer wells are marked with the symbols “KS” - wall ring - and numbers indicating the internal diameter of the concrete ring and the height of the ring. These values are expressed in centimeters. Zeros after integers are not written on the markings. For example: KS10-9N - wall ring, internal diameter 100 cm, ring height - 90 cm, the symbol "N" indicates the permeability coefficient (N - normal permeability).

Dimensions of concrete rings for homemade autonomous septic tank, are selected based on the sewerage system design data - size sewer well, type of well (filtration, waste, drinking, drainage, flushing, differential or inspection) and other indicators. Ring markings also include the designation of volume, ring weight, and. To decipher the markings, there are special tables ( reference Information), and a fragment of one of them is given below:

| Marking | Ring sizes in cm | Internal volume, m 3 | Weight, kg | Brand and class of concrete, M|B | ||

| Length | Width | Height | ||||

| KC 7-3 | 70 | 80 | 29 | 0,05 | 0,13 | 200|15 |

| KC 7-6 | 70 | 84 | 59 | 0,10 | 0,25 | 200|15 |

| KC 7-9 | 70 | 84 | 89 | 0,15 | 0,38 | 200|15 |

| KC 10-3 | 100 | 116 | 29 | 0,08 | 0,2 | 200|15 |

| KC 10-6 | 100 | 116 | 59 | 0,160 | 0,4 | 200|15 |

| KC 10-9 | 100 | 116 | 89 | 0,24 | 0,6 | 200|15 |

| KC 15-3 | 150 | 163 | 29 | 0,13 | 0,29 | 200|15 |

| KC 15-6 | 150 | 168 | 59 | 0,27 | 0,66 | 200|15 |

| KC 15-9 | 150 | 163 | 89 | 0,40 | 1,0 | 200|15 |

| KC 20-6 | 200 | 220 | 59 | 0,39 | 0,98 | 200|15 |

| KC 20-9 | 200 | 220 | 89 | 0,59 | 1,48 | 200|15 |

You can proceed not only from design information, but do the opposite: having at your disposal reinforced concrete rings of a certain brand, plan how to make a sewerage system according to one or another scheme, since you can immediately solve problems such as the use of the type of special equipment, transportation, tank volume septic tank, the presence of future drainage fields, etc. The dimensions of concrete rings are established in GOST 8020-90. Knowing the dimensions will be useful if installing entire rings does not cover the entire height of the well. In this case, the well is completed with additional rings that are smaller in height.

In addition to additional ones, rings with a solid bottom are made. Such products will serve for a long time in septic tanks where the tank is cleaned by pumping out wastewater with a pump, as well as in sewer settling wells or during the construction of a septic tank with a settling chamber. In such rings, concrete of lower grades is used - M 200-250. The advantages of rings with a bottom are obvious: there is no need to seal joints, there is no need to apply additional waterproofing, and the volume of transport and installation work is reduced. To the listed advantages you can add the ability to order ring diameters based on individual measurements.

Standard diameters of concrete rings with a solid bottom:

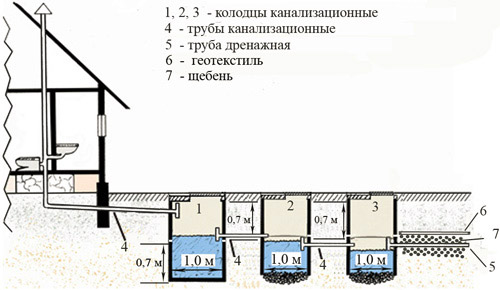

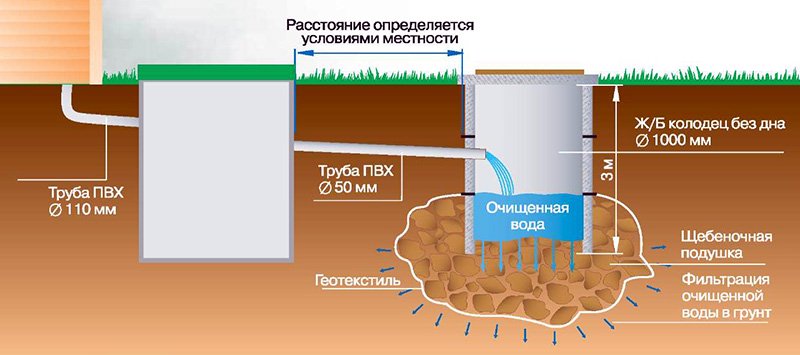

The installation of rings is preceded by drawing up a project, carrying out calculations, the number and brand of rings, and determining the type of sewerage system. Standard option sewerage with a septic tank for a country house or a small country house - one septic tank of three rings, the lower ring with a solid bottom, the upper one with a hatch. Autonomous sewerage made of concrete rings, the diagram of which is given below, will work quite reliably and efficiently at any time of the year:

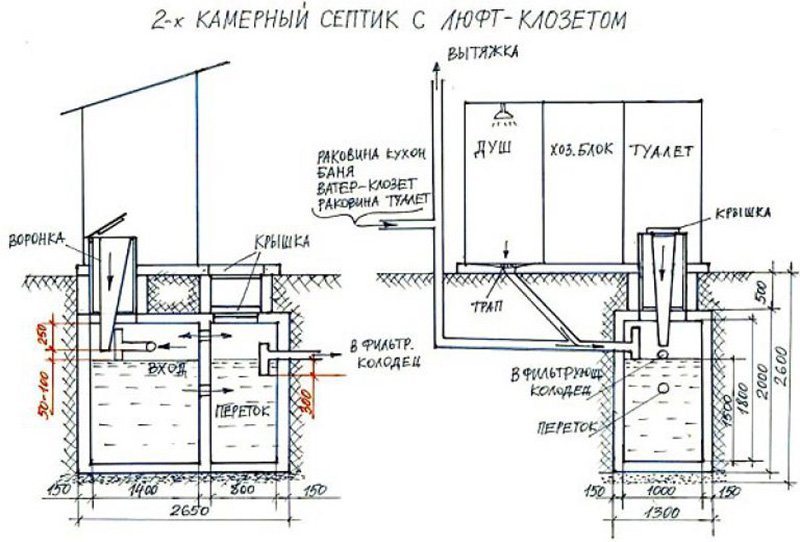

The volume of the septic tank is calculated according to the number of people living - in a house for a family of 3 people you will need a septic tank with a volume of up to 2 m 3, since the average daily water consumption for one resident is approximately 150-200 liters. Also, the number of septic tank chambers, that is, the number of concrete rings, also depends on the number of permanent residents. Yes, for large family equipment is required for at least a two-chamber septic tank, which means that rings may be needed different sizes and volume.

An autonomous private sewerage system built using concrete rings is implemented according to different schemes and with a different set of products. The choice of scheme depends on many factors and conditions. Here is the topography of the site, the number of residents in the house, the properties of the soil, and other calculated and reference parameters.

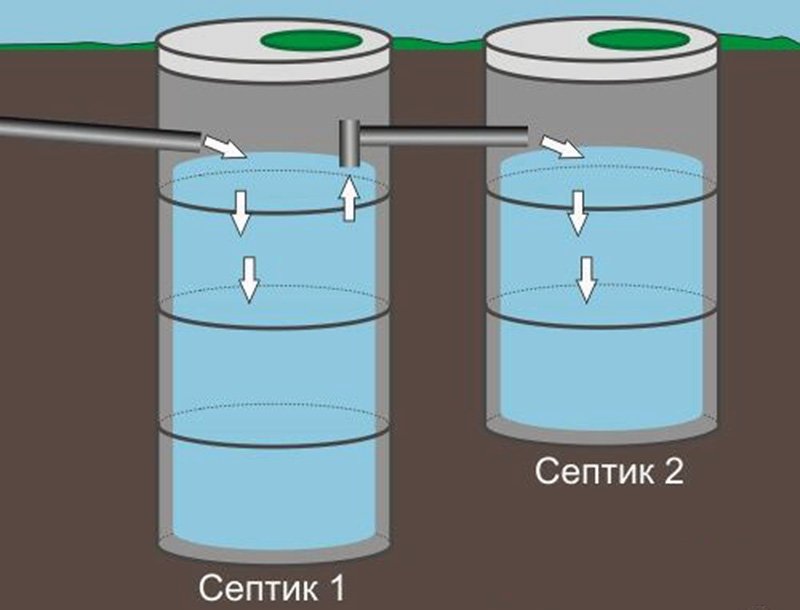

If we are installing a sewer system that will work constantly and around the clock for a family of 3 people, then a septic tank made of rings with two chambers will be the optimal solution to the problem of disposing of the entire volume of wastewater. For example, this is a scheme that uses two tanks, each of which is made of three concrete rings, where the lower ring has a bottom and the upper ring has a hatch:

The sketch shows that the circuit is the simplest, but, nevertheless, working and reliable. The greater difficulty here is connecting the input and output, arranging ventilation, organizing hydro- and thermal insulation, maintaining the slope of sewer pipes, and much more.

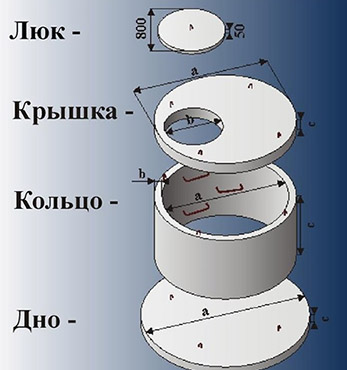

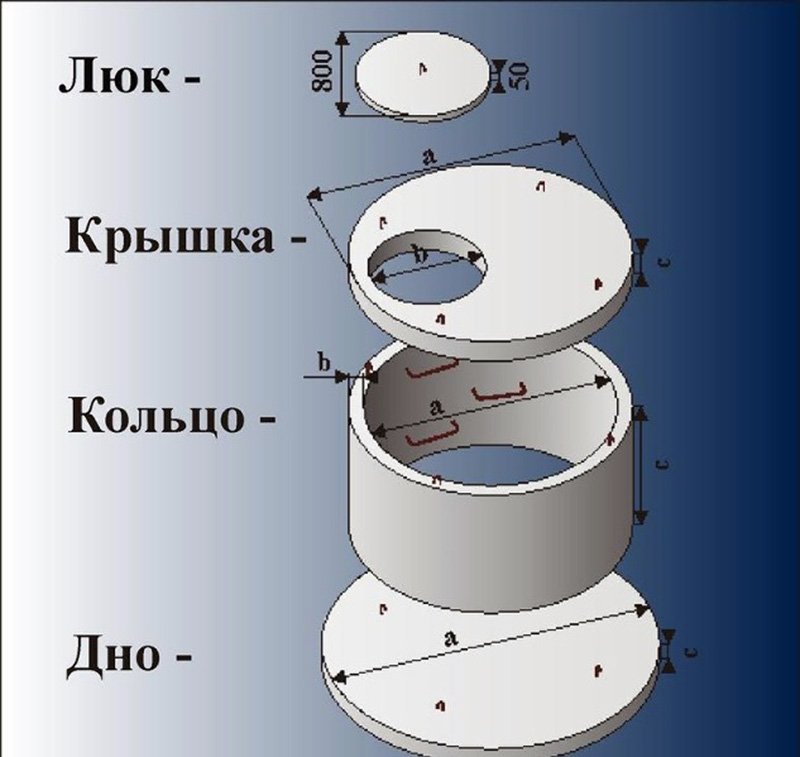

The main components and parts of a well made of reinforced concrete pipes:

In order to purify wastewater as much as possible, the work of bacteria and settling of contaminated water alone is not enough - you need to equip filtration fields, and the beginning of such purification also lies in the construction of a filtration well, the water from which will be drained into the filtration fields. Such water can not only be drained into reservoirs without the risk of polluting them, but also used for watering a garden plot or for technical needs.

Two-chamber sewer septic tank or cesspool of two reinforced concrete wells does not require the completion of filtration fields or wells - the septic tank can handle this amount of work itself, because the second well is intended specifically for the additional treatment of sewage wastewater.

The design of a two-chamber waste septic tank made of concrete rings is more complex and more expensive than construction a septic tank or storage well according to a single-chamber scheme, since in this option both rings with a bottom and rings with a neck and holes for sewerage inlet/outlet will be used. To reduce project cost and construction work It is recommended to use rings with locks - this will allow you to get rid of additional waterproofing, arranging a sand cushion and sealing joints.

The first concrete well in two-chamber septic tank it is built from 2-3 rings with locks - this depends on the depth of the well, which, in turn, depends on the properties of the soil. The primary chamber is dirty waste water will settle for some time - large solid sediments will fall to the bottom, and the clarified wastewater, after flowing along the accumulation boundary, will enter the secondary chamber, where it will be finally purified and removed outside the site or pumped out for the needs of the farm.

The secondary tank is erected by the same installation of concrete rings on top of each other, ensuring that the locks match. Microorganisms can be added to the second tank to accelerate the decomposition and processing of wastewater. In this case, the sludge settles to the bottom, and the clarified water is discharged into the soil or out.

Dimensions of concrete rings for sewerage updated: April 16, 2017 by: kranch0