You can build a Russian bathhouse with your own hands from start to finish, install windows and doors yourself, install a wooden font and furniture assembled with your own hands. But first you need to properly raise the frame, lay the floor, sew up the ceiling, and build a stove. Studying step by step instructions and advice from professionals will help with this.

The human body temperature does not exceed 40° because he sweats, due to which he releases excess heat into the surrounding air with the release of excess fluid. This is the basis of the operating principle of any type of bath. The differences are only in the ratio of temperature and humidity.

In a Turkish bath (hammam), the humidity reaches 100%, and the temperature of the air, stone floor and benches does not exceed 40°. In sauna ( Finnish sauna) this relationship is completely opposite. At 120° the humidity is only 40%.

But the optimal combination of temperature and humidity for health (and there will be no negative consequences from such a procedure) can only be maintained in a Russian bathhouse, but only if it is properly designed and built.

A bathhouse cannot be called a cheap pleasure. If you order its construction on a turnkey basis, the amount may turn out to be unaffordable. With average prices for materials and specialist work, you will have to pay from 7 to 22 thousand dollars. Most simple bath You can build it yourself, saving significant money.

Russian baths, as close as possible to traditional ones, are coming back into fashion. They have their own characteristics:

All this creates a lot of unnecessary difficulties; the bathhouse itself is generally flammable and short-lived. But there is every opportunity to independently build a bathhouse with the same qualities, but much more practical and modern. It is recommended to make a sauna house not only with a steam room, but also with a washing room, where there is a font, a tub for dousing or a shower, and a dressing room.

They undress in it, store towels, sheets, brooms and brooms, relax between visits to the steam room, and drink tea. This room serves as a barrier to cold air. There is a window there (for security reasons and for beauty).

A heater with a water tank is installed in it, and beds or shelves for lying on are built. The oven provides uniform, strong heating and exposure to superheated steam without convective air mixing.

Washing

Preparing for construction

Selecting a location

If the area is small, then you don’t have much choice. But if it is spacious, then there is an opportunity to use all possible advantages.

Selecting wall material Although a bathhouse can now be built from anything, for example, from brick, polystyrene concrete, aerated concrete, expanded clay or foam blocks, there are physical laws that confirm the appropriateness of the conservative practices of our ancestors. And all due to the fact that it heats up very much and then cools down, it creates, and after ventilation the rooms dry quickly. Blocks and bricks in this mode must have a special multi-layer cladding.

The tree may not have any cladding. In addition, it is this material that, when heated, gives an exceptionally healthy and beneficial heat. Therefore, for aesthetic and practical reasons, it is recommended to dwell on it.

The intensity of the steam depends on the wood from which the walls of the steam room are made:

What you need to pay attention to when buying wood:

Glued imitations are suitable for any building, except for a bathhouse. The lamellas from which the timber (or log) is made warp and deform due to temperature.

Solid timber can be profiled or regular edged. The main disadvantage of the second type is frequent warping as a result air drying. Profiled timber is expensive, and not just any one is suitable for building a bathhouse; for example, material with recesses at the top is not suitable due to the collection of condensate in them.

Therefore, most often a log is used to build a bathhouse. Raw or wild is difficult to buy. Therefore, it is recommended to choose a rounded log: it is well dried and smooth. It should not have radial cracks, as condensation accumulates in them, and this leads to rotting. Likewise, it should not have cuts in the upper part. To cut into a bowl, the log must have a so-called moon groove at the bottom.

You need to choose the cutting method in advance. There are several options for designing the ends of the logs and assembling them into a structure:

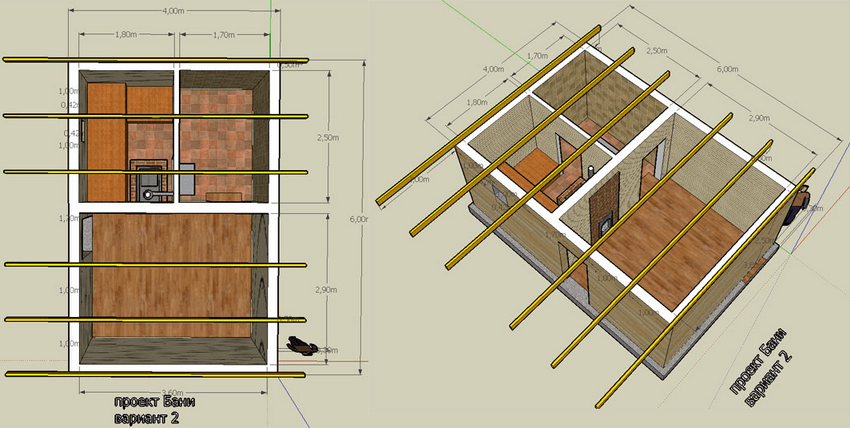

Since the length of a rounded log is 6 meters, it would be logical to take this into account when designing a bathhouse, making its side exactly like this. The building must have a steam room, a washing room, a dressing room and a stove. The height of the bath is usually determined solely by capabilities, but traditionally the floor to ceiling should be 220 or 230 cm.

This is a key step. Without approval of the project before the start of construction, an already built bathhouse can be demolished due to any complaints from neighbors, and you will lose the labor and money invested.

Approximate material calculation

To carry out the calculation, you need to take into account what diameter the log will have. A larger one is better for a bath, but it is more expensive. The optimal diameter is 280 mm. The cost of 1 m 3 of such logs with cups is on average about 8 thousand rubles. Now you need to determine the height of the pediment. To do this, it is recommended to focus on natural conditions . If there is a lot of precipitation, the gable should be high and the roof should be steep so that the snow doesn’t stay on it badly, and when strong winds

The average height of the pediment is 1.5 m.

The average height of the pediment is 1.5 m.  Photo gallery: drawings of a log house and necessary parameters

Photo gallery: drawings of a log house and necessary parameters  Top view and log cross-section parameters

Top view and log cross-section parameters  A drawing of a log house will help in filling out the initial data

A drawing of a log house will help in filling out the initial data  To calculate the amount of material, you must fill in all the initial data

To calculate the amount of material, you must fill in all the initial data

All values can be entered into a special table

construction trestles;

Now you can proceed directly to construction.

All work can be divided into stages that follow each other. Between some of them it is necessary to make a certain time interval.

All types of foundations, except boulder foundations, require waterproofing between. It is usually done using roofing felt or bitumen.

Lathing with thin slats over waterproofing is needed to prevent capillary seepage of moisture into the frame. However, a columnar block foundation does not need it.

This stage occurs immediately after the foundation is laid, before the construction of the log house, simultaneously with the insulation of the subfloor.

In the old baths, the drain went straight through the plank floor to the ground, so the building was placed on a natural slope. Now such a drain is prohibited, but you can use the idea itself both in the steam room and in the washing room. It is recommended to organize a drain through the entire floor or collect it at one point where a drain grate is installed.

But the first option will be more environmentally friendly. Important! Under no circumstances should a bathhouse drain be connected to a common septic tank; it will simply choke due to volley discharges. You need to dig a separate one.

drain hole The subfloor is first insulated with expanded clay, then concrete screed downhill This work can only be done in summer, as the concrete will not be strong if it is poured in the cold. The cement is mixed with the addition of a water-polymer emulsion (at the rate of 200 ml per 10 liters of concrete). The dried and already hardened foundation is coated with bitumen mastic, then left for a week. It is advisable to build a primitive water seal that can eliminate.

It cannot be strictly connected to the log house. The ends of the logs, on which the floor with slots are laid, are inserted into the slots of the lower crown. It is advisable to make the logs from “tar”. The floor may have slots or a ladder. In the vestibule it is always solid. It is recommended to use a tongue and groove board for the floor.

It is placed sequentially, each crown is fixed with dowels - round dowels (it is advisable to take oak ones). A hole for fastening half the thickness of the previous one is drilled through the log, all the way down. They take it off. They put caulking. Insert the dowel by piercing the caulk with it. Thread the top log onto the dowel. Repeat in a checkerboard pattern.

Do not forget to remove a piece of log in those places where there should be openings for windows and doors on their upper side.

Caulk is laid between the logs in a stretch, and then the finished log house is caulked with a cord.

Residential buildings are insulated with synthetic waterproofing agents, but this is not suitable for a bathhouse. Jute will replace traditional moss and hemp. It literally fuses with the wood and seals the room perfectly. This type of caulking is sold in sets (tape and cord).

Don't forget about the so-called technological break. The finished log house is sewn up on top with any auxiliary material, including cardboard, and covered with film for drying and shrinking. The process can take from six months to one and a half years. Only after this period has expired can construction continue.

Openings are cut down from the marks left with mandatory control by a hydraulic level. The trimmings will go to the ceiling and furniture. You can immediately make a frame for the doorway. Since the log house “walks” constantly, the usual door frame will not withstand changing load. Eat special technology, according to which only vertical parts are fixed, which eliminates its deformation. To do this, mark a hole for the door along a hydraulic level or plumb line, and remove the wood according to the intended profile. The height of the opening should be 5–7 cm greater than the door so that there is freedom for deformation. It is then recommended to fill this gap with tow and then cover it with platband. The edges of the logs are trimmed so that the platbands can be secured.

It is recommended to choose a suspended ceiling due to its durability and cost-effectiveness. This design consists of beams connected to a log house, which also serve as rafters. After constructing the ceiling, it is caulked with jute, covered with roofing felt and insulated with mineral wool.

The roof is suitable gable. The rafters are mounted from timber.

All work takes place in several steps:

If the frame was raised correctly and given enough time to shrink, then no interior decoration of the walls will be needed.

These parts can be bought or made yourself (from tongue-and-groove boards with dowels).

Installation should be carried out according to the following plan:

Bathroom furniture can be used for a steam room (shelves) and a washing room with a dressing room (benches, table).

Shelves come in different widths. This depends on personal preference, although there are some design traditions that allow you to calculate the minimum size suitable for a person of average height and build. It is customary to increase the average sizes to comfortable ones.

The minimum distance from the shelves to the ceiling should be at least 110 cm. In such a bathhouse you will not overheat on the upper tier, and there will be enough space to sit or lie with your legs raised. There are people who like to wave a broom very actively. Then it makes sense to leave it at the top more space(up to 1.5 m). The lower tier is traditionally located no lower than 30 cm from the floor of the steam room.

It would be advisable to make the shelves not from pine, but from linden, since it has lower thermal conductivity and does not emit resin. The frame can be made from timber, then sheathed with prepared boards.

Even at the construction stage, it is necessary to use modern impregnating compounds that can withstand high temperatures and humidity without harming human health. This way you can protect the building from fungus and rot. Those that are suitable for the ceiling cannot always be used to cover furniture.

Manufacturers of varnishes and paints (Senezh, Empils, Rogneda, Dulux, Tikkurila, Nobel, Belinka, Teknos) produce many such products with water-repellent natural substances such as paraffin, wax, oil. They are divided into those suitable for external walls, internal surfaces, which a person does not touch with his body (ceiling) and furniture.

Pyroprotective and antiseptic impregnation of logs is usually done at the timber mill, but it must be done again after construction.

The first application of the compositions to furniture is carried out immediately after its manufacture on a dry and clean surface, or even before manufacture (on wooden blanks). The product should be evenly distributed with a sponge, soft cloth or brush. Due to the thick consistency, a spray gun will not work.

For all sauna stoves there is a single condition, the fulfillment of which is mandatory - lengthening the combustion channel so that the door is located in the dressing room (firewood is placed in it in that room).

You can install a metal stove by purchasing it ready-made, or build a brick one yourself (it is much better due to its slower heating and long-term heat transfer). The most difficult thing in this case will be to correctly remove the chimney through wooden roof, insulating it with special metal sheets and vermiculite.

Stones must be selected as carefully as possible. They must have the following qualities:

The stones should be:

If the heater is made correctly, then unforgettable moments of steam await you.

Only a steam room provides the healthiest and only correct ratio of humidity and heat. But even there there are extreme values. This is also confirmed scientifically. The best state of health at a certain combination of humidity and temperature is graphically expressed by a homeothermal curve. Below the first curve is the optimal combination of temperature up to 90° and humidity up to 80%, which is what the Russian steam bath provides.

While in the steam room, the body is washed with hot, humid air, especially when exposed to it with a broom, due to which everything warms up. In this case, there is a constant flow of oxygen to the tissues.

After being in the steam room, you need to plunge into the ice plunge pool.

Steam in a Russian bath trains blood vessels, improves immunity, reduces weight and pleases the soul. And if it is also built with your own hands, then the pleasure increases many times over.

A bathhouse built in Russian traditions is considered ideal place to cleanse the soul and body. By visiting it regularly, you can maintain your health, stay youthful and get real pleasure. It is not surprising that many people decide to build a Russian-style bathhouse with their own hands.

The Russian bathhouse, which our ancestors built, includes two sections: a dressing room and a steam room. Most big size this room is 2.3x4 m, the smallest is 5x6 m. Baths with such dimensions are again popular.

1 - dressing room; 2 - steam room and washing room; 3 - shelves; 4 - oven

The construction of a traditional Russian bathhouse implies:

When drawing up a bathhouse design, you should not forget that the steam room and washing room will be used by several people at once. Therefore, the area and dimensions of the bath should be determined without making serious mistakes.

The second version of the bath differs in the arrangement of the shower

In order for each user to be comfortable in the bathhouse, he needs to allocate at least 1.8 m² in the dressing room and 1.5 m² in the steam room.

The average total usable area of a bathhouse for a family is 10 m². In this case, the most space should be in the dressing room, and less in the steam room and washing department.

So that people of any height can wash in Russian, the ceiling should be built at a height of 2.4 meters.

At the construction planning stage, it is necessary to reflect in the drawing the area for arranging the vestibule. This room may be needed as a place to block the path of cold air from the street.

For a vestibule, 2.32 square meters is enough. m

Followers of traditions are recommended to build a bathhouse from high-quality coniferous wood. This material is not fragile, and most importantly, it lasts a long time. The needles are also distinguished by their environmental cleanliness and low thermal conductivity, that is, they do not release heat and at the same time interfere with air exchange. A unique property of this tree is its resistance to various climate conditions.

Such a wooden building must stand on a reliable foundation

For construction, you can take one of two types of coniferous wood:

Experienced builders advise building a bathhouse from beams, since this material is cheaper and it is much easier to build walls from it. In addition, timber construction works well without a bulky foundation.

The timber structure looks simple, but is easy to assemble

If you opt for rounded logs, you may be severely disappointed: a log structure takes a long time to settle, which is why it will not be possible to put it into operation earlier than a year and a half after construction. Unlike a log bathhouse, a timber structure can be safely used six months after the completion of construction work.

When purchasing beams, you should use a tape measure to check the material for compliance with the specified dimensions, and then make sure good quality construction raw materials.

List of materials and tools

To build a Russian bathhouse, you need to stock up not only on beams and bricks, but also:

Step-by-step construction of an object with your own hands

, the layer of which is smoothed with cement mortar;

The corners are connected in 4 steps, and the ends - in 3 steps

Wooden sheathing on the floor prevents your feet from touching the cold floor

Finishing work begins after the structure has settled. First of all, all surfaces inside the bathhouse are coated with an antiseptic composition.

Interior finishing involves performing tasks such as:

Lining is laid on the ceiling and wall

If the most popular construction raw material for the interior decoration of a bathhouse has become only lining, then many materials are in demand for cladding the external walls of a building:

The material extends the service life of the structure

In the steam room it is customary to use magmatic rocks. Formed during a volcanic eruption, they are resistant to extreme heat. Igneous rocks that have a positive effect on human energy include:

In addition to benefits, this stone gives aesthetic pleasure

Metamorphic rocks can be placed on the stove, which tend to normalize blood composition and improve well-being. We are talking about stones such as:

This stone goes perfectly with brickwork

To create steam in a bathhouse, you can use fully crystalline rocks, for example:

These stones are able to regenerate cells of the nervous system, increase immune strength and have a beneficial effect on the functioning of the thyroid gland.

The length of such a stone is about 20 cm

If you want to break away from tradition, then it is better to use cast iron stones - balls produced by industry - as steam generators in the bathhouse. They instantly heat the room and retain heat for many hours. True, cast iron stones are subject to rust after a short service life and carry no useful properties for humans.

You definitely cannot place sedimentary and siliceous rocks on the stove. Their structure is porous, which means that when they cool sharply, they become covered with cracks and small particles scatter within a one meter area.

The main requirement for using a bath concerns the creation desired temperature. This one is in the steam room physical quantity should be between 55–77 degrees. The temperature indicator is selected individually, that is, it depends on the preferences of the bathhouse owner. It is customary to heat the washing room to 40°, and the rest room to 20°.

In order for the bathhouse to serve for a long time and properly, you need to use it according to the rules:

The owner of the bathhouse will have to carefully care for wooden surfaces. Elements inside the bathhouse made of wood should be coated twice a year. special means to protect against fungi and rot. External treatment It is recommended to repair the wooden walls of a building after two years of operation. To do this, it is better to use antiseptics that contain wax.

Wood deteriorates over time and therefore needs careful care

So that the stove of the Russian bathhouse gives required quantity heat, you need to be able to regulate the traction force. To do this, open the chamber door more or less to accumulate ash. Excessive draft will cause the furnace to heat up too much, and this will speed up the time of equipment failure. If the force forcing air into the firebox is normalized, then the stones in the bathhouse warm up to a standard temperature.

When firing the stove, you should monitor the operation of the chimney. The consumption of firewood can be minimized, and the efficiency of heat supply can be increased, just by not completely covering the chimney damper.

Video: building a bathhouse from scratch

You can get true joy from building a Russian bathhouse. It is clear that this work is impossible without skills and labor, but the result evokes pride. This feeling is even stronger if the object was built on its own.

Building a bathhouse from a log frame is not an easy task, but the construction technology, choice of materials and even the exact sequence of actions have long been known and worked out by many craftsmen. This material explains all the key points that will help in building a log bathhouse: from laying the foundation to interior decoration.

The steam bath has been known since the time of the Scythians, who carried with them special bath tents and camp heaters. And in the 21st century, the Russian bathhouse has not become some kind of archaism, having successfully withstood centuries-old competition with bathtubs and showers. Getting rid of many ailments, removing harmful substances from the body accumulated in everyday life in the city, giving the body complete rest - all this has been achieved by visiting the bathhouse for more than one and a half thousand years.

One of the important additions to the bathhouse itself at all times was a reservoir of fresh water located nearby - in the absence of another source of water supply, water was taken from it. The special charm of the proximity of such a reservoir lies in the possibility of a contrasting ablution - after steaming in a Russian bathhouse, running out of it and plunging into the cool water of the reservoir. In addition, the natural reservoir made it possible to quickly cope with a fire in the bathhouse, which occurred quite often due to violations in the construction of the stove.

Bound today country bathhouse there is no particular need for a natural reservoir, but it is still convenient if it is located near, say, an artificial reservoir - the final decision always remains with the owner of the dacha.

The main criteria for choosing a place for a bathhouse: distance from the road, the presence of natural or artificial fencing from outside spectators (dense bushes, tree crowns, fences, outbuildings), fire distance from the main residential building of at least 15 meters.

The main rooms of the bathhouse are the dressing room, washing room and steam room (the last two rooms can be combined into one). The size of the dressing room is determined at the rate of 1.4 m2 per bather, the size of the washing room is 1.2 m2 per person. In addition, the dressing room should have space for furniture (a locker for clothes, a bench for sitting) and for storing fuel (a box for coal or firewood). In the washing room you will need space for containers with hot and cold water, stoves and space for sunbeds.

For example, for a small family (no more than 4 people) a bathhouse of the following sizes is suitable: outer size- 4x4 m; dressing room - 1.5x2.4 m; washing room - 2x2 m; steam room - 2x1.5 m. True, in a bathhouse of this size you can’t really turn around - but it also takes up little space.

In general, the size of the bathhouse is directly related to the size of the area that can be allocated for it. If the area is significant, then the bathhouse can be expanded by adding a shower cabin, lounge areas, etc.

In temperate and cold climate zones, it would be correct if the entrance to the bathhouse is located in the south, and the window openings are on its western (southwestern) side. This location of the entrance will greatly simplify the use of the bathhouse in the winter season, since the snowdrifts on the south side melt faster, and the direction of the windows will allow the premises to be illuminated with sunlight longer.

There are several of them:

The classic and most successful construction material for a Russian bathhouse has been and will remain wood - wood easily copes with waterlogging in bathhouses, removing excess moisture outside.

What wood is suitable for building a bathhouse? As a rule, baths are built from round timber of pine or spruce with a diameter of no more than 250 mm - only wood will create an indescribable internal atmosphere in the steam room. However, in some places it is better to include wood of other species in the design of the bathhouse - oak, larch and linden. For example, lower crowns and flooring logs made of oak will allow you to get a truly durable bathhouse. A nuance - the oak must be cut down “in its sap” (that is, not dead wood) and dried under a canopy. The lower crowns (no more than 4) following the first oak crown are best made of larch. The final crowns, elements of interior decoration and cladding should be made of linden or white spruce - their wood removes moisture better than others.

When do you need to stockpile wood for building a bathhouse? Round wood, wood for interior decoration, must be cut down in winter, during the period when tree trunks contain the least amount of moisture - it is easier to dry. In addition, not the entire tree trunk is suitable for building a bathhouse - only the middle part of the trunk is suitable, i.e. the top and butt are not suitable.

An important criterion when selecting wood will be the absence of cavities and streaks of resin on the coniferous round timber, dryness, sanded surface, absence of rotten areas and places of wood-boring beetle damage.

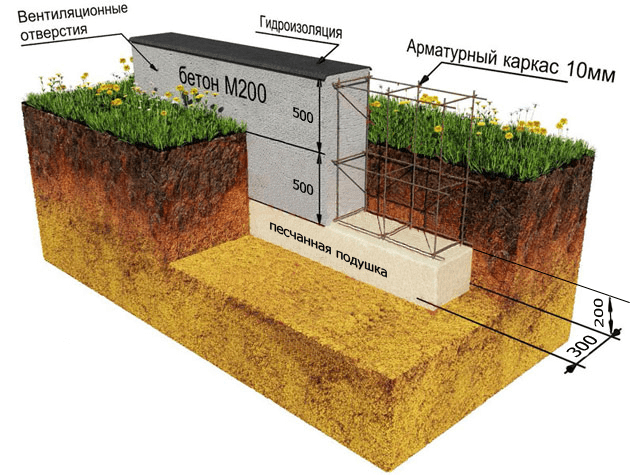

The main types of foundations for the construction of baths are strip and columnar, depending on local soils. Regardless of the type of foundation chosen, it is necessary to lay them with the utmost care - preferably to the depth of soil freezing. Preliminary work before laying a foundation of any type: clearing the site of debris, completely removing the top layer of soil to a depth of 200 mm (we remove the fertile layer).

To choose the right foundation, you need to determine the type of local soil, which can belong to one of three main groups:

Installed on slightly heaving soils: it consists of pillars laid in the corners of the bathhouse, as well as at the junction of internal and external walls. If the distance between two adjacent foundation pillars is more than 2 m, another pillar is laid between them. The depth of laying the columnar foundation is at least 1.5 m.

The pillars for such a foundation can be easily made directly at the site where the bathhouse was built; the material for them can be red brick, rubble stone, bound with concrete mortar. The main (corner) brick pillars for a columnar foundation are usually square in shape, with a side of 380 mm, auxiliary ones are rectangular, with a cross-section of 380x250 mm. If necessary, the main pillars are made of two bricks - with a section of 510x510 mm. Saving rubble stone and brick during the construction of a columnar foundation is achieved by filling the foundation pits with sand - half their depth; coarse sand is laid in layers (each layer is 100-150 mm), filled with water and compacted.

When building a bathhouse with your own hands, you can also make foundation pillars yourself. To do this, you will need a collapsible formwork made of boards, coated on the inside with a non-hardening lubricant such as Emulsol. You need to place iron reinforcement inside the assembled formwork, then pour the concrete mixture.

To cast foundation pillars inside holes dug for them, sliding formwork made of roofing iron, plastic, roofing felt or thick cardboard is used. From the material chosen for the sliding formwork, a pipe with a diameter of 200 mm is created, which is placed in a foundation pit of a larger diameter - from 300 mm. The free space around the formwork is filled with sand - it will act as a lubricant and prevent the concrete pillar from rising when the soil swells. Reinforcement tied with thick wire is inserted inside the formwork, then a concrete mixture is poured, which must be thoroughly compacted. Using wire handles pre-fixed to the sliding formwork, it is lifted by swaying by 400 mm, sand is poured on the outside and a new portion of concrete is poured.

Asbestos-cement pipes can be used as a columnar foundation; they are durable, not subject to rotting, and their outer surface quite smooth, which allows them not to change their position when the soil swells. Asbestos-cement pipes are also filled with concrete; their underground part must be coated with construction lubricant for mineral based, to reduce the risk of freezing to the ground.

In the spaces between the foundation pillars of the external walls of the bathhouse and the internal walls of the steam room, brick walls are laid out; their thickness is sufficient - brick and even half a brick. Such brick walls must be buried 250 mm into the ground.

The foundation pillars and brick walls between them are raised to a height of 300-400 mm from the ground level; they need to be leveled with cement mortar and covered with roofing felt for waterproofing. During casting, metal embedments of the required shape are installed at the ends of the pillars - they are designed to fasten the bathhouse frame to the foundation.

When building a bathhouse on heaving soils, it will be necessary to create a strip monolithic foundation.

Sequence of work:

The reinforcement laid at the bottom of the foundation trenches must have a cross-section of at least 12 mm; it is laid along each of the two sides of the trench and knitted into a frame, lifted to its middle using brick fragments.

The composition of the concrete mixture is calculated in the proportion 5:3:1 (crushed stone: sand: cement), the sand used must be dry and clean (washed). Calculating the volume of concrete required to pour a strip foundation is quite simple; you just need to measure the width, depth and total length of the foundation. For example, with a width of 0.3 m, a depth of 0.4 m and a total length of 22 m, the following volume of concrete mixture will be required:

One of the difficulties when preparing a dry concrete mixture is the lack of scales. construction sites. Therefore, this method of calculating dry components for concrete will be useful to you: one 10-liter bucket holds from 15 to 17 kg of crushed stone, sand - from 14 to 17 kg, cement - from 13 to 14 kg.

The formwork is placed in such a way that the concrete foundation cast into it protrudes 100 mm above the ground level. As the concrete mixture is poured into the prepared formwork, its mass must be pierced repeatedly with a bayonet shovel or a wire probe, and the outer side of the formwork must be tapped with a hammer (we eliminate air pockets). Then you need to wait for the foundation to completely harden, approximately 5 to 7 days. When carrying out foundation work in the cold season, after pouring the concrete, the formwork must be covered with PVC film and covered with sawdust or other insulation on top.

After the expiration of the period allocated for drying the cast foundation, we proceed to waterproofing it and lifting it in brick rows (if lifting the bathhouse is not required, then after waterproofing we proceed to the cement screed). You will need the following materials:

Roofing felt (roofing felt) is cut into strips sufficient for laying on a concrete foundation, then laid on top of the foundation with bitumen mastic (for roofing felt - tar mastic). The brick is laid using a single-row ligation method: laid on a layer of roofing felt masonry mortar, on it - the first brick row “in a poke” (across the foundation axis), then a masonry mesh is laid, a mortar is placed and the next brick row, but “in a spoon” (along the axis of the foundation). Each new row brickwork accompanied by laying a masonry mesh, laying “in a spoon” and “in a poke” alternate with each other. In the 3rd or 5th bonded rows of masonry, you need to install ventilation vents from pipe scraps - 5-7 vents are enough for the entire foundation. The number of brick rows depends on the desired foundation height.

The last row of brickwork is covered with a cement screed (mortar composition sand:cement as 1:2 or 1:3), with a 20 mm layer.

We create the foundation for the stove and assemble the sauna frame. If capital masonry of the heater is planned, it requires an independent foundation, that is, not connected to the main foundation.

The floor in the bathhouse can be clay, earthen, wood or concrete. By and large, it does not need thermal insulation, since the temperature at its level is practically no higher than 30 ° C. A wooden grate, cork mats or mats are usually laid on the surface of the bath floor - their task is to relieve bathhouse visitors from the sharp feeling of cold caused by touching the floor at the exit from the steam room. For self-drying, the flooring is raised above the level of the main floor.

The main disadvantage of a wooden bathhouse floor is its frequent waterlogging - water, penetrating through the cracks between the boards, will accumulate in them, causing rot and the appearance of an unpleasant odor. Wooden flooring wears out quickly, acquiring an unsightly appearance, and may require replacement after 6-8 years. Tile tiles would be more practical for bath flooring - they are easier to care for, they are not susceptible to moisture, which easily flows down its surface.

The floors in the bathhouse rooms must be placed at different levels: the steam room floor is 150 mm above the level of the washing room floor (we retain heat), the washing room floor is 30 mm below the floor level in the dressing room (we protect it from water).

Since installing a concrete floor covered with ceramic tiles in the washing room and steam room is more profitable than a wooden floor, we will consider this option.

There are several ways to install a concrete floor in a bathhouse. First of all, we prepare the base for the formation of a warm floor - it consists of a 100 mm layer of sand and a 100 mm layer of medium-fraction crushed stone, laid sequentially. Each layer should be well compacted and leveled. Then lay roofing felt on top, covering the walls with it to the height of the future floor.

Further actions:

If the base of the bathhouse is raised significantly above the ground level (from 300 mm), square-section wooden logs (side 150 mm) will be required for flooring. If the dimensions of the bathhouse premises do not exceed 2000x3000 mm, then the supports for the logs will be the frame logs. At large sizes Additional supports for floor joists will be required; they are pillars made of concrete or brick (250x250 mm) and are placed at a distance of 700-800 mm. Support pillars for logs it is necessary to place them on a multi-layer base of sand, crushed stone and concrete - each 100 mm thick.

Important! Before forming the base to support the logs, it is necessary to make a foundation for the stove and build a sewerage system.

The wood for the logs can be oak, larch or coniferous trees; the logs should be treated with tar or an antiseptic before installation.

Solution flooring in this case it is as follows: the concrete space between the foundation is covered with roofing felt with the walls overlapping to the height of the floor, filled with slag or expanded clay (a layer of 200 mm of foam can be laid between the layer of roofing felt and bulk insulation), a subfloor made of 29 mm edged boards is attached to the underside of the joists. Then a PVC film, foil mineral insulation, and another layer of film are laid for vapor barrier. Pour a 5 mm layer of concrete with filler on top small fraction, create a slope under the drain hole - after 3-4 days we lay ceramic tiles.

Don't forget to bring the foundation for the stove to floor level.

The floor in the dressing room is made of 19-29 mm tongue-and-groove boards made of coniferous wood.

An important point: when finishing a clean floor, and indeed the entire steam room and washing room, do not use synthetic Construction Materials— the condition is especially relevant for a steam room!

To drain wastewater from the bathhouse you will need: a pit with a water seal, a well for Wastewater and pipes that drain dirty water into a pit and then into a waste well.

The pit is torn off from the outside of the bathhouse foundation, and gravity pipes made of plastic, cast iron or ceramics are inserted into it from the steam room and washing room ( metal pipes will rust quickly).

The pit should be 500 mm from the foundation, its depth should be 700 mm, and its cross-section should be 500x500 mm. The walls of the pit are covered with a 100 mm layer of concrete, and a 110 mm drain pipe(s) from the bathhouse is inserted into it under the foundation. The main well for drainage, containing at least 2 m3, must be dug at a distance of at least 2.5 m from the pit - the further the better. A pipe is supplied to it from the pit, laid at a slope at a depth of 1.5 m (below the freezing depth), its outlet from the pit must be located 100 mm from its bottom. After entering drain pipe, the main drainage well is filled with gravel or sand 1 m from the bottom, soil is poured on top - in a layer of at least 500 mm. When laying, carefully compact each layer.

Before leading the drain pipe into the pit, a galvanized water seal is installed, located under obtuse angle to the drain pipe from the bathhouse. Its edges and upper side are hermetically attached to the walls of the pit, the distance from its lower edge to the bottom should be no more than 50 mm - thanks to this design, unpleasant odors and cold air will not penetrate into the steam room (washing room) through the drainage hole.

To prevent freezing in winter period The pit must be covered with two lids of the appropriate size (wooden or metal), felt must be laid between them, and the top lid must be covered with expanded clay, slag or sawdust.

It is better to make a log house for a bathhouse to order from professional performers; its production is quite difficult. The finished log house in disassembled form must be brought to the construction site and assembled according to the numbering of the logs. The crowns are fastened with 25 mm steel clamps. total length up to 150 mm, tooth length up to 70 mm.

The roof structure of the bathhouse includes rafters, sheathing is attached to them, then roofing material. Choice final design roof depends on the roof covering with which it will be covered. The rafters are attached to the last crown of the frame (preferably the penultimate one) using tenon brackets. As a rule, the construction of baths involves the arrangement of one or gable roof, the slope angle (from 10° to 60°) which depends on the abundance and amount of precipitation in the area. Please note - the steeper the roof, the more material is required to create it.

Single-pitch rafters located at an angle are secured with two external or internal and external supports. If the span of the rafters exceeds 5 m, they are supported with additional struts. The rafters of a gable roof rest with their lower ends on the walls, the upper ends are connected to each other, forming a ridge.

The roof of the bathhouse can be covered with any material (slate, tiles, roofing felt, galvanized, etc.), with an overlap of at least 500 mm on the walls.

The attic space must be made ventilated, that is, equipped with two doors at opposite ends of the roof.

We make a blind area along the perimeter of the foundation: completely remove upper layer soil, we go 200 mm deep at a distance of 600-800 mm from the base of the bathhouse, lay a 100 mm layer of gravel (crushed stone, expanded clay) and then level it. We lay expansion joints (19 mm board covered with resin or bitumen, in increments of 2-2.5 m perpendicular to the foundation), fill with a 100 mm layer of concrete. Before the concrete sets, its surface must be ironed - cover with a layer of dry cement of 3-5 mm. After 3 days, the line of contact between the blind area and the foundation of the bathhouse must be covered with bitumen to waterproof it.

Performed to insulate a log house - sealing the cracks between its logs, the material for caulking is traditionally flax tow, red moss, hemp hemp, wool felt. Natural materials for caulking can be replaced with factory-made ones made from jute and flax fibers: flax batting and felts - jute and flax-jute. The advantage of factory-made caulking materials over natural ones is their resistance to moths and fungi, and it is easier to work with factory-made material, since it is produced in the form of a continuous strip of a given thickness and width.

The caulking of a log house is carried out during its assembly - the caulking material is laid between the logs during their laying. After the roof is built, full caulking is carried out - from the outside and inside log house, after a year - re-caulking (the log house settles - the logs dry).

The main tools for caulking are a spatula and a mallet; you can make them yourself or purchase ready-made ones. Both of these instruments are made of wood (ash, oak or beech). The caulking shovel looks like a wedge with a handle 200 mm long and a pointed blade 100 mm, the thickness of the handle is 30 mm, the width of the blade at the base is 65 mm, at the end - 30 mm. The wooden mallet has a round shape: the diameter of the handle is 40 mm, its length is 250 mm, the diameter of the striking part is 70 mm, its length is 100 mm.

Caulking is done in two ways - “set” or “stretched”. The second way to caulk is as follows: we collect the caulking material into a strand, lay it in the gap between the logs and push it there with the help of a spatula, filling the gap completely, without gaps. Then we collect the tow with a roller, apply it to the caulked groove, take out small strands of material from it, wrap them around the roller and drive it into the groove using a spatula and a roller - with force, until you are completely sure that the groove (slot) is filled.

The first method of caulking log houses is designed to cover large grooves (slots). We twist the material for caulking into 2 mm strands, form several loops from them and drive them into the gap. Loops are collected in a quantity sufficient to completely fill the gap.

Rules for caulking:

Under no circumstances should you caulk only one wall - it will rise and cause the frame to warp and you will have to disassemble/assemble it again. Let us remind you once again: caulking is done in a “bottom-up” direction along the perimeter of the log house.

There are many design options for bathhouse stoves; they can be heated with wood, gas, liquid fuel, or use built-in heating elements and heated by electricity; they can be brick, cast iron or metal. Brick kilns in bathhouses they are made with a wall thickness of “half a brick” or “a whole brick”, masonry seams must be bandaged especially carefully, striving for their smallest thickness to achieve the greatest efficiency of the stove. Only red brick is used for laying the stoves. The furnace of the stove is led into the dressing room, its remaining three walls are located in the washing room (steam room), and the distance from them to the walls of the washing room must be at least 250 mm - in this case, the heat will not go “into the walls”.

For a cast iron or metal stove, the formation of an independent foundation is not required - only for a brick one.

Heaters installed for those who like to steam are equipped with a chamber containing stones of various weights (from 1 to 5 kg). Rubble, pebbles, boulders and granite are suitable for filling the heater chamber. The design of these stoves is extremely simple - similar to kitchen stoves, heaters differ from them by having a larger pipe or the presence of a chamber with stones.

To obtain the highest temperature in the steam room, you need to add cast iron pigs to the stones in a percentage ratio of 80:20 (stones: pigs). For every 1 m 3 of steam room you will need at least 6 kg of stones and cast iron pigs.

By maintaining a distance of 40-50 mm in the furnace between its walls and the water heating boiler, the effect of all-round blowing of the boiler with hot gases and rapid heating of water is achieved.

For better traction you need to remove chimney as close to the roof ridge as possible. When laying a chimney through the attic, be sure to fluff the pipe 380 mm. Remember that the pipe should not pass closer than 150 mm near the roof sheathing and rafters (fire safety standards).

To wash one bathhouse user, at least 8 liters of hot water are required. This amount can be provided in several ways: heat a container of water on a heater, use geyser, install electric heater- boiler. If available central water supply, the pipeline to the bathhouse leads from the main house - the water from such a pipeline system must be drained in winter, otherwise it will freeze and burst the pipes.

Water can be taken from a well or well by installing submersible pump for its injection and equipping such a water supply system with purification filters. And in this case, in winter, the water must either be drained after each use of the bathhouse, or the supply pipes must be insulated.

You need to extend an independent line to the bathhouse to supply electricity, and the easiest way is to do it by air (air). For the air supply you will need a special cable - we sweep away the “bare” aluminum cable right away, settling on two options: SIP (self-supporting insulated wire) and VVGng. The first type of cable is very good, it has a long service life (more than 30 years), it is durable and does not need to be supported by a supporting cable. But it is extremely difficult to carry out installation work with it, because it is too thick (minimum cross-section - 16 mm2). Aluminum SIP cannot be pulled through the attic of a bathhouse according to fire safety standards; it is required to be attached to special anchor clamps - considering the amount of costs and hassle with its installation, its cost will be expensive.

A simpler solution is air copper cable VVGng, fixed to the carrier steel cable. The cable is suspended from the cable on a plastic-insulated wire; its service life is up to 10 years, after which it must be replaced (!). For a single-core VVGng cable (of course, there must be two cores - each of them must be in an independent double braid), stretched over the air to the bathhouse, the optimal cross-section will be 2.5 mm 2 - it is not known exactly what electrical equipment the owner of the dacha will want to power from it in future.

All junction boxes, sockets and switches, electrical panel should only be outdoor installation. According to the rules against fire safety It is prohibited to install junction boxes, switches and sockets in the washing/steam room - only in the dressing room. Don't joke about the possibility of a short circuit in wooden building— all internal wiring of the bathhouse must be done only in non-flammable corrugated hose, secured with special clips, cable passage through the partitions must only be through a steel pipe.

Try to arrange the cables in the junction box, socket or lamp so that they enter there from the bottom or side, but not from the top - a drop of condensate sliding along the braid can cause a short circuit.

All electrical appliances must have a moisture protection class of at least IP44 (preferably the maximum - IP54). Install simple lamps - a metal body, only a glass shade. All connections of the internal cable routing are made only on the terminal block, no twists. And install an RCD in the shield, setting it to 30 mA.

To work in the electrical panel and install an RCD, be sure to invite a qualified electrician if you are not one yourself!

Internal partitions in the bathhouse can be brick or wood, followed by heat and moisture insulation in both cases. The partition between the washing room and the dressing room in which the stove is installed must be made of brick, or there are brick inserts in it with single brick masonry - on the sides in contact with the stove body.

Interior finishing is usually carried out in cases where the bathhouse itself is built of brick, stone or timber - here the finishing scheme is classic: insulation, vapor barrier film and lining. In addition, when performing external and internal finishing, you will have to rebuild the ventilation system of the bathhouse, because log logs will be covered with casing and will not be able to provide adequate ventilation.

The ceiling is formed in two layers - rough and finishing. The rough ceiling is attached to the horizontal roof joists, if necessary reinforced with intermediate beams. Its area is covered with insulation - expanded clay or slag. From inside the washing/steam room rough ceiling insulation and a vapor barrier film are attached, after which the ceiling is covered with a finishing finish - linden, pine tongue and groove board (20 mm thick - the thicker the board, the longer it will retain the woody smell).

In the bathhouse you need to install small windows (on average 500x700 mm) and cut them low - enough so that someone sitting on a bench can look out through them. The windows in the bathhouse are always double glazed, depending on the size - with a window or completely hinged - for quick ventilation.

Doors in bathhouses must be installed so that they open outward for fire safety reasons. The material for the door leaves is a tongue-and-groove board (40-50 mm) or a board with a selected quarter; the boards are fastened with dowels. The size of the sashes must be deliberately reduced by 5 mm - more than needed for the actual distance between the quarters of the jambs - otherwise, when the humidity increases, the sashes will swell and it will be difficult to open (close) it. The optimal door size in the washing compartment of a bathhouse is 600x1600 mm, in the steam room - 800x1500 mm, with a threshold height of about 300 mm above the floor (it’s uncomfortable to walk, but it will keep you warm). The hinges for hanging the door leaves are brass, opening into the dressing room (washing room) and into the washing room (steam room). Door handles are wooden (especially in the steam room).

The material for the shelves is linden, pine, poplar or aspen. The minimum length of the shelves is 1800 mm, width is 500-800 mm. The distance between the “floors” of two-row shelves should be at least 350 mm, the minimum distance from the second row to the ceiling covering is 1100 mm.

The lying surface is formed by a board with a width of 80 mm, a thickness of 40 mm, and a gap of 15 mm wide is formed between the boards. A distance of 10 mm is maintained from the wall to the shelf. Boards for sheathing shelves are attached to a frame made of timber with a cross-section of 50x70 mm in two ways: from above - using nails, the heads of which are recessed into the wood; from below - using screws. For fastening, choose nails and screws made of stainless steel or copper.

All corners in the shelf structure are rounded, the surfaces are carefully cleaned with zero-grade sandpaper.

For greater convenience, the shelves in the steam room are equipped with a headboard: the height at the beginning of the rise is 30 mm, the length of the headboard is 460 mm, the final highest height- 190 mm.

When choosing material for creating shelves, be careful - it is believed that knotty areas are more dense and can lead to skin burns. Therefore, try to choose boards and timber without any knotty areas or with a minimum number of them.

Protect the bathhouse premises from the threat of fire - lay a steel sheet in front of the furnace firebox, make sure the stove doors are securely fastened, install fire extinguishing means nearby (a container with water, sand and fire extinguishers). Make sure you can open the steam room and washing room doors freely when lighting the sauna. Do not block passages or the space in front of doors and windows.

Almost every owner of a plot of land, sooner or later, thinks about building a bathhouse. After all, a bathhouse is not just a room for washing, but also an important element of a country holiday. The construction of a turnkey bathhouse can be ordered from professionals for a tidy sum, or you can try to build a bathhouse with your own hands.

After reading this article, you will be able to select a project, find out the sequence of the construction process, get acquainted with boiler models and find best option baths for your dacha.

Before starting construction, it is necessary to develop a bathhouse design. To do this, you don’t have to contact an architect; you can develop a simple project yourself, especially since there are now many computer programs for design.

Think about what size bathhouse will be optimal for your family. What rooms will be located inside the bathhouse? What materials to make the foundation, walls and roof from, do not forget also about finishing the bathhouse. An important point in design is the placement of the boiler and the method of firing it.

Below you can see popular bathhouse projects:

Once you have decided on the size and materials for the bath, you need to create a cost estimate.

To build a bathhouse, several types of foundations are used. Depending on the weight of the walls and soil characteristics, the following types of foundations are made:

As practice has shown, the most reliable foundation for almost all types of soil is a concrete strip foundation reinforced with reinforcement.

To make a reinforced strip foundation for a bathhouse you will need:

In the place chosen for building a bathhouse, mark a trench for the future foundation. To mark, use a tourniquet stretched between the pegs. The width of the trenches is based on the weight of the wall material. For one-story bathhouse made of wood or brick, it is enough to make a trench 30-40 centimeters wide. After installing the markup, do the following:

The foundation for the bathhouse is ready!

The following materials are used for the construction of walls:

Since the construction of a bathhouse from logs or bricks is already quite widely described on the Internet, let's consider the construction option frame bath from timber 15x15 and 5x10 centimeters and boards with a section of 2x15 centimeters:

Please note that the manufacture and insulation of the ceiling can also be done after the roof has been installed.

There are three types of roof for a bathhouse:

Usually the first two options are used for a bath. Let's look at the option of a gable roof covered with metal tiles:

The manufacture of the roof begins with the installation of the Mauerlat. In the case of frame walls, the role of the Mauerlat is performed by the upper outline.

For a more visual understanding of the roof fastening, here is a drawing:

All dimensions of roof elements are given in the list:

Please note that the less you slope the roof, the more snow load it will bear in winter. Also, a small roof slope can lead to poor water drainage and leaks.

The design of the floor depends on the type of room. In the recreation room, ordinary wooden floors are made. In the washroom and steam rooms, the floors are made of two levels:

If you want to make a floor of porcelain stoneware or tiles, then they are simply laid on the first level at a slope towards the drain hole.

In order to make a concrete floor and drain in a bathhouse you need:

At the second stage, wooden floors are made:

Don't forget before you start installation wooden floors, treat all parts with wood impregnation. When making floors, keep in mind that they should be higher, or at the level of the upper edge of the foundation.

The boiler model for a sauna will largely depend on your financial capabilities and the fuel you will use for heating. If you know how to use welding, then you can make a simple boiler yourself from thick sheet iron. If you prefer more advanced colas with gas or electricity, you can purchase them from specialized companies.

The boiler in the steam room is installed in such a way that the combustion chamber is loaded with fuel either from the street or from the rest room (dressing room). The boiler itself, for fire safety purposes, is located 10-15 centimeters from the nearest walls. The walls are as high as the boiler and covered with iron sheets. A good decision, will cover the boiler with bricks, thereby reducing its cooling time and protecting the walls from fire.

When installing a chimney for a boiler, Special attention Pay attention to the place where the pipe comes into contact with the ceiling. The opening for the chimney should be insulated with refractory material. Also, pay attention to the place where the chimney pipe exits through the roof. This area is usually prone to leakage, so it should be sealed thoroughly. Below are the options for boilers for baths:

After the bathhouse is built, it is necessary to equip it:

After arrangement, you can safely invite guests to take a steam bath in your personal bathhouse!

You can also watch the instructions for assembling a mini-sauna for a summer house without a foundation in the video:

Except traditional materials and design for the bath, there are many alternative solutions. Below we present photographs of the most unusual baths:

At the end of the article, I would like to remind you that heating a bath is associated with fire and high temperatures. Therefore, when building a bathhouse from bricks, logs, cinder blocks or boards, pay great attention to fire safety. This warning also applies to electrical wiring, since the rooms inside the bathhouse have high humidity air and the risk of a short circuit due to condensation is very high.

We hope that reading our article will encourage you to build a bathhouse yourself!

It’s hard to imagine without an indispensable attribute - a hot bathhouse, which raises vitality with the aromas of birch broom and eucalyptus steam. Bath procedures They cure many diseases, relieve stress and provide an opportunity to sincerely communicate with loved ones. So, no matter how you look at it, you can’t do without her, my dear. The topic of our research is a do-it-yourself bathhouse. , photos, important nuances and invaluable experience of practitioners - all this is in this material.

Read in the article

Perhaps it will be news to some that the bathhouse cannot be placed in any place. There are many official and practical principles which should be followed. Moreover, choosing the wrong location can lead to dire consequences. Let's look at all the rules.

There are three main requirements when planning the location of a bathhouse complex on a garden plot:

| Distance from site boundary | The distance from the bath complex to is at least three meters. The building should not obscure the territory of the neighboring plot. This gap will protect the buildings from a possible fire, because the bathhouse is a fire hazard. Another important aspect is drainage. A three-meter zone, even if your bathhouse has the most primitive drainage system, will not allow dirty water penetrate into adjacent areas. For reliability, you can lay it along the fence filled with gravel. And a couple more important points: the distance to the neighbors’ residential building should be at least eight meters (six if the bathhouse is brick). When deciding where to build a facility, keep in mind that smoke from sauna stove should not reach the windows of the neighbor's house. |

| Distance to the reservoir | On the one hand, the location of the building on the banks of a river or lake is very advantageous. And it’s easier to collect water, and the pleasure of diving into the cool waves after a steam room is guaranteed. On the other hand, you should strictly follow the rules that protect the reservoir from negative influences. To do this, the structure must be located no closer than 15 meters from the shore. This distance will also protect the structures from being washed away during floods. The coastline should be strengthened with your own hands using wooden or concrete frames. |

| Gap to residential building | The Russian one is located on the leeward side of the house at a distance of at least twelve meters. This will prevent smoke from entering the rooms. It is advisable that there are no other easily flammable structures near the building. Experts recommend maintaining a four-meter distance from the barn. |

There are situations when, with the purchase of a summer cottage, a bathhouse is inherited, as they say. In this case, of course, it is not always possible to move it to a new place in accordance with the listed rules. But, with the help competent reconstruction fire safety standards can be achieved.

The size of the plot does not always allow meeting all of the above requirements. There is only one way out - to attach a bathhouse complex directly to the house. Let's consider the advantages and disadvantages of this solution:

Bathhouse project 3x4 meters

Bathhouse project 3x4 meters  Bathhouse project 3x5 meters

Bathhouse project 3x5 meters  Bathhouse project 3x6 meters

Bathhouse project 3x6 meters Advantages and disadvantages of a columnar foundation:

| pros | Minuses |

| It can be erected with your own hands, without the involvement of special workers. Foundation installation frame structure does not require special skills. | Not suitable for brick and block buildings |

| Suitable for almost any soil (including heaving) | |

| Compensates for differences in height on the site, does not require leveling | |

| Installs in one to two days | Does not provide for arrangement ground floor or basement |

| Doesn't need | |

| Has a long service life | |

| Does not require capital investments |

The installation depth of the bases differs in:

Step-by-step installation algorithm:

| It is necessary to clear the area of debris and weeds | |

| The future foundation is marked using rope and pegs | |

| At a distance of one and a half meters from each other, holes are drilled with a garden drill with a knife of a diameter corresponding to the diameter of the pillars | |

| Cuttings of concrete pipes are installed in the holes. The height above the soil level is leveled using a laser level, the excess pipe is cut off | After the concrete has hardened, a metal or wooden one is installed. |

Advice! For lightweight design you can use plastic pipes rather than concrete ones, or wooden poles, treated with resin to protect against rotting.

Detailed video material on how to build a foundation for a 4x4 sauna with your own hands

A well-thought-out drainage system is an important point in the design of a bathhouse complex. Correct drain in the bathhouse will not only protect the base of the building from mold and rot, but will also save you from problems with neighbors in the area.

Where can you drain the sewer:

It is necessary to dig a trench in advance for sewer pipes and bring them to the place of drainage from the steam room and washing room. The pipe should be laid with an inclination of five degrees. To prevent the drain from freezing, you can insulate it yourself using heat-insulating materials.

A step-by-step guide to arranging a drainage well in the following video and photographic material:

Another significant point is the installation of floors in the steam room and sink. The simplest option is leaking floors. Water simply penetrates through the cracks between the boards. Under them there is a sealed receiving plane with a hole for drainage.

Advice! In non-leaking floors, the drain must have a water seal, otherwise unpleasant odors will ruin the pleasure of the bathing procedures.

You can also make completely concrete floors and cover them with ceramic tiles.

But it should be taken into account that it is easy to slip on the tiles, and in the steam room the ceramics heat up quickly, so you cannot enter it barefoot.

It remains to resolve the issue of water supply. In separately standing building It is better to carry out the water supply underground, in a protected enclosure. If your region has severe winters, it is worth considering heating the water supply to prevent emergency situations. Photo reports that are not difficult to find on the Internet will tell you how to install such a system.

Article