The ceiling, if it is cold, can become a source of steam condensation to a greater extent than the walls. Cold drops falling from the ceiling serve both as an irritant and as a cause for the appearance of rot and pathogens on the surface.

What kind of health is there if whole colonies of microbes live and multiply above your head?

Percentage of heat loss through the ceiling is about 42-45. If the ceiling is not insulated, then no effort can be made to heat the bathhouse to the required temperature.

How can you insulate the ceiling of a bathhouse? What is the best way to insulate the outside?

There are not so many main types of ceiling insulation for a bath - only two.

And if you are satisfied with the option of insulating the bathhouse ceiling with your own hands, then, first of all, you need to decide what kind of insulation It will be more comfortable to work: natural or artificial.

However, not only the simplicity of the insulation process and not only your personal preferences become the determining factor in choosing insulation.

The technology for building and insulating a bathhouse has been developed and improved over centuries, and it is not based solely on the presence or absence of this or that material.

The first and main thing that is important to pay attention to when insulating a bathhouse ceiling is how beneficial (or at least not harmful) it will be for health, and how long it will last.

Natural materials:

Artificial materials:

Let's start, perhaps, with a detailed analysis of insulating the ceiling of a bathhouse with our own hands using the most affordable natural insulation - sawdust.

This technology will be ideal for bathhouses with an attic. It is advisable to insulate without delay, immediately after completion construction work. If the roof and the main plank floor are installed, then you can safely begin insulation.

In this video you will clearly see how you can insulate the ceiling in a bathhouse with your own hands. How to properly insulate a bathhouse ceiling with sawdust.

Read more about insulating the ceiling of a bathhouse with sawdust in this article.

Clay- material that has been respected in Rus' since ancient times. Pliable, elastic and energy-saving, it provides a complete guarantee that your bath will remain hot even in the most severe frosts.

Bathroom ceiling insulation with my own hands clay is not just a job, but a tribute to my father’s and grandfather’s traditions.

Clay is good because it can be used to insulate the ceiling in several layers, filling the gaps with expanded clay or dry sawdust.

In order to use clay as a high-quality insulation, it must be mixed with straw, as grandmothers do in villages, performing partial renovation facades of old clay houses.

Ceiling insulation using clay– one of the most ancient, proven, reliable and environmentally friendly methods.

We discussed the details and features of insulating a bathhouse ceiling with clay in a separate section.

IN frame structure, covered with a vapor barrier, simply pour regular soil from the garden bed.

The earth needs place evenly, not in a very thick layer, and compact lightly.

This method is also ancient. Perhaps it is older than the previous method of insulation with clay.

You can use a mixture of black soil and peat.

The effectiveness of ceiling insulation with earth It justifies itself, however, it is not suitable for all rooms, but only those built separately and equipped with an attic.

In order for the temperature in the bathhouse to remain “steamy” for a long time, when insulating the ceiling in the bathhouse, you should pay attention to important details:

In order for the temperature in the bathhouse to remain “steamy” for a long time, when insulating the ceiling in the bathhouse, you should pay attention to important details:

When choosing a heat insulator, function must be taken into account which he is obliged to fulfill:

Heat from the steam room can evaporate in three ways:

If the thermal insulation for the bathhouse ceiling is done correctly, then it can easily cancel all three methods of leakage.

Any bathhouse needs high-quality insulation of the ceiling - warm air, according to the laws of physics, tends to rise upward. And if there is no thermal insulation layer along its path, then significantly more fuel will be needed to heat the bathhouse and maintain a consistently high temperature in it.

But this is not the only problem - in the absence of insulation, condensation will accumulate on the ceiling of the bathhouse, and drops dripping from above onto the head and back are unlikely to bring much pleasure to anyone. And the moisture that goes up along with the heat will contribute to the destruction ceilings and supporting roof system. The only way to avoid these troubles is to do it in a bath with cold roof high-quality insulation ceiling. And our material will tell you what and how to make it from.

Before you buy materials and take up tools, you should carefully plan your actions. A clearer understanding of the matter will save you from annoying mistakes and the need to redo everything in the future.

The first question is whether it is possible to insulate the ceiling in a bathhouse yourself? Or should we entrust this matter to a team of builders? The process of insulating the ceiling itself is not something complicated, so it is not difficult to do it yourself, even without much experience in repair and construction. The main thing is to carefully follow the technology and approach the matter responsibly. In favor self-insulation the ceiling also indicates accessibility necessary materials– they can be found in any major hardware store or on the market.

The second question is what exactly needs to be done?? Insulating the ceiling in a cold bath consists of three stages:

The result should be a kind of “ layered cake", the bottom layer of which is ceiling covering, and above it, vapor barrier, thermal insulation and waterproofing are located sequentially from bottom to top. More details about why this is necessary and how to do it will be discussed below. Now it's time to think about the choice of materials.

The melted bath maintains a very high temperature and humidity. The thermal insulation material must meet these conditions and, most importantly, not emit heat when heated. harmful substances. Besides good insulation for a bath it must be fire-resistant. It is undesirable for the thermal insulation material to be too heavy or inconvenient to carry and install. Now let's look at the materials in more detail.

It is the most common insulation option for baths and private houses; This is a fibrous thermal insulation material that exists in three types:

The main advantage of mineral wool, in addition to its very low thermal conductivity, is that it is not a breeding ground for fungi, mold, insects or rodents. For a bathhouse located on a private plot, this is especially important. It is also worth noting that this material does not burn, does not change its volume and shape when heated or cooled, and is very convenient to install due to its low weight. Mineral wool is produced in the form of rectangular panels or in the form of rolls.

As for the disadvantages, there are two of them - the ability of mineral wool to absorb moisture (especially for slag wool) and the potential harm of the phenols contained in them. Both of these disadvantages can be eliminated if you approach the issue of vapor and waterproofing wisely and prevent mineral wool from coming into contact with the air flow, especially inside the bathhouse.

Important! Small particles of mineral wool can have a damaging effect on a person’s eyes, skin or lungs, so when working with it, be sure to wear thick clothing and use gloves, safety glasses and a respirator.

Table. comparative characteristics various types mineral wool.

They are small pebbles made of clay with a porous structure. Based on the totality of its advantages, expanded clay is the most suitable material for insulating the ceiling in a bathhouse.

Expanded clay also absorbs significantly less moisture than mineral wool, but at the same time there is a need for vapor barrier and waterproofing layers still remains.

Expanded clay

At one time it was one of the leaders among thermal insulation materials. But even taking into account all its advantages, you should not choose polystyrene foam as ceiling insulation in a bathhouse - in the event of a fire, the material burns well, and its smoke is very dangerous to human life and health. It is also capable of decomposing simply under the influence of high temperatures (and they are inevitable in a bathhouse), so polystyrene foam can hardly be called a reasonable choice in this case.

Styrofoam

A natural fibrous material made from cellulose with additives that provide flame resistance and protection against rodents, insects and microorganisms. Ecowool is lightweight and has the ability to fill all cracks and gaps. Like expanded clay, it is environmentally friendly and does not emit any substances harmful to humans into the air.

However, ecowool can absorb a lot of moisture, which impairs its thermal insulation properties. Therefore, when using it, it is advisable good ventilation under the roof and high-quality waterproofing. Another disadvantage of its use is the complexity of installation - the “wet” method of application requires special equipment.

“Wet” method of applying ecowool

It is a “classic” material for insulation, which was used even before mineral wool or polystyrene foam appeared on the market. In some cases, clay can be used instead of cement, and straw instead of sawdust.

First, a dry mixture is prepared in the following proportion: for 10 parts of sawdust, take one part of cement and one of lime. The resulting dry mass should be filled with one and a half parts of water to obtain a fairly thick and homogeneous solution. The mixture is laid out on the surface and distributed in a fairly even layer.

Important! It is advisable to use sawdust that has been dried for several months or better than a year.

This material is very cheap and environmentally friendly, but it does not have such high thermal insulation as expanded clay or mineral wool. In addition, the process of its manufacture is labor-intensive, and after installation it is necessary to repair the resulting cracks (and they are inevitable).

For a bathhouse, vapor barrier of the ceiling is vital, otherwise rising moisture will not only worsen the thermal insulation properties of the insulation, but will also contribute to the development of fungi and mold on the ceiling itself and on the roof rafters. Specialized films and coatings are used as vapor barrier materials. Particular attention should be paid to anti-condensation membranes. When purchasing vapor barrier films, it is advisable to choose those with a foil layer.

Important! When working with such films, be careful and do not allow any rupture of the vapor barrier material or foil layer, otherwise its protective properties will significantly deteriorate.

As for waterproofing, it can be used as special films, which can be found in any hardware store, as well as cheaper roofing felt or dense polyethylene.

Common vapor barrier materials: 1. Geosynthetics. 2. PVC membrane. 3. Glassine. 4. Tol. 5. Aluminum foil. 6. Thermofol.

There are three main types of ceilings in the bathhouse:

Now we will look at the last type and find out how to insulate it and what nuances should be taken into account.

Floor ceilings are usually used for small-sized baths, which are heated quite rarely and seasonally. On top part walls are laid with sheet piling or simple edged boards, adjusted to each other and secured, without the use of support beams. The resulting design is very simple, but at the same time it is unable to withstand a large load, therefore it is impossible to use a thick layer of thermal insulation here.

Important! It is advisable to lay the floor ceiling slightly lower than the height of the walls in order to leave space for filling expanded clay or laying mineral wool. If this is not possible, then sides should be nailed along the perimeter of the ceiling under the roof.

The step-by-step insulation of a bathhouse floor ceiling is as follows.

It makes sense to use a flat ceiling in small-sized baths and in cases where the simplicity and speed of its installation and installation of insulation is important to you. If you are planning to make a fairly large steam room or arrange an attic under the roof to store bath accessories, then you should opt for a false ceiling.

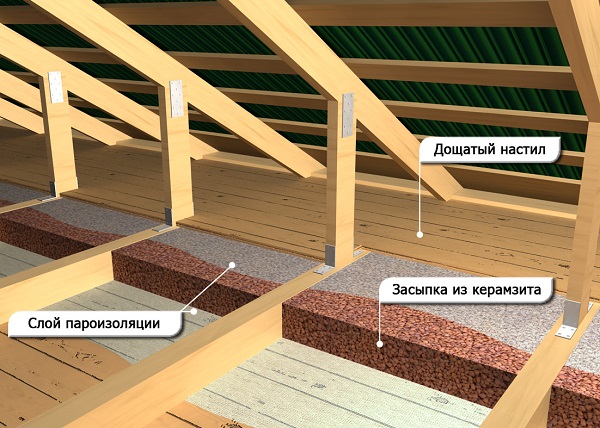

Here, it is not the flooring itself that is laid on the upper part of the wall, but support beams made of wooden beam or boards joined together. And the ceiling and floor of the attic are laid on the beams below and above. At the same time, layers of steam, hydro and thermal insulation are laid in the space between them.

The process of insulating a ceiling with a similar design depends on what material you use. For mineral wool this happens as follows.

The process of insulating the shed ceiling of a bathhouse with a cold roof looks a little different when expanded clay or a cement-sawdust mixture is used. Let's present this in the form of step-by-step instructions.

If you use a mixture of clay and sawdust to insulate the ceiling, then it is advisable to put a layer of mineral wool on top of the frozen mixture or fill it with expanded clay - this will improve the thermal insulation performance.

Important! Optimal thickness layer of a mixture of clay and sawdust for using a bath in warm time year is 50 mm. If you plan to steam in it in winter, then you will need to make a layer of insulation of at least 150 mm.

This type of ceiling design is the most difficult for self-made– first you need to make the panels themselves, and then lift them up and fix them either to the cross beams or directly to the top of the walls.

Each of the panels is manufactured as follows.

The resulting panels should be lifted and mounted, and it would not be amiss to lay solid boards on top and bottom of them, connecting all the panels to each other. The joints between them also need to be insulated with strips of mineral wool scraps. As an alternative, you can take the same mixture of cement and sawdust.

Advice! The assembly of the ceiling panels, their lifting and installation is very labor-intensive. Therefore, it is advisable to use some lifting device and work not alone or in pairs, but as a whole team.

The type of ceiling and insulation material used should be selected based on your budget. own experience construction work, the size of the bathhouse and how often it will be used.

Own bathhouse – perfect place, where it’s so nice to take a steam bath in the cold. In order to quickly heat and retain heated air in the bathhouse, you need to properly insulate all its surfaces. Particular attention should be paid to the ceiling, since according to the laws of physics, warm air masses rise upward.

Conditions high temperatures and humidity impose special requirements on the choice of insulation. When carrying out thermal insulation with your own hands, you also need to take into account what kind of design the ceiling has. Depending on this, it can be insulated from the inside or outside.

In saunas built with your own hands, there is usually an attic or attic space on top. This provides additional air gap and makes the room warmer. However, this will not be enough to keep the heat in the steam room. The ceiling of the bathhouse should be additionally insulated.

This is most conveniently done from inside the attic or attic. Insulation material is placed taking into account the requirements fire safety. It is especially important to properly close the junction with the chimney.

The distance between the pipe and the insulation must be at least 20 cm. To do this, a box of boards is built around it, and the inside is filled with fire-resistant material, such as expanded clay or mineral wool.

Access to the ceiling of the bathhouse from above through the attic provides the opportunity to insulate it different ways using traditional natural materials or modern insulation. If there is no attic, thermal insulation is laid from the inside of the bathhouse.

If there is no above the bathhouse attic space, you can carry out insulation with your own hands from the inside. For this they use basalt wool. It is important to ensure that the insulation is protected from moisture penetration.

Advice! For internal lining steam rooms choose low-density wood. Boards made of alder, linden, cedar or aspen not only create a pleasant aroma, but also provide good thermal insulation. Pine also smells nice, but tends to stick.

Properly carried out insulation of a bathhouse will ensure faster warming up and will allow you to more economically use firewood or electricity for heating. Thermal insulation can be placed from the inside or from the attic side. When building a bathhouse with your own hands, it is better to take care of high-quality insulation in advance.

If you decide to build a bathhouse on your own site, you will have to work hard to ensure that this structure performs its functions properly. The bathhouse will need a lot of things that are not needed residential building. Today we will talk about how to properly insulate the ceiling of a bathhouse outside and inside so that you truly enjoy the result of the work.

In a classic Russian bathhouse, all surfaces must be properly insulated, otherwise the structure will be unsuitable. IN equally this also applies to the ceiling. If you do not provide high-quality thermal insulation, according to the laws of physics, hot steam will be directed upward, cool there and settle on the surface in the form of condensation. During bath procedures this cold water it will drip on top of you, and this is not the most pleasant feeling.

Properly carried out thermal insulation of the ceiling will provide your bathhouse with an excellent climate

In addition, the dressing room will always be cold and damp. The result of this is the appearance of fungus and mold on surfaces.

If the ceiling insulation is carried out efficiently, then:

You need to properly plan and carry out all insulation work to ensure a stable internal microclimate, as well as improve the aesthetic and operational qualities of the room.

The following types of materials are used to insulate the ceiling:

When choosing a material, pay attention to what the ceiling structure is made of and the degree of its wear. This data is the basis for what the composition of the thermal insulation “ceiling” should be, and what installation technology should be chosen.

Let's look at the options for thermal insulation materials used for thermal insulation.

Insulation with penotherm

Insulation with expanded clay

Dried leaves are often used for thermal insulation

Such insulation can be called external only conditionally, since the insulation is located inside the attic. This option optimally solves the problem of heat loss. In this case, the materials that make up the insulation system are not subject to aggressive influence steam and hot air, eliminating the risk of condensation both on the surface of the ceiling and between the layers of the thermal insulation system.

External insulation of the bathhouse ceiling is carried out from the attic side

Before you begin insulating the ceiling from the outside, thoroughly clean the attic floor of debris and dirt. Inspect the ceiling structure for damage and, if necessary, carry out renovation work and replace damaged elements.

Be sure to treat the base surfaces with a primer and antiseptic (if necessary, mastic) to protect them from the effects of fungus, mold and harmful insects.

There are several ways to insulate a bath ceiling.

The floor of the attic, which is outer side ceiling, pre-prepare and fill with the so-called warm mixture. You can purchase it ready-made in specialized stores or prepare it yourself. The components included in this mixture provide high thermal insulation properties:

Begin installing the insulation by treating the junction areas. These are the gables rafter system, chimney. After the mixture has hardened, cover it with a moisture-proof material - mastic, special liquid, film coating.

If you use membrane sheets, take care to protect them from mechanical damage.

This kind of work is very easy to do yourself, this is its advantage. The disadvantages include the fact that if it is necessary to repair the floors, it is very difficult to carry out dismantling work.

This option is considered the simplest. You just need to cover the surface of the attic with any bulk materials: slag, vermiculite, expanded clay, woodworking waste. Usage wood waste suggests that you need to carefully treat the chimney junction areas with materials that are resistant to moisture.

Sawdust and expanded clay can be poured directly onto the base of the floor or between joists previously laid on the surface. The joists are needed to make it easier to plan the flooring later sheet material on top if you plan to lay it.

Using this method, you can also insulate the bathhouse ceiling with mineral wool in slabs or rolls. If you use glass wool for insulation, then keep in mind that you need to provide yourself with personal protective equipment: gloves, overalls, goggles and a respirator or mask. In addition, mineral wool can be left in open form, and the glass wool must be closed.

Combining dry and wet technology By installing thermal insulation, you will significantly expand the possibilities of using building materials.

Pre-level the surface, cover it with mineral wool or fill it with expanded clay. Make a moisture-proof screed on top. It can also be mounted on soft or loose insulating material.

When using this material, do not skimp on reinforcement, even if you do not plan to use the attic later.

In modern construction technologies Fundamentally new materials are used for work:

Experts consider the last two materials to be insufficiently effective.

Insulation materials in liquid form can be very demanding in terms of storage conditions. If they, for example, freeze, their thermal insulation properties will be lost.

To insulate the ceiling of a bathhouse using polyurethane foam spraying, you will need special equipment, so it is quite difficult to cope with such work on your own. Moreover, the received monolithic design will be inconvenient if repair work and dismantling are required.

Before you begin insulating the bath ceiling from the inside, carefully prepare the base. Clean it of debris and dirt, level it, repair it if necessary, and be sure to treat it with protective equipment: primer and antiseptics.

U internal thermal insulation There is a disadvantage: there is a risk that moisture will accumulate inside the insulation system. Please pay attention Special attention selection of material for finishing. It is best to choose wood for this: it is environmentally friendly, easy to process, and cheap.

Wood not only absorbs, but also easily releases moisture. Try to fit the lining or boards as tightly as possible, this will prevent water from getting onto the insulation.

Due to the fact that wood has high thermal insulation characteristics, the possibility of overheating of the materials that make up the insulation is eliminated.

As you know, we build a bathhouse in accordance with our desires and capabilities. This means that the building can have an attic or without it. And the process of installing ceiling insulation is significantly different in the first and second cases.

Standard thermal insulation scheme for a bathhouse ceiling

Such a bathhouse also needs insulation. It's not difficult to make. You just have to sacrifice a few centimeters of room height.

There is another way to insulate a bath ceiling from below. Nail 50 mm thick bars to the ceiling surface, lay a vapor barrier on them, then insulation of the appropriate thickness, and again a layer of vapor barrier.

Add more 50 mm thick bars to the resulting “pie” perpendicular to the first layer, again insulation, a layer of foil vapor barrier. This option is more labor-intensive, but effective.

In this case, the task of insulation is simplified. It is much easier to install insulation when there is additional space above the ceiling.

Construction and finishing of a bathhouse, including its insulation, is not an easy job, but it is worth it. After all, you will now have an excellent opportunity to spend your free time with pleasure and benefit for the body. The main thing is to do everything right and avoid mistakes. We hope that our tips will help you with this. Share with us your experiences or questions on this topic in the comments. Good luck to you!

The bathhouse is one of the structures that require special conditions during operation. The internal microclimate, room heating time and fuel consumption depend on the correct device. Under the term " correct device“They understand, among other things, the insulation of the bathhouse ceiling.

Based on the roof structure, there are two types of baths: attic and non-attic. A leak warm air in or attics is much less, since not only the ceiling, but also the roofing and heat-insulating materials used during the construction process become obstacles in its path.

The air in the under-roof space itself will also stop heat leakage, but this does not mean that in bathhouses with an attic or attic there is no need to insulate the ceiling. In this case, the increase thermal insulation characteristics rooms are just as necessary as in buildings without an attic, where the warm air escaping outside encounters too weak barriers on its way.

To equip a building without an attic, you can use wax paper, aluminum foil or compacted cardboard, well soaked in drying oil.

For buildings with an attic, the same materials can be used, but most often the ceiling boards on the roof side are coated with clay, and the layer should be about 2 cm. Also today, more modern materials are used:

Vapor barrier is necessary in order to protect the insulation from moisture penetration into its structure. After all, accumulated in thermal insulation layer water will increase the mass of the ceiling system, significantly shorten the service life of the insulation and reduce it quality characteristics.

The higher the air temperature in the room, the more difficult it is to build a barrier to retain heat. To solve this problem, first of all you need to know how warm air leaks from the room:

Application thermal insulation material in a multilayer system it is an excellent barrier to all types of heat leaks. If it is done without violating technology, it will fulfill all the tasks assigned to it. Conversely, making mistakes will lead to the formation of condensation, prolonged heating of the room and greater fuel consumption.

You can insulate the ceiling in a bathhouse with mineral wool, polystyrene foam, expanded clay, sawdust and even earth or clay. Let's consider the options in more detail.

The design of the upper ceiling is almost the same for all types of baths. The load-bearing base is beams that rest on the upper rims made of logs or on the Mauerlat of panel or brick structures. Timber used for construction beam floor, before installation they are treated with antiseptic materials.

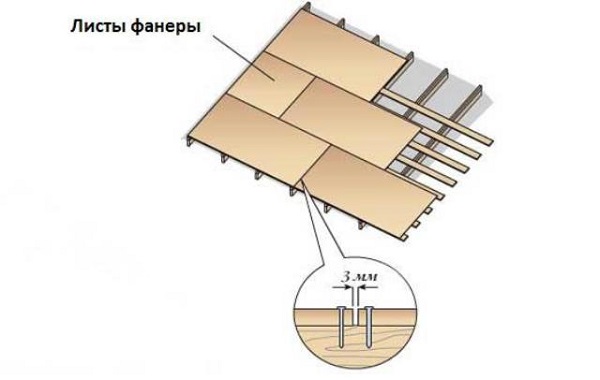

Rolling boards are constructed from low-grade boards. It is very important to make calculations before producing shields. There should be a gap of 5 cm between the beams and shields that will be installed on the skull boards. Between the chimney and wooden elements there should be a distance of 25 cm.

Next, you need to draw a diagram with detailed calculations and configuration of each shield. After the boards are ready, they are numbered so as not to be confused during installation. Shields also need to be treated with antiseptic drugs to extend their service life. A vapor barrier material is attached to the inner walls and bottom of the shield. This can be done using a stapler.

All ready-made designs go up, but without insulation. You need to start with those that will be installed last. After all the elements are raised to the top, they are placed in the required order according to the markings. When all the panels are placed, they are filled with insulation. The gaps formed between the beams and panels should also be insulated. The structure is covered with boards. It is important that the position of the boards is perpendicular to the direction of the beams.

Insulating the ceiling in a steam room is a separate issue, since in this room the ceiling should not only not allow heated air to pass through, but also contribute to the accumulation of steam. It is recommended to lay a double layer of vapor barrier material over the steam rooms, and supplement the ceiling insulation with layers of another heat insulator.