When installing the roof of a private house, a space is formed between the ceilings of the roof and the ceiling of the room, which is called the attic. It can be used as a pantry or arrange a living room or office there. In any case, it is worth paying attention to warming attic space to avoid heat loss and the safety of wooden roofing.

In practice, no construction novelty in the field of insulation, it cannot compete with mineral wool, which has already been proven over the years, which is ideal for insulation country house. Due to the fact that mineral wool is made of solid rocks, its abilities reflect the heat-insulating properties of the stone. meter thickness stone walls replaced brickwork. It has the following characteristics:

The thermal insulation coefficient of the insulation is 0.038–0.045 W / Km, which is a rather low indicator. So the protective layer of mineral wool with a thickness of 100 mm can be compared in terms of thermal insulation with brickwork 1170 mm thick. In this case, the sound insulation coefficient is 0.95 with a maximum value of 1.

Home insulation with fiber insulation meets all requirements fire safety, as it does not burn at all and withstands exposure to high temperatures.

For wooden house Very important indicator is the vapor permeability of the thermal insulation material.

In this case, you can not do without mineral wool. It has good vapor permeability and is used for the installation of ventilated facades. And the last property of cotton wool is its environmental friendliness: the materials used in production do not harmful effects on humans and the environment.

If it is planned to install mineral wool in the attic, then before starting work, you need to decide on its type (glass wool, mineral wool, basalt slabs), density of the material (varies in the range from 30 to 200 kg/m3) and the required quantity.

All this must comply with the requirements for the attic thermal insulation device.

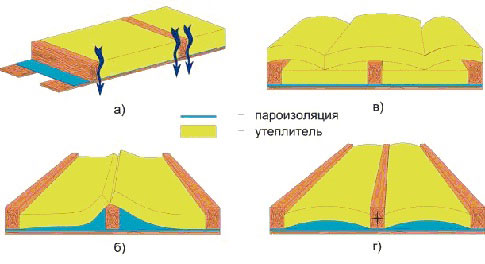

The floor in the attic is also the ceiling of the house, through which heat is lost from the room. moisture from warm air from below constantly penetrates into the attic and exerts negative impact for fiber insulation.

When wet, it loses its thermal insulation properties, and with prolonged exposure to moisture, it quickly collapses. The negative effect of moisture is also noted on structural elements roofs. Condensed water on the inner surface of the roof flows onto the rafters and beams. This leads to the destruction of load-bearing structures.

For guard mineral wool And internal surfaces roofs from water vapor use a vapor barrier made of moisture-proof material. It is placed between the ceiling and the insulation. It is important that no violation of the integrity of the waterproofing is allowed.

To avoid further formation and accumulation of moisture in the attic, ventilation must be properly organized. It is arranged through air vents placed on skates and cornices, as well as through slotted and dormer windows. Ventilation will be sufficiently intense if the ratio of the sum of the areas ventilation holes is from 0.2 to 0.5% of the attic area.

Working with insulating wool requires compliance with safety rules and the use of special PPE. If the attic is not going to be used as living room, then it must be ventilated. Before starting the insulation with mineral wool, ventilation ducts must be installed. They are fastened under the roof with brackets to the roof frame.

If insulation is roll material, then laying the vapor barrier is optional, since the cotton wool is in a polyethylene cover. Strips of mineral wool should be tightly packed, and the edges taped with tape.

In the case of using plates, the insulation is carried out on a pre-laid waterproofing coating.

You need to start warming with cotton wool from the point farthest from the door, gradually moving towards the exit. If obstacles arise, the canvas or sheet must be cut off, and in the next part of the insulation, make a cutout according to the shape of the interference. It cuts great stationery knife. If there are gaps, then they need to be insulated with residues and scraps of material. Try not to be zealous when compacting and bending mineral wool, as this will negatively affect its heat-insulating ability.

If built into the attic floors lighting, then they must be closed with special caps. Although cotton wool does not burn, the device heats up during operation, and conditions for ignition may be created. hardwood floor. Then it remains only to close the thermal insulation by mounting the floor in the attic. It can be plywood, drywall, chipboard or OSB board.

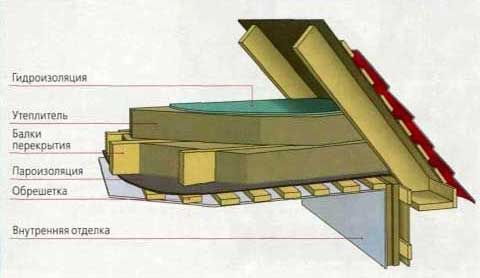

Roof finished attic looks like a puff pastry. The outer cover is roofing material designed to protect the house from rain. From the point of view of thermal insulation, it does not give any effect. The upper waterproofing barrier is a roofing material or special film, which is capable of retaining water, but vapor permeable. It is laid in such a way that water flows through it to the outside. Next comes a layer of insulation, which forms a heat-insulating barrier.

The vapor barrier is designed to completely protect the installed insulation layer from moisture and steam. This polyethylene film is truly completely vapor and waterproof. Everything ends decorative coating to give aesthetic appeal and protection against mechanical damage.

The greatest difficulty in insulating the attic is the installation of a waterproofing layer on a heater of complex shape. The difficulty lies in bypassing all load-bearing elements roof and organization of its exit under the roof for water discharge. It is very important to maintain the integrity of the layer here. Joints and attachment points must be glued with adhesive tape, and between the rafters fastened to brackets or to vertically nailed slats.

The insulation fits tightly between the rafters and, together with the hydrobarrier, is fixed with slats, which will later be a support for finishing. It is recommended to insulate with mineral wool formed into sheets or slabs, as it is more resistant to caking and shedding during operation compared to rolled wool.

As a material for the final decoration of the attic, any sheet material able to protect the insulation from damage. The most commonly used drywall, chipboard or OSB boards, and wooden lining or plastic.

Installation is carried out on rails that fix the thermal insulation on the roof. You can select a separate metal carcass from profiles, but this will require additional space in the attic, and once again violate the tightness of the waterproofing.

Properly installed thermal insulation of the attic will not only help save heat, but also protect the elements of the roof and ceiling from premature aging.

IN winter time the main loss of heat in the room occurs through the main attic floor.

In order to save on heating and prevent the formation of mold on the ceiling, the attic floor should be thoroughly insulated.

Often, insulation is performed from the inside of the ceiling, however, in this case, the size of the room is significantly reduced.

It is best to insulate the attic directly under the main roof.

Wallpaper for finishing the room you can choose on the website www.oboivsaratove.ru

In this case, you should decide on the purpose for which the attic will be used in the future.

If you are going to equip an attic there, then you will have to insulate not only the ceiling, but also the roof. However, if the attic is not a living space, then it is quite enough to insulate only the ceiling.

For warming attic floor any materials can be used, however, the most effective is insulation with mineral wool.

This material has low thermal conductivity and has an extremely a simple circuit installation. In addition, mineral wool practically does not shrink, thanks to which it retains its protective functions throughout the entire service life.

1. Before proceeding with the installation, it is necessary to measure the surface area and calculate the amount of material required. Accurate calculations necessary in order to buy a certain brand in one batch.

2. Also, before starting work, you should take care of your safety. Buy a protective suit, long gloves and a respirator from a specialized store.

The fact is that small fibers of mineral wool, getting into the lungs, cause irritation of the respiratory tract, which is detrimental to health. In direct contact with the skin, mineral wool particles cause severe irritation and discomfort.

In order to avoid such troubles, you should not save on the purchase of workwear.

3. After you have bought the material, you can begin to prepare the surface of the attic floor. Remove all debris from the surface and clean it of dust and other contaminants.

After you finish this stage on the attic floor there should be nothing but necessary tool and insulation rolls of which, for greater convenience, it is better to spread out around the perimeter.

4. Mineral wool is installed between the main ones. First you need to roll out mineral wool rolls on the floor surface.

At the same time, try to lay it so that there are no gaps between the strips of material. If there is a certain obstacle on the ceiling, then it is enough for you to cut an opening in the insulation, and close the gaps that have formed near the obstacle with the remnants of the insulation.

5. Depending on the brand of mineral wool, the manufacturer recommends installing it in two layers. High-quality insulation will be only if, as a result, the layer of mineral wool is not less than 25 centimeters.

When you have completely laid the first layer, take a roll of insulation and roll it over the first layer in the opposite direction. At the same time, carefully ensure that the insulation strips fit snugly against each other.

6. If the attic is not residential, then experts recommend not. It is better that the attic space with insulated ceiling remains ventilated. For this purpose, special gutters made of aluminum profiles are installed on the gates.

7. The last stage of such work is the installation of waterproofing material. It is necessary to cover the entire insulation with such a film and fix it with adhesive tape or a wooden crate.

IMPORTANT! When installing mineral wool, try not to trample it or tamp it when joining the seams. So you can significantly damage the material, which has a low thermal conductivity only due to its porosity.

If you perform such work correctly, then in the next few decades you will not have to think about replacing the insulation. You will notice how much it has become, and at the same time heating costs have decreased.

In this article, we will consider how to properly insulate the attic with mineral wool. We will find out how to take measurements and calculate the need for materials, as well as what tools to choose for the job. But the most interesting is a step-by-step description of the insulation of the attic.

All work consists of separate stages:

The preparatory part of the work consists of the following steps:

| Illustration | Stage description |

| span length is measured. You must know the exact length of the gaps from edge to edge. |

| The width of the gaps and the height of the beams are measured. The width will help us calculate the area that needs to be insulated. The height is needed in order for you to determine whether the insulation will fit into the gaps, or if you have to lay another layer on top of the beams. |

| The area of insulation is calculated. It is important to remember one nuance here - the sheets are cut so that they are slightly wider than the openings and enter them tightly. This makes it possible to achieve quality insulation. After calculating, add another 5-7% to the final result for the difference in size. |

| The thickness of the insulation is determined. Lest you count, I will present the options depending on the lowest temperatures in winter:

Thickness can be more, but not less. |

Shouldn't be trusted project documentation and count everything on it. The actual dimensions very often differ from the design ones, so it is better to spend time and check all the parameters.

To work, you need the following materials:

| Illustration | Stage description |

| insulation. In our case, mineral wool will be used. The material is available both in slabs and in rolls, which one needs to be decided according to the situation. If the thickness of one layer of mineral wool is not enough for thermal insulation, then two-layer insulation is used. |

|

| Vapor barrier material

. To protect the insulation from the formation of condensate, a vapor barrier must be laid on the base. When purchasing material, remember that laps of 100 mm are made at the joints. For additional reliability, it is desirable to glue the joints with adhesive tape. |

| waterproofing film. When insulating a cold attic, it is imperative to close the material on top of the reinforced waterproofing film to protect it from changes in temperature and humidity. It is better to choose reinforced options, they have high strength. |

| Bar for crates. Necessary if the height of the beams is not enough for laying insulation and it is necessary to lay another layer on top. The size is selected in such a way that over stone wool there was a gap of 30-50 mm for ventilation. |

If the rough filing of the attic floor has not been made, then you will need edged board 32 mm thick and self-tapping screws for its fastening.

When doing do-it-yourself work, you will need a tool:

Insulation of the ceiling with mineral wool from the side of the attic is carried out in the following sequence:

| Illustration | Stage description |

| Surface being prepared. Everything superfluous is taken out from the attic, after which you need to sweep the garbage with a broom. Check for protruding nails and other elements that may interfere with work. |

| Vapor barrier is being laid. Insulation of the cold attic floor without this material is prohibited. The membrane is laid on the surface and pressed against the beams, after which it is fixed on them with a stapler. It is not necessary to stretch the material too much so as not to damage it. The photo shows correct option styling. |

| Joints are sealed with tape. Even laps of 100 mm do not guarantee the reliability of the vapor barrier layer. Therefore, they are glued with adhesive tape along the entire length in order to create a continuous barrier to moisture. |

| Mineral wool is cut into pieces right size

. For effective insulation of the attic floor, all elements should adjoin the beams as tightly as possible. Rigid cotton wool is cut 5 mm wider than the opening, and soft wool is cut 10-20 mm wider, best option selected experimentally. |

| A layer of mineral wool is laid. The insulation technology is simple - the elements are placed as tightly as possible, the presence of gaps is unacceptable. If the insulation is narrower than the space between the beams, then it is laid so that as little waste as possible is obtained. |