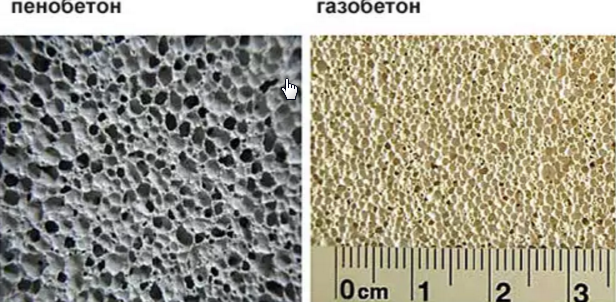

Aerated concrete is one of the types of cellular concrete (along with foam concrete), which is an artificial stone with spherical pores 1-3 mm in diameter evenly distributed throughout the volume. The quality of aerated concrete determines the uniformity of distribution, the equality of volume and the closeness of the pores.

Advantages:

Flaws:

Aerated concrete blocks are intended for masonry external, internal walls and partitions of buildings with a relative humidity of indoor air of not more than 75%. Wall blocks and partitions made of cellular concrete can be used in different climatic zones in the construction of load-bearing structures of residential buildings and public buildings up to 4 floors, as well as for insulation of building structures, bearing walls which are made of colder wall materials(heavy concrete, brick). The main advantages of cellular concrete blocks over other building materials are their lightness, ease of processing (blocks are easily cut and sawn), good thermal insulation characteristics, and Finally, an affordable price.

A distinctive feature of the construction of houses from aerated concrete is the relative simplicity of their construction. No special equipment is needed here. Aerated concrete products are easy to cut, drill and mill. For this, you can use both electrical and hand saws. Holes for sockets and switches are drilled with an ordinary drill, and strobes for wiring are laid manually or using a special nozzle for an electric drill.

Breathable and non-flammable

So, for many years and in many countries, aerated concrete has proved that it is an excellent building material, surpassing traditional brick and wood in some respects. Note that the frequently encountered direct comparison of modern aerated concrete with brick is not entirely correct, given that today the range of "brick" products has been replenished with a number of "novelties" (porous, hollow brick, etc.) with improved properties compared to ordinary brick. Aerated concrete is a material with other properties than bricks and requires the use of other building technologies.

As for the characteristics, due to the porous structure, aerated concrete perfectly retains heat indoors in the cold season and does not release coolness in the hot season. So, a wall of aerated concrete with a thickness of 37.5 cm, depending on the density, has a heat transfer resistance of 2.2-3.5 square meters. m / W ° C, which is unattainable when building walls of the same thickness from denser materials.

Another important property that is observed in aerated concrete is the so-called ability to "breathe", which is characterized by such an indicator as the vapor permeability of the fence. For aerated concrete, this indicator is 0.25-0.22 mg / (m-h-Pa), and for wood and brick, for comparison, respectively, 0.15 mg / (m-h-Pa) and 0.05- 0.1 mg/(m-h-Pa). Thanks to this, aerated concrete is able to perfectly regulate the humidity of the air inside the house, prevent the appearance of mold and fungi. By the way, foam concrete does not have this property due to the fact that it has closed pores.

Aerated concrete is able to withstand heavy loads in axial compression (concrete class in terms of compressive strength of at least B 2.5), which allows the construction of load-bearing walls up to five floors high (up to 20 meters). It also has high frost resistance (at least F35).

While maintaining high strength, aerated concrete blocks have a lower weight compared to other building materials. Thus, the density of aerated concrete is 350-500 kg / cubic meter, expanded clay concrete - 600-800 kg / cubic meter. m, ceramic products 800-1400 kg/cu.m. m, which means that aerated concrete gives less load on the foundation.

In addition, aerated concrete blocks have a fairly large format and an impeccable shape - thanks to this, masonry is quick and easy. Accordingly, the labor costs are many times less than in the construction of bricks.

It is important that aerated concrete is an inorganic material that belongs to the category of non-combustible building materials. It is able to withstand one-sided exposure to fire for 3-7 hours and protect metal constructions from direct exposure to fire. Numerous tests have shown that when the temperature rises to 400°C, the strength of aerated concrete increases by 85%, with a further increase in temperature to 700°C, the strength decreases to its original value. The structure of the aerated concrete building after the fire remains unchanged.

Easy to work

Due to their structure, aerated concrete blocks are easily and accurately processed (sawed, drilled, milled), which makes it possible to realize almost any architectural solutions. Need a 28 degree turn? Protractor, pencil, saw - and a block with an angle between the faces of 28 degrees is ready in 30-40 seconds.

Because the limit deviations geometric dimensions"aerated" products in height and thickness are only 1 mm, the masonry is carried out using an adhesive solution with a thickness of only 1-2 mm, which ensures adhesion and eliminates the presence of so-called "cold bridges" in the masonry. (Despite the fact that the use of cement mortar leads to an increase in the complexity of work and consumption of materials, and thick mortar joints form "cold bridges" that increase total heat loss through walls by 10-30% depending on the thickness of the joints.)

The process of building walls from blocks does not require the involvement of special equipment to move them on the site. All work on the construction of the house can be completed in one season (aerated concrete practically does not shrink), while there is no need to use complex and expensive tools, it is enough to have a bucket for preparing an adhesive solution, a notched trowel or a ladle for applying glue, a hacksaw with a large tooth for sawing blocks in place, large emery to eliminate irregularities, a sweeping brush. On construction site aerated concrete comes in the form of building blocks laid and fixed on a pallet, the laying of which is similar to assembling a designer from prefabricated elements. Depending on the needs of the construction, a wide variety of aerated concrete blocks are produced, which differ in strength, size and shape. The material can be used both for the construction of load-bearing walls, non-bearing external walls and internal partitions, and for the thermal insulation of roofs and floors.

During the construction of an average country cottage aerated concrete blocks with a density of 400-500 kg / cu. m with optimal characteristics of strength and weight.

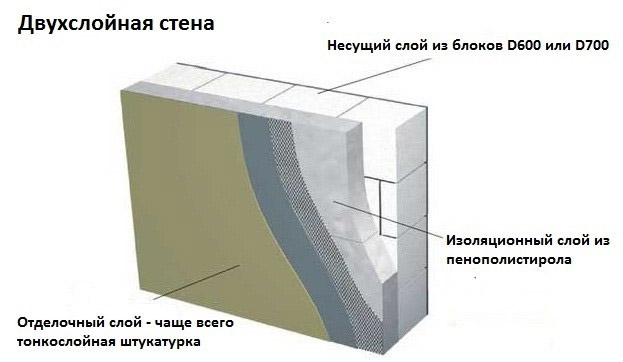

The relatively high water absorption of aerated concrete should be taken into account. To increase the durability and improve the operational characteristics of aerated concrete, various ways exterior finish, which, protecting it from external influences, should not prevent the diffusion of water vapor from the premises to the outside. So several methods are considered ideal finishes: any hinged ventilated facades with decorative panels, siding, lining, facing bricks with the obligatory leaving of an air (preferably ventilated) gap of 30-40 mm between brick and block masonry; thin-layer plaster for aerated concrete; grout seams between blocks, followed by painting with textured vapor-permeable paints.

Most individual developers focus on modern varieties artificial stone, preferring them to traditional wood or brick. With all the nuances of the construction and operation of houses made of aerated concrete, their pros and cons should be dealt with in detail. main reason- in the lack of awareness of the potential buyer and often diametrically opposed opinions about the feasibility of such construction.

So is it worth it or not to use aerated concrete blocks for a residential building? Where is the truth and where is the lie about this material? What hidden problems of aerated concrete are “shyly” silent about by manufacturers and sellers? We will draw our conclusions on the analysis of the numerous reviews of the owners who already live in these houses.

The main reason for the ambiguity in the assessment of aerated concrete is ignorance of the specifics of its production and use. Before finding out what this building material has more - pluses or minuses - one should clarify not only with its characteristics, but also with the terminology.

Aerated concrete is the generalized name for two types of cellular concrete, and both are used in the construction of houses. In most cases, due to a misunderstanding of the features of their production technology, the shortcomings of one are often attributed to the other. The basis of aerated concrete is cement, such a stone for the house can be distinguished by its grayish color. In the composition of the initial gas silicate mixture, lime plays the role of a binder. Gas blocks of this type are white.

The fundamental difference is in the manufacturing technology. Aerated concrete products can be produced independently, at home, that is, at the place of work. But his "brother" - only processing in autoclaves (pressure and temperature) with further transportation to the consumer. Since the price last version the material is slightly higher, in the private sector, in the construction of residential buildings and other buildings, aerated concrete is more often used. Here, further emphasis will be placed on it, especially since the difference in the pros and cons of stones for most parameters is not so significant.

1. Benefits.

This property of the material greatly simplifies the construction of a house.

Firstly, the gas block does not crumble when cutting, while for an analog made of foam concrete this is one of the main disadvantages.

Second, installation (fixing) attachments in the house is no problem. In this regard, gas blocks are not much inferior to bricks. With regard to foam concrete, fixing something on the wall of the house is much more difficult - only on the anchor. And this is not always convenient, since reinforcement of the base is often required, otherwise the weight suspended structure is sharply limited.

Thirdly, the construction of a house from aerated concrete can be carried out in several floors, but from foam blocks - no more than two.

The strict geometry of gas blocks facilitates their fitting in place. The seams are so insignificant that the influence of "cold bridges", judging by the reviews of the owners, has practically no effect on the microclimate in the house.

Simply put - such a house retains heat well. If we take into account the constant growth of energy tariffs, this is another plus, and not a small one. According to the reviews of the owners of houses, the cost of heating them is much less compared to buildings made of brick and, moreover, reinforced concrete products.

Given that the cost of building a foundation is approximately ⅓ of the estimate, at this stage you can save a lot. More than a significant plus of such a house.

Gas blocks have significant dimensions. Even if you buy the smallest ones, then building the walls of the house from them will turn out much faster than from brick or wood.

A house made of aerated concrete blocks is rightfully considered one of the best options for solving the housing problem. Regardless of whether it is being built on its own, or purchased, such construction belongs to the "budget" category.

2. Disadvantages of aerated concrete.

Judging by the reviews of homeowners on thematic forums, increased moisture absorption is practically the only disadvantage of this stone. But here, too, not everything is clear, since this shortcoming aerated concrete blocks are somewhat relative.

Firstly, residential buildings one way or another outside are made out. For example, if it is necessary to insulate a building, which is done almost everywhere for our climate. Plus - waterproofing the house. Therefore, lining is mandatory.

Secondly, such a minus of a house made of gas blocks is canceled if overhangs, window drains, and a drainage system are thought out and correctly installed.

Thirdly, a lot depends on the technology used to make the stone. A house made of autoclaved aerated concrete has the best performance characteristics. It has a higher density, which means that it absorbs moisture less intensively.

“I was engaged in building a house on my own, without the help of specialists. I believe that all the disadvantages of aerated concrete products are attributed to those who in practice have not dealt with this material, but judge it only by the reviews of the same "experts". My opinion is unambiguous - subject to the technology in such a house, high performance characteristics and an acceptable cost are optimally combined. I've been living in it for the 5th year, and so far no complaints. What’s more, heating costs are significantly lower than when my family and I huddled in an old brick building.”

“I was engaged in building a house on my own, without the help of specialists. I believe that all the disadvantages of aerated concrete products are attributed to those who in practice have not dealt with this material, but judge it only by the reviews of the same "experts". My opinion is unambiguous - subject to the technology in such a house, high performance characteristics and an acceptable cost are optimally combined. I've been living in it for the 5th year, and so far no complaints. What’s more, heating costs are significantly lower than when my family and I huddled in an old brick building.”

Vladimir Olshansky, Moscow region.

“I know firsthand about houses made of aerated concrete. I work as a foreman, so I built a lot of this stone and I can give my opinion. The pros of gas blocks are much greater than the cons. When ordering houses (without interior decoration) turnkey in a couple of months the box is completely ready. Another advantage is that there is no need to wait for shrinkage. Therefore, it is possible to partially begin to settle down in parallel with construction. Diversity finished projects houses made of aerated concrete makes them accessible to all segments of the population. For families with very modest incomes - a good option. I don’t think there are any significant shortcomings in gas blocks.”

“I know firsthand about houses made of aerated concrete. I work as a foreman, so I built a lot of this stone and I can give my opinion. The pros of gas blocks are much greater than the cons. When ordering houses (without interior decoration) turnkey in a couple of months the box is completely ready. Another advantage is that there is no need to wait for shrinkage. Therefore, it is possible to partially begin to settle down in parallel with construction. Diversity finished projects houses made of aerated concrete makes them accessible to all segments of the population. For families with very modest incomes - a good option. I don’t think there are any significant shortcomings in gas blocks.”

Ilya Zotov, Moscow.

“I am rather skeptical about various reviews, reviews posted in the media. It's no secret that most of them are made to order. When I bought a building plot, I just took it and walked around the neighborhood, asked the neighbors' opinion about their houses. Personal communication with people made it possible to conclude that for me, given the material possibilities and limited time, The best decision- to build a dwelling from aerated concrete blocks. The house turned out to be solid, and now, having lived in it for 3 years, I can say that I was not mistaken. I think that those who want to build both inexpensively and with high quality should pay attention to aerated concrete.”

“I am rather skeptical about various reviews, reviews posted in the media. It's no secret that most of them are made to order. When I bought a building plot, I just took it and walked around the neighborhood, asked the neighbors' opinion about their houses. Personal communication with people made it possible to conclude that for me, given the material possibilities and limited time, The best decision- to build a dwelling from aerated concrete blocks. The house turned out to be solid, and now, having lived in it for 3 years, I can say that I was not mistaken. I think that those who want to build both inexpensively and with high quality should pay attention to aerated concrete.”

Sergey, Samara.

“When I started to build a house, I decided that if I save money, then just not on the project. No matter how attractive aerated concrete is, it is still “foam”. Experts helped and optimal thickness pick up blocks, and finishing materials. If everything is done correctly, then a house made of such a stone will last a long time. Nevertheless, without taking into account all the features, I would not recommend anyone to build. First of all, you need a timing. If you leave the box at home for the winter, then there will be so many problems that the final cost will simply go off scale. Therefore, "amateur" has its limits.

“When I started to build a house, I decided that if I save money, then just not on the project. No matter how attractive aerated concrete is, it is still “foam”. Experts helped and optimal thickness pick up blocks, and finishing materials. If everything is done correctly, then a house made of such a stone will last a long time. Nevertheless, without taking into account all the features, I would not recommend anyone to build. First of all, you need a timing. If you leave the box at home for the winter, then there will be so many problems that the final cost will simply go off scale. Therefore, "amateur" has its limits.

Oleg, Omsk.

“I think that the approach to the use of gas blocks should be professional. We must not forget about the cellular structure of the stone, and therefore the disadvantages - moisture absorption and fragility. When building a house, it is necessary to reasonably combine aerated concrete masonry with brick, reinforcement, quality finish. Those who believe that this material is a "gift of fate" are mistaken. There are certain difficulties, so it is better not to start building a house without consulting a specialist. The cost of gas blocks will justify itself only if the technology of working with them is strictly observed.

“I think that the approach to the use of gas blocks should be professional. We must not forget about the cellular structure of the stone, and therefore the disadvantages - moisture absorption and fragility. When building a house, it is necessary to reasonably combine aerated concrete masonry with brick, reinforcement, quality finish. Those who believe that this material is a "gift of fate" are mistaken. There are certain difficulties, so it is better not to start building a house without consulting a specialist. The cost of gas blocks will justify itself only if the technology of working with them is strictly observed.

Ivan Pershin, Krasnoyarsk.

conclusions

The fact that aerated concrete has much more pluses than minuses is obvious. But if there is a choice alternatives for the home, then when is it more expedient to make it in favor of this material?

1. When limited free space Location on. Gas blocks are planted on glue, so it is not necessary to prepare a solution.

2. If a house is being built with 2-3 floors, foam concrete is clearly not suitable.

3. If you want to partially save on home insulation. In some cases, it is enough to correctly determine the thickness of the gas blocks.

4. If it is impossible to equip a massive foundation. For example, if the soil on the site is problematic.

To take into account all the nuances is unrealistic. But the information given in the article is enough for the dear reader to decide for himself whether to build a house (or not) for him from aerated concrete. In any case - success!

Each manufacturer of this popular building material is confident in its products, at least when it comes to sales. But any construction forum contains entire message threads, where a dissatisfied buyer describes in detail the positive and negative characteristics of an aerated concrete block.

Why this universal material not perfect? We will analyze the minuses, pluses, features for specific buildings and much more further.

Let's start with the positive:

Let's end with a negative:

According to SNiPs, from 5 to 12 percent is permissible for this building material. It turns out that at the maximum indicator, the thickness is no longer 40 cm, but not less than 54 cm. They like to keep quiet about this.

Clearly about the pros and cons in the video:

Let's start with prices:

Brick (ceramics) from 10r apiece. It's 5000 per cubic meter.

Brick (pores) from 19r apiece. It's 4500 per cubic meter.

Aerated concrete (classic 200x300x600) from 104 rubles apiece. For a cube only 2900-3000 thousand rubles.

Bottom line: aerated concrete is twice cheaper.

Comparison of technical characteristics:

Let's put it in simple terms:

For prices:

Let's start with living quarters.

Each owner of a residential building, who has evaluated the overall design of the building, will say positively about aerated concrete:

From the negative or shortcomings:

Developer advice! Under a residential building, an exclusively autoclaved block is purchased, a thickness of 300 mm is sufficient. But internal insulation and a reinforced belt are mandatory elements.

Otherwise, the roof will unevenly push through the walls, cracks will appear, and all this will affect durability and heat retention.

Of the really convenient qualities are:

About the disadvantages and disadvantages:

Which house is better, aerated concrete or brick?

Best of all, of course, symbiosis, so to speak. The inner part is gas-concrete, the outer part is a facing brick.

But the most expensive thing in a private house is the foundation. It turns out that the buildings are purely made of brick, of course not worse, but much more expensive, three times.

Building walls of aerated concrete and finishing there is a big mistake. Necessarily expensive lining is needed, but with a foundation it is easier.

What are the pros and cons of autoclaved aerated concrete?

An important disadvantage is the price. Usually a cubic meter of autoclave costs a thousand more!

But an important plus is that additional thermal insulation is not needed over the entire area of \u200b\u200bthe walls. This is significant!

Pros and cons of load-bearing walls made of aerated concrete?

Due to the high porosity, the bearing properties of the material are reduced. Without reinforced concrete reinforced belt Don't start building!

The question is not simple. In the video below, Alexander Matveev makes an attempt to give a definitive answer to it. The analysis cannot be denied content, but judging by the number of comments and dislikes, it is impossible to put an end to the debate on this topic.

The process of buying aerated concrete is not complicated, but it requires certain knowledge that will help you not to buy too much and distinguish a high-quality product from a fake, or you can trust one of the many companies on the building materials market in Moscow and the Moscow region. Knowing where and how, you will definitely get a worthy product that will last a long time.

Start industrial production Autoclaved cellular concretes were laid by Siporex (Sweden) in 1929.

Cellular concrete began to be used in Russia in the 50-60s. In Moscow and the Baltic States, there were entire institutes developing new technologies for its production.

By appointment, aerated concrete blocks are divided into:

By density, aerated concrete is divided into:

Currently, the most optimal and popular brands are blocks with a density of 400-500 kg / cu. m.

To build a house with bearing capacity and at the same time good thermal insulation characteristics, you must select the brand D500. This brand allows you to build houses on 3 floors with floor slabs between floors.

Today in Moscow and the region there are more than 10 factories producing this species products. Factories are fairly evenly distributed throughout the region. All these factories produce products according to GOST 2007, that is, the quality of products is approximately the same. Consequently, the price comes to the fore, which is influenced by a number of factors: raw materials, the remoteness of the plant from the construction site, and the manager's competence factor. When buying aerated concrete blocks, you need to understand some aspects: imagine what you want to build, how wide the wall should be. To a lesser extent, the height of the blocks has an effect. The length of the blocks: 500, 600 or 625 mm, is practically not important, because the last block is sawn in the masonry. The number of cubic meters that you need to build your object does not depend on the length and height of the blocks. The width of the block, that is, the width of the wall of the future house, has a direct value. So, with a wall thickness of 250 mm (we take it as a base value) at a house of 10x10 meters and a height of 6 meters, about 60 m3 will be needed to build a monolithic box, and with a wall width of 300 mm, already 72 m3, etc. As a rule, 10-15% is deducted from these values for windows and doors, depending on the project. We do not consider internal load-bearing walls and partitions, they occupy 20-30% of the total outer wall. You can, of course, read a lot of reviews, but, as a rule, negative ones can be found on each manufacturer. It's simple, if the plant makes an average of 300-400 thousand m3 of gas blocks per year, then it sells them. The number of negative reviews on the Internet is a drop in the ocean. If you were brought good block, then in most cases you will not write about it - this is normal!

This article is based on practical knowledge. Some employees of our company have been working for more than 5 years at one of the plants producing aerated concrete blocks, located in the Moscow region.