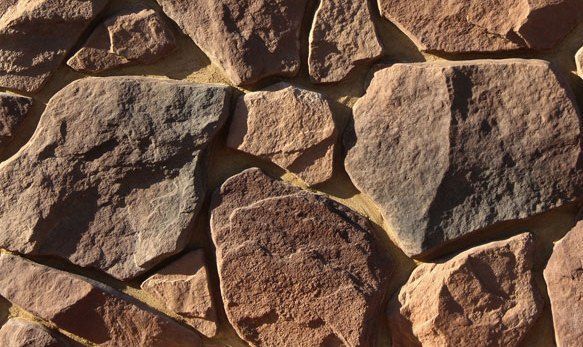

plinth trim natural stone considered the most popular. All this for the reason that the material has a very attractive appearance and excellent technical characteristics.

Facing the basement of a house with natural stone can be done using:

Let's take a closer look:

Advice. In order for the shell rock to serve as a finish for a long time, its surface must be covered with a protective layer. Use a special primer or a simple varnish for this.

Advice. Facing the basement with wild stone can also be performed by other breeds that are of natural origin. The most important thing is that the material be extracted in those regions that, in terms of climate, will be similar to the climate of the region in which the house is being built.

Advice. In the decoration of the house, marble slabs are very often used, only in outdoor decoration it is not recommended to use such material, since in some regions its structure may be subject to deformation and for this reason the external design of the building will be damaged.

The first thing you need to focus on is the budget for finishing. If it is not too large, then you can use shell rock or sandstone. Quartzite also belongs to the economy category. If the amount allows, then you can choose a more attractive granite.

Further:

Advice. When choosing a natural stone, you must definitely ask the seller for certification documents that indicate that the stone does not emit radiation and is of natural origin.

For facing the basement of a house, it has the main property - environmental friendliness. It will not harm human health and the environment.

It is very durable and reliable. On its surface, it can withstand almost any load. All this is due to a very dense structure.

Features and Benefits:

Advice. To finish the plinth, in addition to natural stone, you can use artificial, which in appearance is no different from natural, only it costs several times lower.

Natural stone has several types of surface that have an original appearance and everyone is popular.

Surface:

Advice. When choosing a natural stone surface, it is worth considering how easy and fast it will be cleaned. If there are a lot of different recesses on the surface, and the color of the material is light, then it is better not to use it for facing the base.

Facade plinth cladding with natural stone can be combined with any other finishing material on the wall surface.

The most common option is plastered walls with natural stone on the plinth. Very often you can find natural agglomerate on the base, and on the walls - fake diamond.

So:

Advice. Plastic lining for finishing a building using natural stone on the basement, it is not recommended to use it, since the house will not look aesthetically pleasing.

The photo shows various options decoration of the building with natural stone on the plinth.

The plinth, as a rule, is built of red refractory bricks. It has excellent strength and can withstand heavy loads.

And natural for the base has a very large weight and for other surfaces it will be mandatory to strengthen them.

The next step is to level the surface:

Advice. If a brickwork made evenly and there are no deposits on the surface concrete mortar, then you do not need to level the surface either.

Advice. To make the solution stronger and with a denser structure, it is necessary to use proportions of 1 to 2 or 1 to 1.

To apply the solution to the surface, a spatula and trowels are used. All work is carried out according to the type of work with plaster, only upon completion does not apply sandpaper, since concrete is not subjected to this type of impact.

It will not be difficult to do the installation of natural agglomerate on the surface with your own hands.

For them you will need:

Advice. Special glue is not used when fixing natural stone, as it does not have high strength after drying.

The concrete solution has a gray tint, which is not suitable for every stone design. It is for this reason that you can add a coloring pigment to it and give it a different color.

The video shows an example of the installation of natural stone in slabs on the surface of the plinth.

The company LLC "Art-Kamen" offers for sale on favorable conditions artificial stone for plinth. It has the same colors, shapes and reliefs, and even traces of time on the surface, that is, it completely imitates natural stone. Like millennia ago modern man would like to have one too stone house. However, at the same time, he faces problems, since natural stone is very heavy and fragile, and its transportation is expensive, and it is almost impossible to select the required amount of material of the same texture and color. But do not give up on your dream, because thanks to the latest technology you can easily make it come true.

However, when comparing the finishing stone for the plinth with the original, you can see that the artificial stone is several times lighter, much easier to transport and much easier to work with. To finish the house, you do not need the backbreaking work of builders and heaps of heavy stones. The process of laying artificial stone for a plinth is no more complicated than laying ceramic tiles.

We bring to your attention affordable, environmentally friendly, lightweight, easy to install and having a wide color scheme finishing material - plinth stone. Traditionally, it is used in the lining of the basement to protect the walls from adverse external climatic phenomena. However, the decision on the fragmentary use of artificial stone on the facade, as well as the combination of several of its colors of the same texture or several textures of the same color, is interesting.

Pay attention to a curious fact: a house lined with artificial stone costs 10% more expensive than home finished with a finishing facing brick, and at the same time laying an artificial basement stone is much cheaper. Based on this, we can say with confidence that artificial stone is a profitable investment.

The plinth stone sold by our company is a guarantee of high quality. The product meets all the requirements technical specifications, certified, at each stage of production quality control and compliance with the latest technologies manufacturing.

Stone for facing the lower part of the facade has been used since ancient times. And despite the fact that today a large number of modern materials, this type of finish is widely in demand to this day. This material is attractive in appearance and practical in operation. This article will describe in detail the main properties of natural and artificial stones, as well as the process of lining the basement with these stones.

Before choosing and purchasing a material, you should figure out for what purposes the finishing of the lower part of the facade is performed, and what functions it will need to perform. Finishing the plinth is not only about appearance, it also implies a lot of useful functions for the building. Thanks to the finishing of the basement, the foundation of the building becomes waterproofed. The finish determines the formation of the dew point. This is a very important point. The waterproofness of the basement determines the percentage of humidity both in the basement and in the entire building as a whole.

So, finishing the lower area of the facade of the building with stone:

Attention! During the finishing of the building, it is necessary to remember about the blind area. It increases the life of the finish, and also carries a large number of other positive properties.

There are two types of stone - artificial and natural (natural).

Artificial stone for plinth cladding is used much more often than natural stone, and this is due to the following reasons:

Natural stone has several main advantages. Its main advantage is that it is absolutely eco-friendly material. Natural stone does not have a harmful effect on the human body and is completely safe. Also, natural stone has high strength, perfectly tolerates any weather, enduring to loads and abrasion, and is also not afraid of interaction with acids.

A plinth made of natural material is offered at a fairly high price compared to artificial, it is much heavier and therefore more difficult to install.

For facing the lower part of the foundation, you should choose a dense and frost-resistant natural stone. As practice shows, dark-colored stones are often used. The basement of the building is most exposed to various adverse factors: contact with moisture and dirt, temperature changes. Finishing the lower area of the foundation must withstand all of the above phenomena for many years.

According to its characteristics, natural stone of the igneous type - granite, labradorite, gabbro, etc. - can best cope with this task. In addition, quartzite and sandstone are often preferred. dark shade. No need to use marble stone to finish the lower part of the facade of the building - after a couple of years it will lose its original appearance.

Choosing a natural stone, you must be as careful as possible in the process of sealing the seams.

Table 1. Comparative properties of GRANITANE, concrete, natural stone

| Variety of material | Ultimate compressive strength, MPa | Bending strength, MPa | Water absorption is not higher than % | Water permeability, MPa | Acid resistance, % | Frost resistance, cycles | Abrasion, % |

|---|---|---|---|---|---|---|---|

| Acid-resistant tiles | 50,40 | 25,15 | 3,5/4,5 | 97/96 | |||

| Acid-resistant brick | 55/50/35 | 6/6.8.8 | 97.5/97.5/96 | ||||

| Heat resistant concrete | 50 | 0.8 | 75 | ||||

| Chemical-resistant concrete | 30-50 | 6 | 87 | 80-100 | 0.4 | ||

| Hydrotechnical concrete | 30-50 | 4-3.5 | 6 | 0.8 | 300 | 0.7 | |

| natural granite | 100 | 15 | 0.15-0.48 | 97-100 | >800 | 0.5 | |

| 120 | >18 | 1.5-3.0 | 1.2-3.0 | 97-100 | 1200 | 0.18-0.2 |

This type of stone is selected primarily in accordance with the intended overall design. However, there are some General requirements, which should be observed when working with granite and marble. So, building standards state the following: facing elements, including socle natural stones, with an area of up to 0.4 square meters and up to 10 mm thick, can be laid on cement mixture or special glue without the use of additional fasteners. Masonry elements larger area and thickness is carried out using fasteners.

The main limitation in the process of choosing natural stone for finishing the lower part of the facade of the building is the incompatibility of silicate rocks (quartzite, sandstone) with carbonate rocks (dolomite, marble, shell rock). If materials of different rocks are nearby during the masonry process, then the silicic acid that silicates have will begin to react with calcium carbonate, which is the basis for limestone rocks. Ultimately, due to the resulting reaction, both rocks will be destroyed. Other types of stones natural material can be stacked with each other, interaction will not bring significant damage.

![]()

In the process of work, there is one nuance - the laying of stone is carried out with a decent gap, since natural material can change in volume depending on the weather and temperature, and each breed has its own individual characteristics in this plan. The gap size is calculated based on the size of the granite or marble slabs and the density of the natural stone.

If the work on facing the lower part of the facade of the building is carried out using several types of stone, then the gaps are calculated for the material that is characterized by a higher coefficient of increase in its volumes.

Finishing work on the basement floor, using artificial or natural material, is carried out according to strict rules and according to the appropriate scheme. All of the steps below are extremely important and should be followed as described. Any non-compliance with the rules will lead to a decrease in the effectiveness of the work done.

To the first stage of preparation for finishing ground floors artificial or natural stone should be approached very seriously, since the durability and quality of the structure as a whole depend on it.

Attention! Before starting this work, it is necessary to assess the condition of your foundation (its strength, durability), it would be useful to invite a specialist to determine whether the base can withstand the weight of the finishing material. Artificial stone is not heavy, but natural stone, on the contrary, has more weight.

Step one. Initially, it is necessary to make the lower area of \u200b\u200bthe facade as clean as possible, completely removing the remnants of dirt and previous materials. To do this, it is better to use a metal brush. If the old plaster is very strong and this tool cannot handle it, you can do this job with a chisel and hammer.

Step two. After completing the cleaning, you will need to make the so-called "notches" on the base using an ax. This procedure can be omitted if the seam is deepened by 1 centimeter - this option will be more effective and will double the adhesion of the surfaces.

Step three. Further, the working surface is treated with a primer. Her choice must be approached responsibly and only purchase a primer deep penetration. The liquid is applied with a spray gun or brush.

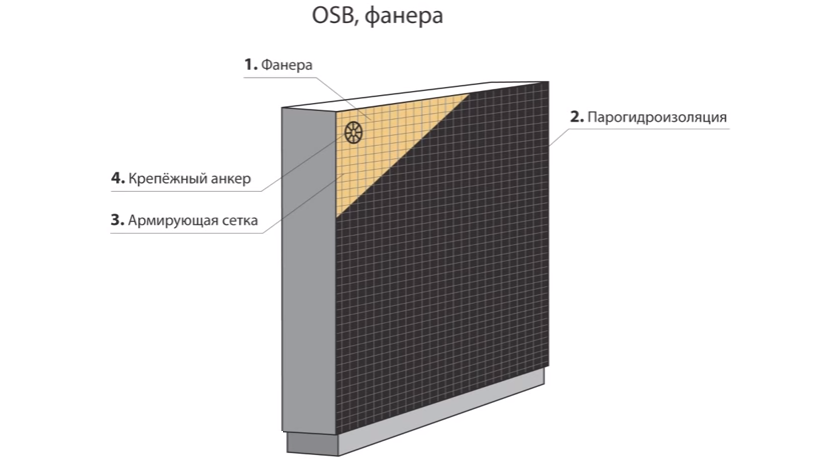

Step four. If the surface has a heterogeneous composition, you will need to fix on it construction grid, thanks to which, the connection of surfaces will be stronger. The mesh is fastened with anchors, which are hammered into the pre- drilled holes in the foundation.

Attention! If you plan to use a building mesh, you should not lay stone on it. First you need to "throw" the cement mixture on the surface. A ladle is suitable for this - no need to "pour" building mixture, it is important to do exactly the spray, then let it dry.

Sketch of the mixture on the chain-link mesh

After applying and leveling the spray, prime the surface again.

Further, in order for the work to be completed correctly, it will be required define the installation line. Regarding the building, the ground surface is not ideally flat in all places. To do this, you need to draw a strict installation line. This mainly affects the exterior of the building.

Step one. We set the risk in the area where the work will be performed.

Step two. Then it must be distributed on all other walls. The ideal tool for this is a hydraulic level, which can be purchased at any hardware store, also, it is not difficult to make it yourself. It is he who will allow you to complete this step correctly.

step three. After installing all the risks, they will need to be connected. This will help the usual nylon thread. All the risks entwined with it form a line, which was needed to start finishing works.

step four. We fix starting profile using dowels. Such a bar will not allow the finish to “move out” below the marked line.

It is important to prepare the tools before starting the lining, so as not to waste time during the masonry process looking for it. So, for work you will need the following tools:

The cladding of the lower area of the facade will be done with high quality strictly at positive temperatures. Although there are sweeps that allow you to do this procedure and with negative temperature, their service life will not be so long. The masonry mortar largely determines the appearance and durability of the structure. Its correct manufacture will ensure high-quality and fast finishing. Although modern market and offers various adhesives and compositions, a cement mixture is often used.

Attention! Heat, more than 23 degrees, will also adversely affect the workflow. In the heat, moisture evaporates very quickly from the solution - the adhesion will be short-lived.

Step one. First you need to pick up a container for making a batch. Do not use a container with uneven edges and bottom.

step two. We fill the container with cement and then with sand in accordance with the proportion of 3 to 1 (for M300).

Step three. By mixing, we obtain a dry homogeneous composition.

Step four. We add some water.

Pour the dry ingredients into a bowl of water. Using an electric drill with a nozzle, mix the mixture. Worth adding water in small portions. In the process of mixing, it will become clear whether you need to add more or whether it is already worth stopping. The mass should not be liquid.

Attention! If you make a solution not with mountain sand, but with river sand, the mixture will settle. To prevent shrinkage, you should add a little of any laundry detergent.

There are two types of masonry: seam and seamless. In the first, frequently used type, the correctness of the seam and the correct laying of the stone are important. The second type is much simpler than the first, here you only need to choose the right cut parts of the stones.

![]()

Step one. The beginning of the masonry occurs from the corner of the building. Each row must be tied. This is not difficult to do, you just need to exclude the coincidence of the seam when ordering.

Step two. An important requirement when laying stone (namely tiles of the correct geometric shape) is the constant use of the level. The laying of each row should be checked. It is necessary to achieve perfectly even masonry, only after that begin work on the next level.

Step three. We apply the previously mixed composition to the stone and lean it in the required area on the wall, press down. We carry out small rotational movements, which will evenly distribute the cement composition and will not allow empty space to form in the masonry. In some cases, for effective shrinkage, you can use a rubber mallet.

Step four. The seam line should be correct, that is, even, the template will help with this.

Step five. During laying, it is necessary to focus on the finishing of the corners, which must be done without any deviations. With the help of a plumb line, deviations in the fastening of the stone are revealed.

Step six. First you need to lay two stones at the corners of the building. Next, you need to stretch a nylon thread from the top of the stones, with which you can mark for yourself a strict attachment line for the rest of the stones. All discrepancies will be immediately visible.

Step seven. The lining of the basement will be correct if the stone is divided by the grinder into the required parts. The cut off part is first “tried on” in its place, if everything matches correctly, a solution is applied to it and the stone is pressed against the wall surface.

Step eight. By the same principle, the laying of the basement stone is carried out along the entire wall.

Step nine. The next thing to do after finishing laying the stone is to rub the seams.

The final part of the plinth lining with stone is the grouting of the joints formed.

When the composition connecting the surfaces dries up (up to three days), you can begin to overwrite the seams. This process cannot be skipped in any way, since through the empty areas left in the seams, moisture penetrates under the facing surface, destroying the entire structure. To wipe the seams, a variety of compounds are used to fill the gaps. As tools for work, a trowel or a wide metal spatula is perfect. It is very convenient to apply the solution into the seams from a syringe.

In order for the gaps to be filled evenly and beautifully, it is necessary to produce jointing. Ideal for this job, not only special tool, but also a rubber cable of the required thickness, which is embedded in a still raw solution.

After the grout dries, all its excess is removed with a coarse brush. On the first day, the area where the grouting took place must be reliably protected from moisture. Also, the finishing surface must be protected from direct sun rays and frost for at least seven days. 24 hours after the grouting procedure, the surface can be wiped with a cloth soaked in water.

The modern market offers a wide variety of different grout compositions: frost-resistant, elastic, and others. There are also sweep different colors. To give the plinth natural look after finishing, it is necessary to choose a grout mixture of the same tone as the stone itself.

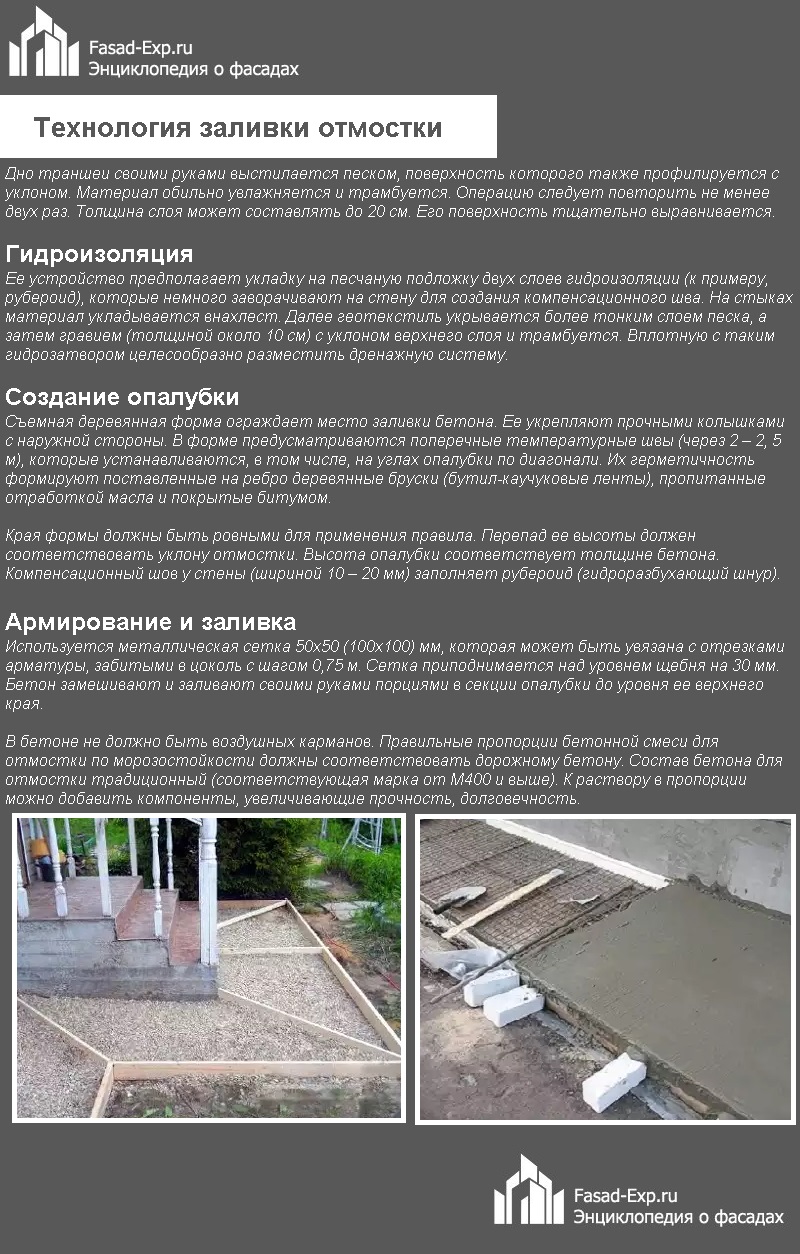

The blind area is a must structural element. Finishing the lower part of the foundation will be unfinished without it.

The blind area protects the basement area from the effects of natural factors, and prevents the penetration of moisture into the foundation, as a result of which the shrinkage of the building becomes more uniform.

The width of the blind area depends on the height of the placement of the cornice overhangs. Also, this value is also affected by the degree of planting. land plot. If it is not so big, then the blind area should be more massive. It must be remembered that the width of the blind area should not be less than 60 centimeters.

The work is carried out as follows.

Step one. Initially, we make formwork from unnecessary boards, which should be sprinkled with earth or reinforced with pegs so that the solution does not flow over the sides.

Step two. We fill the formwork with rubble, you can also use any stones that are aimlessly on the site.

Step three. We make cement mortar. It must be liquid enough to completely fill the contents of the formwork.

step four. After completing the filling and leveling, leave the formwork until the solution has completely dried.

Now we give the finished look to the blind area, filling the entire surface with gravel. It is also necessary during rain - splashes will not fall on the base.

To further protect the natural stone plinth from moisture penetration, it is recommended to cover it with a colorless moisture-resistant varnish. If you have done everything according to these instructions, original finish plinth will please your eye for many years.

The use of natural stone in decorative cladding the socle gives a solid look, the completeness of the appearance of the building. The material justifies the effort and money spent. Do-it-yourself stone finishing significantly reduces the cost of facing.

Facing the plinth with stone is not only beautiful, but also practical

Facing the plinth with stone is not only beautiful, but also practical

Details of facing the basement of the house from natural materials(namely, a stone) are a symbol of reliability and comfort for a number of their qualities:

Preferred dark tones plinth. They rarely need cleaning from dust, drips, dirt.

Frost resistance, the density of the stone characterizes the resistance of the finish to the destructive effects of nature, a large number of cycles. For the basement of the house, this is especially important.

At the moment, there are many types of finishing stone for every taste.

At the moment, there are many types of finishing stone for every taste.

According to a number of characteristics, natural stones of igneous origin are chosen for such a task - gabbro, granite, labradorite, dolomite, shungite, lemesite. Sandstone and quartzite (dark) are widespread.

Harvested natural wild mineral can be pre-treated, be as it is - unprocessed. Without processing, the pieces are supplied in the form of a layer, cobblestone, pebbles. Large gaps are filled with pebbles, achieving a uniform thickness of the seam between large parts, including other rocks.

An unusual effect is created by combining tiles and strips

An unusual effect is created by combining tiles and strips According to the form obtained as a result of processing, there are:

Any prepared natural veneer at home significantly speeds up the installation work.

The outer section of the front part according to the degree of processing is:

The most commonly used tiles are 20x20 cm or more

The most commonly used tiles are 20x20 cm or more

Stone for decoration can be of various sizes. For ease of installation, it is made in the form of plates, blocks. One fragment is 0.2-0.5 m, thickness - from 1 cm. Obtaining smaller parts, shape changes are achieved with a circular saw, chipping.

The edges can be with smooth transitions, relatively even. The broken edges of the rubble facing element will increase the working time with the stone. One of the sides will be fairly flat. She lays down on the mortar / glue to the basement of the house.

The adhesive composition can only work with a stone with an area of up to 40 cm², 1 cm thick. More massive fragments for cladding need to be fixed with a mortar with careful sealing of the seams. Estimated quantity required material when buying, correctly increase 1.1 times for bleed, fit according to the pattern.

The main important limiter in the choice of natural raw materials when lining the basement will be incompatibility silicate species(sandstone, quartzite) and carbonate (dolomite, travertine, shell rock, marble, limestone). Silicic acid, released from silicates, reacts with calcium carbonate, a mineral in the base of the calcareous rock. As a result, both the one and the other stone are destroyed many times faster.

The adhesive composition is selected according to the following criteria:

The solution is used for facing works with a plasticizer. Density depending on the type of installation: separately, poured between the slab and the plinth of the house. The bulk method is chosen for finishing monolithic surfaces, separate - on brick, insulated walls. Rows are counted from below. Starting work on the right or on the left does not matter, the main thing is consistently.

Watch a video on how to fix stone plates with your own hands.

Each stone is washed and dried before planting on the solution. Seizing on dust, soil particles will not be of high quality. The same requirements for the surface of the basement of the house.

The stone is immersed in the composition so that the relief protruding part is in a relatively flat plane without drops. The distance between the fragments should be correctly maintained, taking into account thermal expansion. When assembled from different breeds take on the maximum value.

The lower edge of the first row is closed with a blind area. If the soil of the adjoining site is prone to shrinkage, the first row of finishes is supported by a steel corner. The upper part is leveled along a horizontal mark, covered with a visor.

The outer part of the cladding of the house needs to be processed to preserve the external beauty and protect against erosion.

Main methods:

Coating is carried out after the finishing seams have dried.

(Materials for facing the basement of the house)

Before we start talking about finishing, a few words about what a plinth is. In general terms, we can say that this is the part of the foundation located above ground level.

If the house has a strip base, the base is its top part rising above the ground. If the support is columnar, the walls between the pillars (zabirka) or above them (grillage) serve as the base.

The plinth is one of essential elements Houses. Not only the longevity of the building depends on it, but also its appearance. Without competent finishing, the building will not look harmonious and whole. About what outfit you can put on the part of the foundation that rises above the ground, and will be discussed in this article.

The main task of the plinth is to take on the load from the walls and roof and transfer it to the foundation, as well as to protect the base of the house and facades from atmospheric moisture.

Its height is determined individually, depending on architectural features object, but in any case, it must be at least 40 cm. As a rule, the basement is made of concrete or brick (red, since silicate is destroyed by moisture), less often - from natural stone.

But if a granite or wild stone plinth is beautiful in itself, then brick and concrete will most likely require decoration.

Perhaps the easiest way would be to plaster the base and paint. There is only one technical difficulty here.

Since it accumulates at the border with the ground more moisture, it is necessary that the bottom of the plaster layer does not come into contact with the ground. To do this, make a small groove along the walls and fill it with gravel.

FOR INFORMATION: The price of artificial stone varies between 600-1500 rubles / m2. Facing works increase it by an average of 10%.

Plaster coatings rarely "live" for more than 5 years. To avoid the hassle of repairing cracks and touching up, it is better to use more durable materials- stone, clinker tiles or siding.

Plaster is good because it can hide minor wall irregularities, but the main advantage this method finishes in a huge number of colors.

There are as many decor options as there are varieties. facade paint. Beautiful, inexpensive, easy to perform, but, unfortunately, short-lived.

Even the highest quality plaster coating after 2 years will require at least renewal, or even complete replacement. The life of the paint is also not very long. But the decoration of natural stone, subject to all the rules of laying, will last as long as the house itself.

This material will not only reliably protect the plinth, but also give the house solidity and respectability. The advantages of natural stone are obvious, but, alas, its disadvantages are no less obvious.

First of all, the price. As you know, good things don't come cheap. The cost of 1 m2 of such cladding starts from 1500 rubles, and elite stone species are fabulously expensive. The second disadvantage is the large mass, which greatly complicates the installation.

For finishing work, you will have to invite highly qualified specialists, which again entails significant costs. And yet, natural stone has not lost popularity for several centuries.

Note that, like any other individual material, natural stone needs protection.

Upon completion of the cladding, it will be useful to treat the base with special impregnations that will protect the expensive coating from acid rain and prevent the appearance of efflorescence, moss and mold.

For finishing the plinth with clinker tiles, which distinguishes high quality and strength, appropriate adhesive is required. It should be a mixture with high frost resistance and elasticity. You should not save on this.

It would be wise to give preference to specialized compositions designed specifically for such tiles. Before laying, the tile must be dipped into water, otherwise it will "drink" moisture from the solution, depriving it of a binder.

A worthy replacement for natural stone can be an artificial stone.

Moreover, in many respects the copy is superior to the original. So, granite and sandstone have a limited range of colors, while tiles made from Portland cement, sand, lightweight fillers and special additives can be almost anything - from neutral beige or gray to extreme green or blue.

Man-made material authentically imitates wild and sawn stone, brick. Within one collection, several standard sizes of cladding are usually produced.

And special corner elements make the finish almost indistinguishable from the "natural".

Another advantage of artificial stone is the exceptional ease of installation. Any tiler can handle the finishing of the plinth.

In addition, this material is not much inferior in strength to natural stone. Yes, in fact, exceptional strength is not needed here, because the lining does not experience special mechanical loads.

But what is really important is frost resistance. On average, an artificial stone is able to withstand 100-150 freeze-thaw cycles.

And since there can be only two or three such cycles during the winter (or not at all), it is obvious that in terms of resistance to sub-zero temperatures this species cladding has a multiple margin of safety.

Water absorption of artificial stone is usually in the range of 4-9%. To reduce this figure, some manufacturers recommend covering the lined surfaces with special compounds - water repellents.

However, according to most experts, this measure is not mandatory. Protection is needed only when the stone is in constant contact with water.

One of the main advantages basement siding- exceptional ease of installation. Sheathing with vinyl panels can be done on your own, a minimum skill of working with construction tools. The work is also simplified by the fact that every serious manufacturer supplies their products with detailed instructions for installation.

But these instructions must be strictly followed. For example, if you use ordinary nails instead of galvanized ones, rusty streaks soon appear on the surface of the siding. And a nail hammered to the very head will lead to the formation of cracks, since the material will not be able to move with fluctuations in temperature and humidity.

An alternative to plastering can be concreting the basement. To do this, they fix on it metal mesh, and then the formwork is installed and concrete is poured. Upon solidification, it forms a durable surface that can be painted or veneered.

FOR INFORMATION: Prices for cladding made of natural stone of common breeds start from 1500 rubles / m2, and elite varieties are fabulously expensive.

At the moment, artificial stone is perhaps the most popular type of plinth finish. The price of 1 m2 of coverage varies in the range of 600-1500 rubles.

To stone finish served for many decades, several important points. First of all, it is important not to make a mistake with the choice of breed.

It is obvious that for finishing a plinth exposed to rain, snow, hail, etc., a durable, non-porous, frost-resistant stone is needed. Granite and sandstone are best suited.

But soft, loose varieties should not be used. Limestone and shell rock will not withstand the harsh tests of our climate and literally in two or three years they will completely lose their presentation.

Marble is also not intended for outdoor use. If not only the basement, but also the walls of the house are finished with stone, compatibility must also be taken into account. different varieties. Contact of silicate rocks (for example, sandstone) with carbonate rocks (marble, shell rock or limestone) should not be allowed.

When they come into contact, unwanted chemical reactions, and at the joints, both stones begin to rapidly collapse.

Author: Yulia Leshkevich

Magazine: NEW HOUSE

Journal number: №8

Year of issue: 2008

Author: Yulia Leshkevich

Magazine: NEW HOUSE

Journal number: №8

Year of issue: 2008