Despite the fact that in Lately a large number of modern building materials and technologies have appeared during the construction country houses Brick is often used. Well developed production base, high performance characteristics(durability, strength), the ability to create complex architectural forms and decorative details when laying walls, as well as considerations of prestige, ensured this material enormous popularity.

Brick- This is the most expensive and prestigious building material. Houses made from this material have been standing for hundreds of years, and spacious brick house will undoubtedly become your Family Estate, in which you and your great-great-grandchildren will live.

Warm, cozy home made of brick is maximally protected from bad weather and destructive external environment, it will truly become your fortress.

The most widespread are two types of bricks: ceramic (clay) and silicate, made from a lime-sand mixture with various additives.

Clay brick can be solid or hollow in structure. Voids in the material are formed during its molding and can be through or closed. Hollow brick is lighter than solid brick, and masonry made from it has better thermal insulation properties.

The reduction in brick mass due to the presence of voids allows the production of stones bigger size than standard (250x125x65 mm).

The use of one-and-a-half (250x125x88 mm) and double (250x125x138 mm) bricks makes it possible to reduce the consumption of masonry mortar, as well as reduce the time required to build walls.

Sand-lime brick is used less frequently than clay brick, because absorbs moisture well and, as a result, has relatively low frost resistance, which leads to its rapid destruction. In addition, sand-lime brick, unlike ceramic brick, has increased density and lower thermal insulation characteristics.

Advantages brick houses

The bricks that are used to build houses these days are made in the form of fairly lightweight ceramics and usually have many holes in them, which make it possible to give the brick excellent thermal insulation properties.

What else is good about a brick house?

In addition to heat conservation and durability, building brick houses has other benefits. positive sides. The brick meets fire safety standards as it does not burn. No rotting processes occur in the brick, it cannot be damaged by any pests, precipitation and Sun rays it is not affected in any way. The brick allows the required amount of air into the house, and summer period protects the air in the house from overheating.

Brick houses potentially have great architectural possibilities, variety of shapes and expressiveness, allowing you to embody your wildest design fantasies.

You can build any structure - from avant-garde round house to the most complex classical Gothic cathedral.

Disadvantages of brick houses

For finishing brick houses there are many various options. But it must be said that the need to use any materials for finishing brick houses is considered negative side brick construction. However, compared to all the advantages of brick houses, this nuance is not significant. However, we should not forget that due to cement mortar, which is used to cover the walls during finishing, a brick house loses about a third of its heat, because cement is one of the building materials that have high thermal conductivity. But thanks to special insulation materials, it is still possible to avoid this level of heat loss at home.

Brick feature, which is very undesirable, but nevertheless present, is its hygroscopicity. Considering that brick, like a sponge, quickly absorbs moisture, the house needs to be heated very well so that the walls are not too wet and do not accumulate cold and dampness.

Brick houses are not suitable for temporary living. If a brick house has been unheated for some time, then upon returning to it you feel like you are in a basement - cold and damp. It will take more than one day to warm up a brick house well, i.e. It will become warm just when it’s time to leave. To avoid this, you need to either live in such a house permanently, or maintain the heat automatically.

As mentioned earlier, a brick does not ignite, but despite this, fire can cause great damage to it. After a fire, a brick loses more than sixty percent of its strength, that is, it becomes very loose.

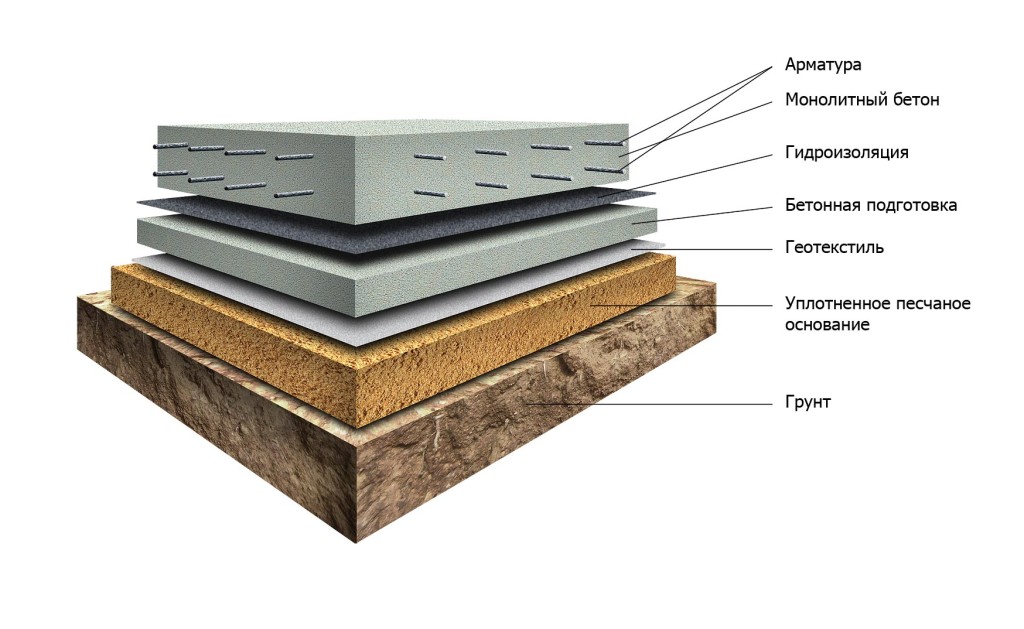

The disadvantage of building brick houses is that, due to the large mass of the walls, for such houses it is necessary to prepare a very powerful foundation to the depth of soil freezing.

The disadvantages of brick construction are mainly associated with the labor-intensive construction of walls, which means, despite the comparative cheapness source material, building with brick is ultimately not cheap. In addition, brick construction involves the use of so-called wet technologies, and this entails restrictions on weather conditions. During severe frosts or heavy rains, construction has to be suspended, which further increases the time and, therefore, increases the cost of construction.

Possibilities design solutions for brick houses are very wide. Exist different kinds facing bricks, thanks to which it is possible to bring almost any idea to life.

Types of bricks

As practice shows, an ordinary buyer, when faced with the choice of bricks for construction for the first time country house, I am surprised by the number of varieties of this material presented on the market today.

So, the most inexpensive and common type of this material is ordinary solid brick .

Usually it is a red block, without holes or any frills. Frost-resistant. Has porosity from 8% to 20%. According to its purpose, it is intended to become the basis of the masonry. Columns and vaults are also built from it.

Ordinary brick masonry, as a rule, requires further covering with plaster or other facing material.

To increase the thermal insulation properties of brick, it is constantly being modernized.

The first step towards preserving heat was the release hollow brick

.

The first step towards preserving heat was the release hollow brick

.

This material has through and non-through voids. They are round, slot-shaped, oval or square. The diameter of the through voids does not exceed 16 mm, and the width of the gap is 12 mm, therefore, during the laying process, the mortar slightly fills these voids, which reduce thermal conductivity. A brick is considered hollow if its void volume is above 13%. In addition to heat conservation, when producing such bricks, it is possible to save on raw materials for its production, on the thickness of external walls and on transportation costs. In addition, it has higher frost resistance, it is easier to fire and, thanks to its use, it is possible to reduce the load on the foundation.

Another type of ordinary brick hollow porous

. During its production, sawdust is added to the raw material, which, when burned out during firing, creates micropores.

Another type of ordinary brick hollow porous

. During its production, sawdust is added to the raw material, which, when burned out during firing, creates micropores.

The brick becomes “warmer” due to the internal porosity of the material. Compared to ordinary brick, porous brick has a significantly lower density, due to which it has better heat and sound insulation properties.

For external work, facing or facade brick. Its color, depending on the raw material, ranges from light yellow to dark red. It perfectly withstands the effects of water and frost, taking all the weather's blows upon itself.

This species is definitely in the higher price range.

Also known in construction are glazed and engobed bricks, facing clinker bricks, figured bricks, ceramic block and etc.

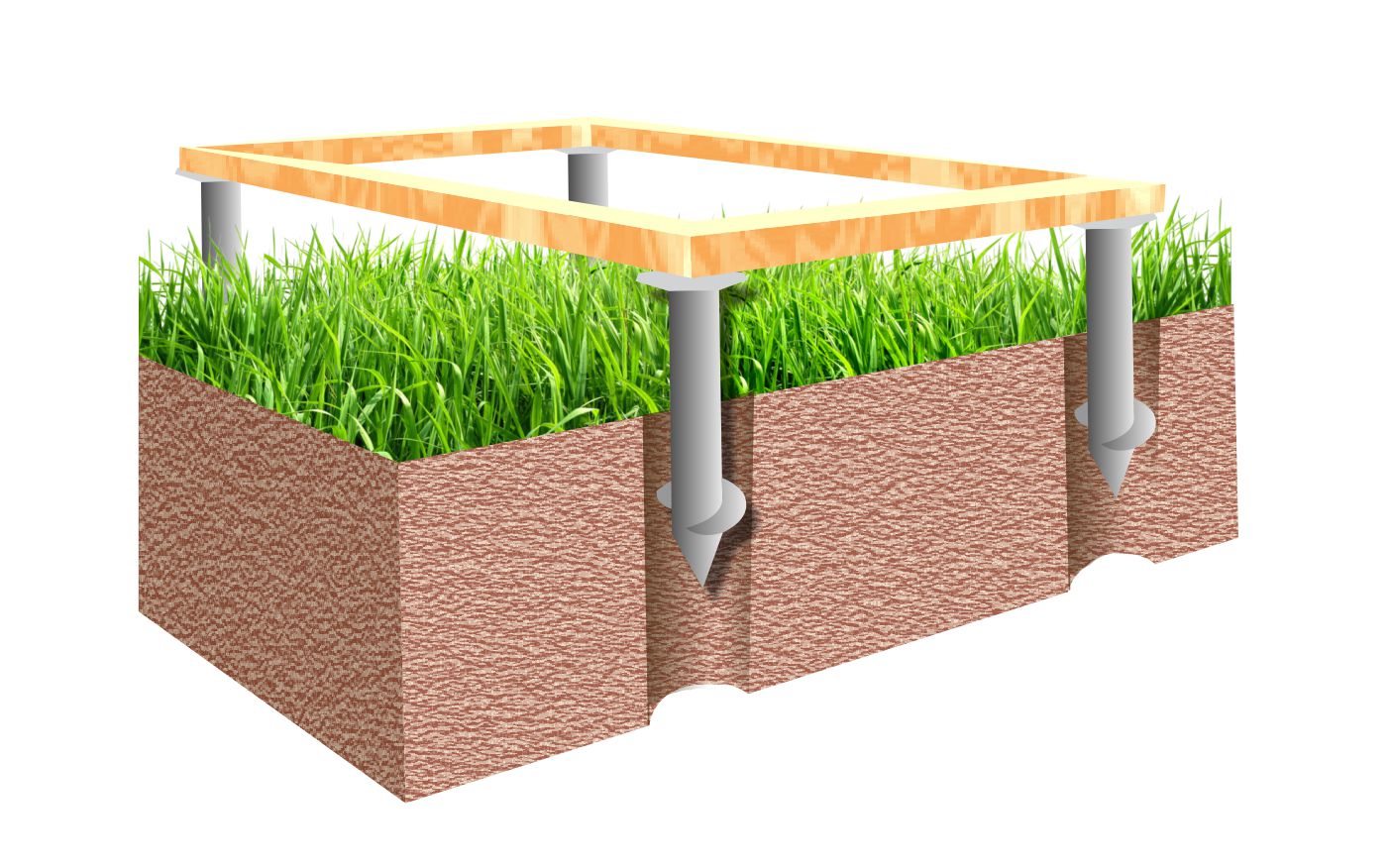

You can build the foundation for a house yourself, because the process itself does not require excessive effort. All you need is to approach the issue knowledgeably, be fluent in the nuances in this matter, understand the differences between the types of foundations, take into account the strengths and weak sides all options and masterfully master necessary set construction tools. Adhering to the main rules of laying the foundation for brick house, the finished construction will be successful.

This foundation differs little from its predecessor. The pillars are simply tied with a special tape. But the apparent simplicity should not be misleading, there are features and subtleties. If you know them, you can get a strong and durable building for many years.

IN individual construction this type of foundation is found everywhere, but it can also be used for the construction industrial buildings. This type of foundation is especially good when constructing basements and in places with a large depth of soil freezing.

It is clear that no construction can be done without creating a reliable foundation for the building under construction. It is its reliability that will ensure the quality and practicality of any home.

Sometimes a brand new house purchased suddenly develops a crack in the wall. This could be a sign of a poor-quality or simply weak foundation that is not doing its job and cannot support the weight of the house.

This situation requires an immediate solution in the form of strengthening the foundation. The easiest and most affordable way is to increase the area of the foundation under a brick house. However, there are many more types of foundation strengthening. Each method is good in its own way and can be used depending on the circumstances, the number of floors and architecture of the house, as well as the type of foundation. The main thing is that a way out can be found in any, even the most difficult situation, when the foundation cannot stand it and requires decisive action to strengthen it.

You can talk almost endlessly about brick, listing its advantages and qualities of a built house. Many people have an ingrained opinion that anyone can work with this building material - just mix the mortar and start construction.

Maybe for small ones garden buildings this is true, but in relation to large cottages you should know many of the features of brick and follow the construction technology in accordance with the requirements of SNiP and design documentation.

You should trust exclusively professionals trained to perform this work. This can be compared to going to the doctor - after all, you won’t go to the dentist for cold medicine. The principle is almost exactly the same - you cannot entrust the construction of a future family nest to builders with very low qualifications and questionable skills. This can only be achieved by increasing the costs of correcting mistakes. The InnovaStroy team has been working in the market for the construction of private brick houses for many years and will offer its professional services to everyone who wants it.

The construction of load-bearing structures and partitions requires a certain level of skill and proficiency in tools. It is also important to understand the principle of laying bricks in walls for various purposes and directions of use. The main division of building elements is made by width, depending on the purpose. A brick placed perpendicular to the plane of the wall with a length of 250 millimeters is taken as the reference size. Focusing on design features buildings, walls can be made in width - from ¼ brick to 2.5. Wider ones are not used in private construction, as they require a very large consumption of material and take up the usable area of the house. Promotion thermal insulation characteristics produced by insulation and external cladding.

To understand technology brickwork walls, you need to understand several terms often used in construction:

By type construction tools We will not provide descriptions, since everyone knows perfectly well what a trowel is and how to work with it. It is worth noting that it is important to maintain the vertical and horizontal evenness of the wall so that there are no bulges or deviations from the ideal surface. In principle, brick masonry wall technologies allow a slight distortion in the uniformity of rows up to 1%, but it is never perceived by our specialists, since these errors are simply unacceptable from an aesthetic and professional point of view. This is especially true for front surfaces without further exterior finishing.

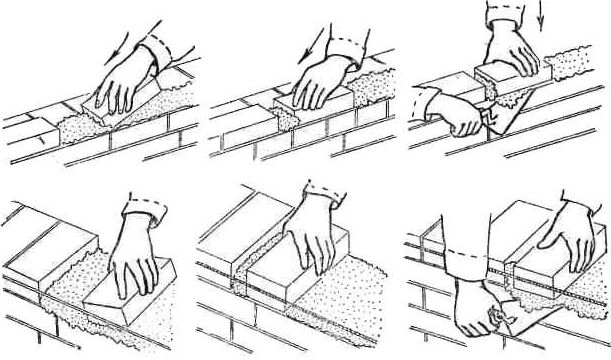

In everyday life, several options for laying the material using fired clay material are used. They are suitable for both cement and clay fastening mortars - the main thing is to follow the technology and ensure the strength of the structure. Each method described below will talk specifically about the brickwork and techniques used by our builders.

The method, suitable for creating almost any wall, allows you to control every moment of installation. It is quite labor-intensive, but in terms of effectiveness it surpasses all other installation options. The pressing method is recommended for use with solutions whose plasticity does not exceed 7-9 centimeters of cone draft, that is, with compositions that are quite dense in structure. The method is used for laying any type (spoon or butt) to obtain a uniform and even wall shape.

The principle of operation is quite simple, but labor-intensive, which affects the speed of construction of structures and the time spent on a certain amount of work:

As a rule, with this type of masonry there is no need to remove the protruding bonding mixture, since its volume is precisely regulated. Using a trowel, remove the squeezed out mortar from the back side of the verst and along the transverse seam at the top.

This technology for constructing brick walls is used with mortars that have a plasticity of 12-13 centimeters of cone shrinkage, that is, with fairly liquid mixtures. The method is suitable for constructing most types of walls, but is most often used when forming empty masonry. This implies a distance from the front edge of the brick to the fastening mortar of about 1.5-2 centimeters. The resulting space is used to fill finishing materials, like textured plaster. You can see examples and options for external finishing of brick walls in our company’s catalog, which represents.

The installation principle is very similar to that described above, but has certain differences. For example, a bed is laid on the bottom layer of masonry at a distance of 2-3 centimeters from the front edge. A little more mortar is needed, since the next brick in the row will scoop up part of the mixture onto its face and then dock to the previous one. Leveling and flooding also occurs along the level line or cord indicating the masonry line. Do not forget about the transverse level that must be maintained. It is controlled using a special short tool or a perfectly straight bar.

A very common technology for constructing brick walls, which is used very often. Its peculiarity is that the solution is applied to all surfaces of the previous row and adjacent bricks. During the process of laying and pressing, all excess mixture that appears along the seams is removed with a trowel. Then the seams are unstitched, which may have different shapes– from convex to triangular. It depends on the aesthetic preferences of the customer.

For this type of brick laying to be successful, you need to use a solution with a certain cone shrinkage rate - from 10 to 12 centimeters. This optimal parameter, in which the solution does not spread and hardens slowly enough to have time to embroider 5-6 new rows in the vertical and horizontal directions.

All of the above should be known to true professionals in the field of building brick houses. But few people are aware of some of the features that working with brickwork has. Here are some points that should not be ignored:

When did you finally decide to give preference to the classic building material and have selected an approximate view of the future family nest, contact our professionals. Architects and designers will make bricks in compliance with all technologies of their construction. A construction crews will complete assigned tasks in full accordance with state standards and norms technical documentation. Constant supervision of construction guarantees high quality execution, especially since our architects know exactly how to work with a trowel in practice, and not from videos from the Internet.

22.09.2011 Technology of building a brick house.

A brick house always inspires admiration. After all, it provides a high degree of security, is durable and strong. But besides this, unlike wooden structures it is not susceptible to biological factors, atmospheric influences. Although brick belongs to artificial stones, but its strength is comparable to stone. Brick can be solid or hollow. If the area has high humidity, then it is not recommended to use sand-lime brick, since it is more hygroscopic. When constructing external walls, hollow bricks are used. To cover the facade, it is necessary to use bricks of the same color and brand, and the design of the facade must be approved in advance.

The technology involves laying on binder mortars, which consist of sand, cement and water. If necessary, then some chemical components are added to them, especially if the work is carried out in winter time. Masonry mortar can be prepared in a concrete mixer or by hand. Its quantity should be such that it is consumed before the onset of viscosity. The strength of the masonry will be high if you use it every 5 rows reinforced mesh. In the construction of cottages, three-layer masonry has become popular, which, even with thin walls, requires high thermal performance. Effective brick is used for the load-bearing part, and facing brick is used for the self-supporting part.

If a brick house is being built in winter, then the mortar must be resistant to low temperatures. After all, for hardening the solution requires a humid environment, as well as a positive temperature. If the temperature decreases, then the efficiency of the process decreases, and if it is negative, it stops. When the solution freezes, it loses its plasticity and its horizontal seams do not seal. The thawing process results in uneven precipitation. The entire structure will lose strength and stability. The solution itself hardens in 28 days. If average temperatures decrease, the strength will decrease by 50%. To prevent this, it is necessary to use those components that increase the solution’s resistance to low temperatures. But even such a frost-resistant solution requires high-quality filled masonry joints. The brick is laid and jointing done quite quickly. It takes two hours for the masonry to freeze. The process of compressing the solution occurs only when it has completely thawed (at spring time or during a thaw). Therefore, if the thickness of the seam is allowed to exceed the standard, the consequences can be extremely unpleasant, from severe settlement to the destruction of the wall.

Unfinished brickwork is covered with a thick layer of roofing felt. And before starting work, the surface must be thoroughly cleaned of frozen mortar, snow, and ice. The technology for building a brick house uses polystyrene foam boards or basalt fiber boards for thermal insulation. When insulating a wall of 51 cm, you can achieve heat-insulating qualities comparable to brickwork 2 times thicker. Between thermal insulation boards and outer wall it is necessary to make a ventilated layer, 20-30 cm thick. Ideal ventilation is achieved with upper vents at the eaves, and lower vents at the plinths. Since creating this gap is a complex and expensive procedure, some builders use a compromise solution. They put insulation without using air gap, directly into the body of the brickwork. In the case of three-layer masonry, porous-hollow or hollow bricks are used.

The construction of turnkey brick houses is naturally divided into several stages and can be carried out and paid for in stages.

After all the main external work on the construction of a country house has been completed, you can begin to arrange the site.

The logic of the further progress of construction of a brick country house is as follows: in order to begin interior decoration - painting walls, laying parquet, etc. - a certain temperature and humidity regime is needed, which means the thermal circuit must be closed (windows and doors installed) and the heating is on.

The heating circuit closes after the house has dried out sufficiently. Until this time it is necessary to ensure good ventilation, the easiest way is natural.

Installed internal partitions in accordance with the plan.

Then electrical wiring, heating system pipes and other installations are carried out. engineering communications, walls are plastered, this is done if this is provided for in the project, concrete screed with a “warm floor” system, heating radiators are hung, although at the stage finishing They will have to be removed for a while - and you can turn on the heating.

When will it be installed in the house? desired temperature and the temperature and humidity conditions stabilize, they begin the last stage of building a brick house - finishing.

Interior decoration of the walls of brick houses, as a rule, consists of painting, finishing decorative plaster or wallpapering. There are many very beautiful and original finishing systems. Actually, interior decoration brick houses have no limitations and depend entirely on your imagination.

Construction company " Vacation home» carries out all stages of turnkey construction of brick houses using ready-made or modified standard projects, as well as their individual design and construction.