Oak barrel- a great thing for a person. You can pickle vegetables in it, make wine, moonshine, and cognac. At worst, just sit until it dawns on you, as some do, a great idea. It is not for nothing that in the old days the production of barrels was the domain of real craftsmen. We continue to tell you about things that you can master in your dacha. Next up is cooperage.

Unlike many endangered professions, such as saddler, lamplighter or carriage maker, coopers are still in demand in the 21st century. The production of tubs, barrels and decorative bar elements is now on stream. Beer and wine containers are manufactured industrially - spacious workshops, computer quality control, wholesale supplies. The cost, depending on the volume, ranges from several hundred to tens of thousands of rubles.

But, of course, the Russian person’s craving for things made with my own hands, nothing can win. Therefore, if you decide to make the barrel of your dreams yourself, we can only advise you! Follow the recommendations below - and any Diogenes will thank you!

So where does the barrel start?

Tree selection

Of course, you'll need oak first. Moreover, not the first one that comes across, but more or less mature, with a trunk diameter of 40-60 cm. Some specimens can be rejected even at the inspection stage. Thus, the characteristic bumps on the trunk indicate that the giant is infected with tobacco rot.

We also “weed out” twisted and knotty trees. In cooperage, only “sprat” is used - the first 4 meters of the trunk, the rest can be safely turned into fuel for the barbecue. Yes, if you can’t cut down the tree you like, you can always buy a similar one at the nearest sawmill.

Manufacturing of rivets

Now a little theory. The barrel consists of wooden parts, rivets, tightly fitted to each other and tightened with metal hoops. And the final quality of the entire product directly depends on how accurately the manufacturing technology of these elements was followed.

First of all, decide on the dimensions of the future barrel. Its height will affect the length of the riveting itself (it should be 2.5–3 cm longer).

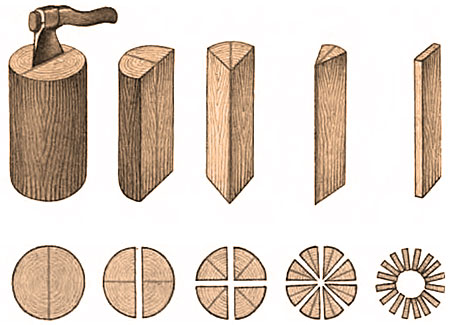

Have you chosen your size? Cut the previously prepared oak round timber into it. It’s good to have a hydraulic splitter on your farm. Well, if not, the oak log is split into sectors using the old-fashioned method, using wedges. The result should be 8 radially split ingots.

Now we cut off the core and soft “white” fabric into circular saw. From the resulting blanks we plan out even boards of equal thickness using a surface planer.

Ready? Now... stack all this beauty in stacks somewhere under a canopy. And leave it for at least a few months. Or better yet, for a year - they don’t make a good oak barrel in an hour☺. During this time, the sun and wind, without creating unnecessary stress on the wood, will remove excess moisture from it. For now, you can take up grapes (by the way, there are excellent varieties for the Moscow region, we’ll definitely tell you about them someday). When the workpieces dry, you can continue. Using a jigsaw, give the boards the correct cigar-shaped shape, where the thickening will be only 0.8–1 cm wider than the ends.

The inner edge of the workpieces is trimmed in the middle with a curved plow. Less than a millimeter is enough, and when necessary, the rivets will bend in the right place. We give the outer edge the shape of an arc, the curvature of which is determined by a special pattern. Its radius depends on the radius of the barrel being manufactured. The tool is easy to make yourself. The result should be a product the same as in the picture.

On average, you will need from 25 to 30 staves per barrel.

Making a hoop

When the rivets are prepared, you can start making hoops. You will need a narrow strip of 2-3 mm iron, slightly longer than the circumference of the frame.

Twist it into a ring and secure it at the ends with rivets. The hoop is almost ready. Flare lightly with a hammer inner side– and can be put on the frame. For a small barrel you will need two pairs of hoops. Not less! What if some ring can't withstand the fermentation of your beer?

While you are working with iron, make a couple more metal staples. They will later serve as “clothespins”.

Assembling the barrel

The rivets are prepared, the hoops are ready. It's time to collect it all in a pot-bellied barrel. Take the finished ring and secure the ends of two or three rivets in it with clothespins in random places. The design will resemble a stool. In this position, fill the entire perimeter of the hoop with rivets. When the last board is in place, hammer the metal belt to fit the parts more tightly.

But before putting on the second hoop, the wood will have to be heated and steamed. It's done like this. We bring our semi-finished product to Fresh air and install it with the “socket” facing up. A small metal urn filled with wood chips is placed inside. We light a “fire” in it. While the fire is burning, wet the wood generously with water. This will keep it from catching fire and add flexibility to the boards. After half an hour of this “bath”, throw a noose on the end free from the hoop and pull it quietly with a winch. There is no rush in this place. The path to the finish line can take from 40 minutes to 3-4 hours, but any broken rivet will immediately return you to the beginning of the distance.

As soon as the wooden fan closes, immediately stuff the hoop. Just don’t forget the old Bondar law: “You can’t knock on the same place twice with a hammer.” In simple words When lowering the hoop, apply only one blow to each place. Under no circumstances hit there two or three times - you will split the wood.

When the metal belts are in place, the frame of the barrel ends up. The internal cavity is leveled with a special scraper and sanded with sandpaper.

And now another trial by fire. So that the tree gets used to its new form, it needs to be burned. The scheme is the same - the wood chips burn in the urn. Stir the fire constantly, otherwise the barrel will catch fire. There are no ready-made recipes here. If you set fire to the boards, the wine will take on a burning smell. If you finish firing ahead of time, the rivets will tear the hoop.

Manufacturing and installation of bottoms

At a distance of up to 2.5 cm from the ends of the frame, select the so-called morning groove. The bottom will then be inserted into it. Previously, such an operation was trusted only to a special incisor, a morning dresser (another endangered profession!). Today it is much easier to use a cutter. At the same time, remove the chamfers from the ends of the barrel. Useful when shrinking the bottoms.

To make them you will need rivets again, just a little large sizes. They are connected into panels with steel nails without heads. By actually measuring the length of the mouth groove, you can easily determine the radius of the bottom. Outline it on the shield and cut it out with a jigsaw. Sharpen the ends of the round.

The connection between the bottom and the frame looks like this.

To put the bottom in its place, the frame will have to be unchained on one side. The rivets should already be in shape by this time. Insert the round piece into the morning groove, press it into place with a mallet, and tighten the product again with the hoop. If everything is done correctly, the bottom will not leak. Before repeating the operation with the other bottom, cut a drain hole in it. Diameter – 32 mm. When everything is ready, we polish the barrel, giving it a marketable appearance, and prepare it for soaking.

Soak

In principle, the barrel is already ready. One could calm down on this, but the wood is still too saturated with tannins and tannins. Therefore, you will have to soak them, otherwise the contents of the barrel will deteriorate.

Fill the container one third with hot (80 °C) water. Rotate the barrel for half an hour so that the moisture moves around the entire perimeter. Next, drain the liquid and replace it with cold one. It should stand in the container for a day, after which it must be replaced again. And so on for two weeks. Some people soak the barrel with ready-made wine, others with moonshine. Everyone has their own style. But it’s worth starting with water.

Now the barrel is really ready for wine. Or beer. Or moonshine with cucumbers - what do you choose?..

The best brands of cognac, wine, liqueur, rum, and whiskey are aged in wooden containers. IN household barrels, tubs are also rightfully considered best place storage for pickles. In terms of sanitary and hygienic characteristics, they are not much inferior to containers made of of stainless steel, but surpass the latter in a number of quality indicators. Natural material creates a favorable environment for ripening products, giving them original aromatic and taste properties. You can make an oak barrel with your own hands if you carefully read the step by step guide for the manufacture of this desired product.

Professionals high level units, but this does not mean that the work cannot be completed. The requirements for making the required container at home are different. It is enough to make a structure that can withstand moderate loads during operation. The Bondar must have skills and knowledge in the following areas of activity:

In the classic production of wooden containers, no adhesives or metal fasteners are used, with the exception of outer hoops. All connections are made by precise fitting of parts. Slots and gaps that make the product unsuitable for solving the assigned tasks are not allowed. A well-made barrel or tub, after assembly without soaking, should have the required tightness. In some cases, small leaks are allowed if the wood dries out, which can be easily eliminated by moistening and swelling the natural fiber.

The technology for producing wooden containers requires precise, step-by-step execution operations, from the selection of raw materials to decorative finishing outside products. To make an oak barrel with your own hands, you need to know what it consists of:

It is important to comply precise recommendations professionals at every stage of work. It is impossible to make a cooperage product of satisfactory quality without violating even one point of technology. The step-by-step production process is as follows:

The geometric dimensions of the riveting in each case are original, depending on the height of the barrel, the degree of bending of the workpiece, its width, and the bevel angle of the end part for a tight fit with the adjacent element. You should accurately repeat the dimensions indicated in the existing drawings, or, having knowledge of the spatial construction of complex figures, independently determine the required values.

Cooperage products can be made from various types of wood. However, oak barrels are considered the best. The choice is not accidental, since in addition to strength and durability, the material has unique biochemical characteristics to create optimal conditions storage of drinks, food products. Natural substances in oak wood fiber have an antiseptic effect and give pickles and alcoholic drinks unique taste and aromatic characteristics.

Experienced coopers choose raw materials when the tree is still growing. It is specially cut down and subsequently cut into the necessary pieces. The lower part of the trunk is used, on which there should be no branches, visible bumps or bends. Usually it is 4-5 meters from the root, when the plant is at least 100 years old. It is difficult to fulfill these conditions at home if the master is not a native inhabitant of the forest. Therefore, the criterion for choosing wood for staves becomes the visible quality of the fiber. The requirements are:

How to do wooden barrel do it yourself, drawings and detailed description on production.

The figure shows a section of a barrel:

1.

Lid.

2.

Small hoop.

3.

Boards (rivets).

4.

Big hoop.

5.

Bottom.

The manufacturing process of the product in question can be divided into several stages.

MATERIAL SELECTION

The most common material is oak. Oak barrels are good for aging alcohol and storing pickles for the winter. You can also use cherry, mulberry, linden, aspen or ash.

CALCULATION OF THE DESIGN

Any design is determined by the following dimensions:

Height (H) – 600 (mm)

small diameter (d) – 420 (mm)

large diameter(D) – 465 (mm)

number of rivets (n) – 20

angle of inclination of the side faces to the center of the regular polyhedron (φ) – 360/20/2 = 9°

Using geometric constructions we obtain the dimensions of the riveting.

Reference:

To significantly facilitate assembly, it is advisable to make the rivets at the top and bottom thicker than in the center by 1/5. If the thickness of the riveting in the center is 10 (mm), then at the edges it will be 10 + 10/5 = 12 (mm).

PREPARATION OF MATERIAL

The lower part of the trunk, sawn into logs, is well suited for blanks. Chocks of the required length must be split into boards in the direction of the grain. Send the prepared boards to dry in a ventilated area for a period of two months.

Reference:

To ensure that the boards are well-ventilated, it is better to fold them in a checkerboard pattern.

MANUFACTURING HOOPS

Hoops can be made from hot-rolled tool strip 3 x 30 (mm). Perfect option, if you bend the strip to , but you can also do it manually. Drill two holes and connect the ends of the hoop with rivets, as shown in the figure.

BOTTOM ASSEMBLY

We will assemble the bottom from boards and slats. We mill grooves in the boards along the entire length of the end surface. We will insert the planks into the grooves and press the boards together.

From the resulting shield, cut out the bottom of the estimated diameter.

We grind the end surface at a slight angle.

How to make a wooden barrel with your own hands, the drawings are at hand, all the parts are made, you can start assembling the product:

1.

We assemble rivets around the perimeter of the small hoop, using small homemade clamps.

2.

After inserting the last rivet, push the hoop as far as possible towards the center of the barrel length.

3.

Reheat in hot water for 15...20 (min) lower rivets.

4.

Place the prepared structure inside a large hoop, preferably on a flat surface.

5.

We tighten the structure with twine and move the large ring to the center of the barrel.

6.

We continue to tighten the structure with twine, after the rivets are completely pulled together, we put a small hoop on top of them.

7.

The frame is assembled and must be burned from the inside using any of the proposed methods: gas-burner; blowtorch; small fire.

8.

Align the edges of the barrel.

9.

Loosen the lower metal ring, insert the bottom into the grooves of the rivets, and push the small metal hoop back to its original position.

10.

Do the same this operation with lid.

11.

Check the product for leaks and, if necessary, seal the cracks with barrel grass.

12.

Sand it down outer surface product and cover it with a thin layer of beeswax.

13.

If the barrel is made of oak, it must be washed with water until the drained liquid becomes clear. This procedure can take up to two weeks.

As you can see, making a wooden barrel with your own hands is quite possible.

You can buy almost everything today. But it’s quite difficult to find a wooden barrel that’s really high-quality and solid, and it’s also expensive. There is one more point that not everyone takes into account - it is not a fact that the finished barrel will be suitable for a specific purpose. The reason is the mismatch of wood species. The conclusion is clear - make the barrel yourself. And if you understand the drawings and nuances of the work in detail, then it will not turn out to be in any way complicated or impossible to do with your own hands.

Strength combined with ease of processing.

Heavy weight.

Recommendation – it is advisable to use it for the manufacture of relatively small barrels for transportation (storage) of bulk materials.

High cost of material. To make a high-quality barrel, you will have to use wood that is at least 80–100 years old.

Recommendation - if the barrel is intended for storing (fermenting) products, aging wines, and so on, then you should choose oak boards.According to reviews from those who have already made a wooden barrel with their own hands, you can also use such types of wood as linden, ash, aspen, and mulberry.

The choice of material is a rather specific issue. If a barrel is needed to store stocks of wine (cognac, vodka), sourdough (pickling) of cucumbers, watermelons, apples, and so on, then best tree for her - oak. This is undeniable. But to spend such wood (taking into account its cost) to make a container with your own hands in which you are supposed to store cement, sand, bulk products, is hardly correct. Other “simpler” breeds are also quite suitable for these purposes.

Based on its purpose and installation location, the dimensions and design features. There is some confusion with the concepts in everyday life. In principle, both a tub and a barrel are containers of a certain capacity that are assembled by hand from separate boards (rivets, frets in the language of professionals). The only difference is in geometry. The pictures explain everything well.

What is defined for a drawing:

To simplify calculations, it is advisable to focus on standard data that is used by specialists when drawing up drawings of barrels.

The algorithm of actions is clear from the figures, which indicate the main stages of the work.

But some explanations will not be superfluous.

Staves can be made from logs or boards. The first option is preferable, although doing it yourself is much more difficult. The fact is that only the lower part of the tree trunk, from roots to branches, is used to make a barrel. You will have to chop the logs (blocks) yourself.

What's special?

To facilitate bending, the rivets are given an irregular geometry. The thickness at the ends of each board should exceed the same parameter in the center by approximately 0.2. That is, if you plan to assemble a barrel with your own hands from 10 mm boards, then they are trimmed so that in the lower and upper parts of the container their thickness is at least 12.

Various sources indicate periods that are measured in months, or even years (up to 3). On this point, it is necessary to focus on local conditions, initial porosity and its porosity. Recommendations for artificially accelerating this process when doing work yourself are not entirely useful. Without practice, it is difficult to determine optimal mode for the same electrical cabinet and the time the wood is kept in it. Experienced craftsmen It is advised to wait until the moisture evaporates from the wood naturally.

You just need to place it in a room with proper conditions - a temperature of at least +20 ºС and good ventilation. You may have to wait 2 or 3 years. But a high-quality barrel is not made “in one day,” and this must be understood.

If we're talking about about containers for household purposes, then you can dry the rivets even on the stove. But in any case, a barrel is not assembled from raw boards. Within a couple of weeks (due to wood shrinkage), cracks will begin to appear between them. Verified.

Finding metal strips and drilling holes for rivets with your own hands is easy. The only thing you should pay attention to is that it is better to take tool steel. It is characterized by increased tensile strength and corrosion resistance. If you pre-treat it with drying oil and then burn it (for example, with a blowtorch), you will get hoops of an original light brown hue.

It is cut from a shield, which is assembled with your own hands from pre-prepared boards. Moreover, using a different technology than frets (sidewalls). Their thickness does not change along the length. To ensure the tightness of the joints, the ends are milled, that is, the assembly is carried out according to the well-known “tongue and groove” principle. In some cases, special (sealing) strips are installed.

The sequence of actions is shown in this figure.

Such work cannot be done alone; 2 - 3 assistants will definitely be needed. The rivets are placed along the lower hoop with maximum fit. If the last board does not “fit”, it should be lightly trimmed to size. This is where spare parts come in handy, since the first or even the second time, with your own hands, without experience, you may not be able to fit the “finishing” board. A small overkill with the wood sample, and it will have to be rejected.

And only after this the hoops are tightened (if they are adjustable) or finally seated in place (in height).

How to treat the outside of the barrel is decided on the spot (“sandpaper” and by hand, sandpaper/machine), but after this it is advisable to cover the container with beeswax (a thin layer). This will ensure additional protection wood from external factors.

Good luck to you, aspiring coopers!

Preparation of moonshine and alcohol for personal use

absolutely legal!

After the collapse of the USSR, the new government stopped the fight against moonshine. Criminal liability and fines were abolished, and the article banning the production of alcohol-containing products at home was removed from the Criminal Code of the Russian Federation. To this day, there is not a single law that prohibits you and me from engaging in our favorite hobby - preparing alcohol at home. This is evidenced by the Federal Law of July 8, 1999 No. 143-FZ “On Administrative Responsibility legal entities(organizations) and individual entrepreneurs for offenses in the field of production and turnover ethyl alcohol, alcoholic and alcohol-containing products" (Collection of legislation Russian Federation, 1999, N 28, art. 3476).

Excerpt from Federal Law RF:

“The effect of this Federal Law does not apply to the activities of citizens (individuals) producing products containing ethyl alcohol for purposes other than sale.”

Moonshining in other countries:

In Kazakhstan in accordance with the Code of the Republic of Kazakhstan on Administrative Offenses dated January 30, 2001 N 155, the following liability is provided. Thus, according to Article 335 “Manufacture and sale of home-made alcoholic beverages”, illegal production of moonshine, chacha, mulberry vodka, mash and other alcoholic beverages for the purpose of sale, as well as the sale of these alcoholic beverages, entails a fine in the amount of thirty monthly calculation indices with confiscation of alcoholic beverages , apparatus, raw materials and equipment for their manufacture, as well as money and other valuables received from their sale. However, the law does not prohibit the preparation of alcohol for personal use.

In Ukraine and Belarus things are different. Articles No. 176 and No. 177 of the Code of Ukraine on Administrative Offenses provide for the imposition of fines in the amount of three to ten tax-free minimum wages for the production and storage of moonshine without the purpose of sale, for the storage of devices* for its production without the purpose of sale.

Article 12.43 repeats this information almost word for word. “Production or acquisition of strong alcoholic beverages (moonshine), semi-finished products for their production (mash), storage of apparatus for their production” in the Code of the Republic of Belarus on Administrative Offenses. Point No. 1 states: “Manufacturing individuals strong alcoholic drinks (moonshine), semi-finished products for their production (mash), as well as storage of devices* used for their production - entail a warning or a fine of up to five basic units with confiscation of these drinks, semi-finished products and devices.”

*Purchase moonshine stills For home use It’s still possible, since their second purpose is to distill water and obtain components for natural cosmetics and perfumes.