Moreover, it is used both for external and interior decoration premises.

The fact is that the use of this building material ensures not only a long service life, but also a presentable appearance of the building. Brick-like facade facing tiles make it aesthetically beautiful due to the wide selection of colors and textures of the material.

This type of façade is very durable and cost-effective. At first glance it looks like brickwork. But facade slabs differ from bricks in their lighter weight and rather low price.

Thanks to the ergonomic packaging, the material is convenient to transport. And taking into account the technical parameters and attractiveness of the design, brick-like facade clinker tiles are rightfully called one of the most successful inventions in the field of building cladding.

Particularly appropriate this material in cases where it is not possible or impractical to use building bricks due to their high cost. This situation arises, for example, during restoration work on ancient buildings.

Thus, interesting design will provide the building with a presentable appearance, as well as make it warmer and more comfortable. After all, brick-like facade slabs do not deteriorate under the influence of low temperatures and help maintain the optimal temperature level inside the room itself.

Brick-like facing tiles for facades do not require any special installation on the wall of the building. The only exception is the fact that this material is laid in a run-up, like a double sand-lime brick M 150, and not seam to seam, as ordinary tiles are laid.

You can learn how to install this material yourself, as well as prepare a wall for it quite quickly.

Facing tiles for brick facades requires impeccable laying. This can be achieved by using lighthouse plaster.

Of course, you can level the wall during installation yourself, but this will require a lot of tinkering. Also, such a technology can allow voids that are extremely undesirable for further facade cladding building.

At the very beginning of installation, as the instructions for laying this building material say, it is necessary:

Note!

A layer should not fall off the wall old plaster or paint, and there should be no decorative items on the wall surface.

Otherwise, adhesion may occur.

Advice!

The outer beacons must be installed according to the level, and only then the intermediate ones are added.

This ensures the evenness of the wall surface.

Advice!

Installation of beacons can be difficult due to the fact that they will not adhere well to cement mortar.

To solve the problem, tile adhesive is added to it in a ratio of one to one.

It is better to carry out plastering work in dry, cool weather, otherwise the layer will crack. If the work is carried out on a hot day, it is necessary to water the wall with water several times a day.

Brick-like facing tiles for facades should be installed on a dry surface using the following method:

We talked about how facade facing tiles are laid under brick so that they reliably strengthen the walls and provide the building with a unique design. In the video presented in this article you will find Additional information on this topic.

A house is not only a fortress where its owners can feel safe. An important necessity from an aesthetic point of view is that wall surfaces serve as decoration for the building and attract admiring glances from others. It is also imperative that the walls reliably protect from bad weather and guarantee energy savings.

To meet such requirements, building materials manufacturers produce different kinds facing materials. At the same time, according to reviews from home owners, brick-like tiles are the most popular. It imitates natural building material so accurately that you may not notice the difference between brick walls and tiled wall surfaces.

Two types are produced from clay ceramic tiles, differing from each other in the method of production. The first option is porcelain stoneware. The material has increased strength due to production technology. The raw mass is pressed under high pressure and is fired at a temperature of 1300 0 C. This is a non-porous material, comparable in structure to a monolith. Porcelain tiles practically do not wear out under the influence of wind, frost, moisture and temperature changes.

The standard dimensions of porcelain stoneware tiles are 36.5×12 cm. The naturalness of the cladding is given by corner elements made using the same technology. The front side is stylized to resemble the structure of a brick, and is given a certain roughness and uneven color.

Very often tiles are made from porcelain stoneware large sizes imitating natural stone, for example granite, travertine or sandstone, as well as torn brick front surface. The price of imported porcelain stoneware brick tiles starts from 1900 rubles per 1 m2. The cost of domestically produced products starts from 800 rubles.

The tiles are attached to the wall surface wet method. That is, on a pre-leveled solid base, the products are fixed using special adhesive mixtures. It is not advisable to use small-sized tiles for arranging ventilated facades. For this purpose, products with large dimensions are used that imitate a natural stone with a polished or textured surface.

Clinker tiles are formed from a raw mass and fired at high temperature within 36 hours. Clinker was originally intended for use outdoors and resists well almost all destructive weather influences: rain, frost, wind and sun.

The use of clinker tiles significantly reduces the cost of building a new house. Its advantage is that it can be used to decorate walls made of gas and foam blocks. It is also easy to use clinker to renovate the façade of an old building. There is only one important condition To use clinker tiles, namely, the walls of the building must be pre-leveled, there should not be any looseness or crumbling plaster on them.

The variety of colors of clinker tiles provides ample opportunities in creating designs and making decorative dressings and combining colors. Laying is done in a thin layer glue mixture directly onto the wall or onto high-density mesh-reinforced insulation.

The price of brick-like facade tiles from the German manufacturer Stroeher ranges from 1900 to 2660 rubles per 1 m2, depending on the type of treatment and surface texture. Cheap Russian-made tiles are 2-3 times cheaper. Products measuring 240x60x6 cm can be purchased at a price of 650 rubles per 1 m2.

You can learn more about the features of laying tiles under brick in the following video:

,

Thermal panels combine three types of building materials:

In most cases, extruded polystyrene foam is used as insulation. The front side of the panels can be lined with plastic, metal or ceramics. Finishing with porcelain stoneware or clinker imitates wild stone or brick standard sizes, different shades and textures.

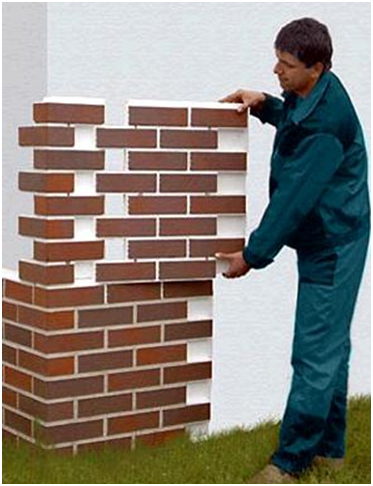

The panels are made in such a way that individual bricks protrude from the sides. Subsequently, during installation, they are joined according to the principle of the designer, thereby ensuring the reliability of laying the material. In the photo below you can see how the assembly process occurs.

Advantages of using thermal panels in facade finishing:

To cover the facade with panels, the walls are leveled with mortar or sheathing is mounted on them. On brick and concrete surfaces Thermal panels are fastened with dowel-nails with a length of 120 mm, and on a wooden sheathing they are fastened with anodized self-tapping screws with a length of 100 mm. Installation begins with the corner elements from the base, leaving a distance between the panels equal to the width of the seam between the individual bricks.

The main share of the cost of thermal panels is determined by the finishing material front side and manufacturer's brand. Products from Dutch, German and Finnish manufacturers predominantly use clinker coating. Their cost is from 2500 rubles per 1 m2. Thermal panels from Poland are a little cheaper, their price varies from 1200 to 1700 rubles per 1 m2. Russian facing material can be purchased inexpensively even with high-quality ceramic coating, price range - from 800 to 1000 rubles per 1 m 2.

Most cheap option thermal panels up to 600 rubles per 1 m 2 with plastic coating. They are used for insulation and improvement of old buildings and apartments in multi-storey buildings. Panels are produced in the form of rectangular or square blocks of various colors with brick-like seams. This type of material is perceived as brickwork only when looking at the building from a distance.

Brick-like facade tiles allow you to realize the most original ideas when facing facades. At the same time, its diversity allows it to satisfy the price requirements of buyers of various categories.

Often decorative rock appears under the name brick facing tiles due to its size and small thickness. This kind finishing material used in cases where the use of conventional facing bricks does not seem possible. Besides this type The material is used to style buildings as brick: such tiles completely imitate masonry, while they are much cheaper and lighter than their natural counterpart. Leonardo Stone offers its customers various series of brick-like facing tiles, which you can find in the “Products” section.

A brick facade is very beautiful, but not always the owner of a building can afford to cover his house with brick. Sometimes this requires building an additional foundation or strengthening existing structures. And sometimes there is not enough money to buy ceramic bricks. In all these cases, brick-like facing tiles can come to the rescue.

This type of tile comes the following types:

This material, laid out on the walls of a building, looks like real brick. However, compared to brick, tiles have many advantages:

In our product catalog in Moscow you will find several collections of brick-like facing tiles that will help create the complete illusion brickwork. You can choose the tile color that best suits your design ideas. If you have any difficulties making a choice, our consultants will help you decide. If necessary, you can order from us not only the material itself, but also installation services. Our professionals will do your cladding quickly, efficiently and inexpensively.

Brick-like facade tiles are a type of facade tile. Facing facade tiles imitated brick is distinguished by a variety of colors and surface types. It is important to note that with its front surface the façade tiles are absolutely similar to the front bricks from the same series and have similar technical characteristics. Brick-like facade tiles include several types of outwardly similar products that differ in manufacturing method, raw materials, technical parameters and subdivided into the following main types of facade tiles for brick - ceramic facade clinker tiles for brick; concrete facade hyper-pressed brick-like tiles (facade tiles “torn stone”); hand-molded ceramic facade tiles imitating bricks (antique facade tiles).

to his appearance and technical characteristics, facade brick tiles are almost completely identical to facade facing bricks. The only significant difference between facing brick tiles and facade facing bricks is the size of the product and its weight, for standard facing bricks the width of the product is approximately 115-120 mm, for brick tiles the width is usually from 9 to 14 mm, the difference in these parameters certainly affects the weight of the product. Parameters such as height and length are almost identical for facing bricks and brick-like façade tiles. Using brick-like façade tiles, as well as facing bricks, you can decorate the façade of a house according to the “Bavarian masonry” principle. Finishing according to the “Bavarian masonry” type involves the simultaneous use of finishing materials of brown and red colors in an arbitrary geometric pattern. The type of masonry “Bavarian masonry” is currently very popular in Russia and Europe.

Clinker facade tiles for brick look

Facade clinker tiles

brick-like is a type of brick-like facade facing tiles used for finishing the facades of houses, buildings and structures, which has the highest strength, frost resistance, rich color that does not change over time, and the ability to not absorb and repel moisture. The water absorption coefficient of facade clinker tiles for brick is less than 6%.

Facade clinker tiles

brick-like is a type of brick-like facade facing tiles used for finishing the facades of houses, buildings and structures, which has the highest strength, frost resistance, rich color that does not change over time, and the ability to not absorb and repel moisture. The water absorption coefficient of facade clinker tiles for brick is less than 6%.

Clinker tiles for bricks have the same dimensions as facing

, but differs from clinker bricks in its thickness; as a rule, the thickness of clinker tiles for bricks is 9-14 mm.

Facade brick-like clinker tiles are used for cladding building facades and finishing interior walls premises to give the interior an original look.

It is especially necessary to highlight brick-like clinker tiles from Germany, which are widely represented on Russian market.

from Germany is different highest quality products and variety of colors. Sales volumes of Feldhaus Klinker facade clinker tiles for bricks are steadily increasing every year in Russia. The German concern produces not only clinker tiles, but also facing and paving

. Among the types of clinker presented in Russia from Europe, Feldhaus clinker is one of the bright leaders in sales of clinker - facade clinker tiles for bricks, paving clinker bricks and facing clinker bricks.

Facade brick-like clinker tiles have the following technical characteristics:

|

Manufacturer |

Weight, kg/piece |

Size, mm |

Consumption pieces/m2 |

Water burnishing |

Frost resistance |

Purpose of clinker tiles |

|

Feldhaus |

0,364 |

240x71x9 |

300 cycles |

Facade cladding |

||

|

Robin |

0,54 |

240x71x14 |

300 cycles |

Facade cladding |

||

|

ABC |

0,354 |

240x71x10 |

300 cycles |

Facade cladding |

Facade clinker tiles imitating bricks are also used for cladding facades. thermal panels, in which the insulation is polystyrene foam, and facing material brick-like façade tiles. Facade thermal panels with brick-like clinker tiles allow you to quickly cladding and at the same time insulate the facades of houses. Facade thermal panels can be bought wholesale and retail in finished form with brick-like facade tiles already glued to the insulation, or separately - a thermal panel, brick-like facade clinker tiles and glue, in this case the facade clinker tiles are glued independently. The kits include dowels for fastening to the wall and special grout for the seams between brick-like clinker tiles. In Russia, the following types of facade panels are most often found on sale: “Europe” facade panels, REHAUS facade panels with facade clinker ABC brick tiles and KamphaTherm façade panels with Feldhaus Klinker brick-look clinker tiles. Without preparatory work thermal panels with guides are attached with universal dowels directly to external wall. In this case, labor-intensive work on the construction of the foundation is eliminated and, as a rule, there is no need to lengthen the roof overhangs above the gable and the eaves overhangs.

Facade clinker tiles imitating bricks are also used for cladding facades. thermal panels, in which the insulation is polystyrene foam, and facing material brick-like façade tiles. Facade thermal panels with brick-like clinker tiles allow you to quickly cladding and at the same time insulate the facades of houses. Facade thermal panels can be bought wholesale and retail in finished form with brick-like facade tiles already glued to the insulation, or separately - a thermal panel, brick-like facade clinker tiles and glue, in this case the facade clinker tiles are glued independently. The kits include dowels for fastening to the wall and special grout for the seams between brick-like clinker tiles. In Russia, the following types of facade panels are most often found on sale: “Europe” facade panels, REHAUS facade panels with facade clinker ABC brick tiles and KamphaTherm façade panels with Feldhaus Klinker brick-look clinker tiles. Without preparatory work thermal panels with guides are attached with universal dowels directly to external wall. In this case, labor-intensive work on the construction of the foundation is eliminated and, as a rule, there is no need to lengthen the roof overhangs above the gable and the eaves overhangs.

Cladding and insulation of the facade with an insulation system using KamphaTherm panels with clinker facing brick-like facade tiles Feldhaus Klinker, Europe and Rehaus panels with brick-like clinker tiles ABC from Germany and others facade panels, provides excellent protection of house facades from moisture penetration, maintains density during heavy rains, but allows the diffusion of vapor from the room to the outside, i.e. is vapor permeable. This helps to avoid damage due to sweating and keeps clinker tiles for bricks and other expensive items intact. Construction Materials over a long period of time. Repair of the facade will be needed only after tens of years!!!

Hand-molded brick-like facade tiles

Hand-molded facade tiles imitating bricks (antique facade tiles) are a type of facade clinker tiles imitating bricks. Currently to receive brick facade made from hand-molded bricks, it is not at all necessary to use a solid ceramic façade cladding hand molded brick- this is not always advisable for economic and design reasons. Therefore, more and more often, to imitate a facade made of facade decorative facing clinker bricks, Customers use the material - decorative facade facing clinker tiles to resemble bricks and hand-molded clinker tiles from Germany. An excellent alternative to hand-molded full-size facing bricks is facade tiles for hand-molded bricks, for example, made either by extrusion or by mechanical separation (by chipping or sawing off) the decorative facade part of the brick. With the first production option - extrusion, hand-molded facade brick tiles have a thickness of no more than 12-14 mm, while with mechanical separation of facade tiles, their thickness is 22-25 mm. Facade decorative tiles manual molding to look like a brick is made by cutting off the front part of a hand-molded brick.

Hand-molded facade tiles imitating bricks (antique facade tiles) are a type of facade clinker tiles imitating bricks. Currently to receive brick facade made from hand-molded bricks, it is not at all necessary to use a solid ceramic façade cladding hand molded brick- this is not always advisable for economic and design reasons. Therefore, more and more often, to imitate a facade made of facade decorative facing clinker bricks, Customers use the material - decorative facade facing clinker tiles to resemble bricks and hand-molded clinker tiles from Germany. An excellent alternative to hand-molded full-size facing bricks is facade tiles for hand-molded bricks, for example, made either by extrusion or by mechanical separation (by chipping or sawing off) the decorative facade part of the brick. With the first production option - extrusion, hand-molded facade brick tiles have a thickness of no more than 12-14 mm, while with mechanical separation of facade tiles, their thickness is 22-25 mm. Facade decorative tiles manual molding to look like a brick is made by cutting off the front part of a hand-molded brick.

In this case, brick tiles and hand-molded bricks have the same surface and do not differ from real hand-molded bricks.

Also, the corners of the tiles are cut from solid hand-molded bricks, this allows you to produce a house facade, the appearance of which is in no way different from a full-size brick facade, lined with hand-molded bricks.

Hyper-pressed brick-like facade tiles

Thanks to the wide range of colors and texture of the front surface of the façade, which is also called façade concrete tiles, it makes any structure unique.

Thanks to the wide range of colors and texture of the front surface of the façade, which is also called façade concrete tiles, it makes any structure unique.

In the production of facing concrete hyperpressed tiles, only environmentally friendly materials are used. clean materials: cement, crushed limestone, dolomite, pigments approved for use in the production of building materials and quite resistant to harmful effects environment. Facing hyper-pressed brick-like tiles are distinguished by the exact shape of the product and the unusual texture of the front surface - facade hyper-pressed tiles “like torn stone”.

Great combination color range facing brick-like facade tiles using the hyper-pressing method, its durability and water-repellency and low weight make it possible to use hyper-pressed concrete tiles under brick for cladding facades, external and internal walls of buildings, cladding fences and other small architectural forms.

Thanks to the perfect hyper-pressing system, brick-like facing tiles, as well as facing hyperpressed brick, stands out good quality and stable characteristics, such as frost resistance (F-75), strength (M-300), moisture absorption (no more than 6.3% - the likelihood of efflorescence formation is reduced). It is important to note that, if necessary, you can improve all quality indicators and make hyper-pressed concrete facade tiles to look like brick in any color.

Semi-dry hyperpressing of facade tiles is based on the process " cold welding", which occurs when pressing finely ground limestone or dolomite rock under high pressure. The addition of water and cement as a binder material allows you to bring the required pressing pressure and grinding depth to technically and economically acceptable limits. Facade facing hyperpressed brick tiles are produced by cutting the front parts from hyper-pressed facing bricks or, if appropriate equipment is available, by separate hyper-pressing of facade tile blanks. atmospheric exposure and to give the house aesthetic appeal. Houses lined with façade hyper-pressed tiles imitating brick are distinguished by their appearance and infinity of architectural and aesthetic solutions. Yellow Red, Brown color in combination with the front surface of hyper-pressed tiles, “torn stone” (similar to crushed brick) gives each home its own uniqueness.

Wide range of colors and mechanical chipping technology on façade hyper-pressed tiles (decoration like “torn stone”) - a real find for any designer and architect. In Europe, hyperpressing technology has been successfully used for more than ten years, thanks to the beauty and durability of the products.

The use of mechanical chipping technology on brick-like façade tiles allows us to obtain a unique texture for each brick. The high strength, frost resistance, erosion resistance and durability of hyper-pressed facing brick tiles make it possible to decorate building facades in various climatic zones.

- This stylish solution for any interior. IN Lately design using such material is becoming increasingly popular (it has even been called “loft”).

However, the brick itself still makes the surface heavier, requires certain knowledge in masonry and “steals” some of the space in the room. A much more convenient analogue in this regard is a tile that imitates it.

First of all, such a presentation is interesting because it allows you to get away from standard templates. The use of such tiles will help create a unique and inimitable interior.

Besides this, there are other advantages:

The material is truly harmoniously suitable for any interior. It will allow you to realize any designer’s fantasy. Most often, such tiles are used to stylize a variety of historical styles. Big choice The area of use also represents - it starts from the hallway and will look completely complete even in bedrooms.

The modern market offers several options for such cladding solutions. Among them, the most relevant will be the following:

The choice of each of them will be determined by the goals set. Depending on the characteristics of the chosen type.

Decorative gypsum tiles for brick look is a true leader in internal lining. It meets all the stated requirements, and even a beginner can handle the installation of such a coating. Its perfection is outweighed by only two disadvantages - fragility and water permeability. However, here you can find a way out: the blocks are reinforced and coated with a special compound that has hydrophobic properties. (more details about the surface here)

Definitely, this option is only a facing tile underneath (it will look great, for example, on fireplace structures).

In contrast to the considered ceramic- this is already a brick-like facing tile for exterior finishing(although it is also successfully used indoors). It also has environmentally friendly origin and high tensile strength. There is an additional advantage here - the material does not conduct current.

Clinker facing tiles for brick facades more often relevant when working with the foundation. This type does not require any special care, but despite this, it is very durable. The whole secret is in the production technology: production is carried out by firing clay (special varieties are taken). Thanks to this method, the material will not contain any voids or inclusions.

They look quite nice, made to look like brick. Or option. Video link.

The installation of such tiles is somewhat similar to the work of laying tiles. But there are some peculiarities here that must be taken into account. In general, the work algorithm will be as follows:

There is another styling method - “dry”. It is customary to use facing blocks, which have protrusions. In this case, slats are attached to the wall, with a step that is equal to the tile width. In the future, gypsum block protrusions will be placed between them and the wall. The work occurs in a vertical order and starts from the corner. The slats themselves will perfectly hide the seams.

More on the topic: