Wooden windows have always been popular, which is due not only to their excellent appearance, but also the environmental friendliness of the materials used. A homemade window can be easily assembled at home. To do this, you need to have minimal experience working with wood and a set of tools. The process doesn’t take much time, but the end result is beautiful and stylish. wooden window, which, after assembly, can be painted in the chosen color or covered with scrap stain and varnish.

To make homemade wooden windows with your own hands, you need to prepare the tools that will be needed during assembly:

Technology for installing a wooden window using mounting blocks.

Should be prepared wooden beam or strips of moisture-resistant plywood, special wood glue, self-tapping screws, metal corners, glass. For bars, it is best to take a cross-section of 50*150 mm or 50*50 mm. Before choosing the sizes of boards or plywood, you need to draw up a drawing. It will help you correctly calculate the materials, determine what thickness will be optimal, and what amount of glass is best to use for a particular case.

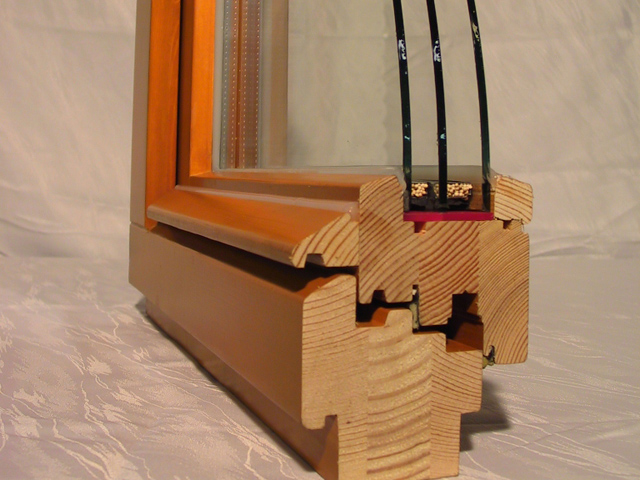

To make the frame, it is recommended to use laminated wood, that is, bars that are connected to each other with wood glue. The result is a beautiful and durable window. It will last for decades. Glued laminated timber is practically not subject to negative influences, including changes in temperature and humidity. This is very important for a window, since its deformation, for example, makes it impossible to open the sash. Glued laminated timber today is a common material in construction: houses are built from it and reliable floors are made from it.

You can also take ordinary timber, but you must remember that its service life is shorter. It can quickly become deformed from moisture and negative atmospheric conditions. The service life for a window made of ordinary timber will be shorter than for a window made of laminated veneer lumber. It is necessary to prepare the wood in advance; laminated veneer lumber is easy to buy ready-made. It only needs to be treated with an antiseptic and fire retardant. After this, the tree is left to dry completely.

Return to contents

![]()

How to make a homemade window from wood? The technology of work is as follows:

After the frame is ready, you need to insert the glass using a special putty, which will not be visible from the outside. Carefully connect the frame and box using self-tapping screws and glue. When it dries, the finished wooden frame can be painted with paint of the chosen color. There is another method that allows you to preserve the natural beauty of wood, this is the use of varnish or oil.

Despite the significant popularization of PVC structures, wooden double-glazed windows still remain one of the most popular technologies used today in domestic construction. Wood, as an environmentally friendly material, not only has a beneficial effect on the internal microclimate of the room, but also solves one of the most big problems plastic - formation of local greenhouse effect. The layered structure of the natural material does not in any way interfere with air microcirculation, thereby preventing the formation of condensation.

Thanks to the significant development of production technologies, modern wooden double-glazed windows have a number of properties that set them apart from all other structures. For example, the most popular models of wooden windows are treated with a special compound that protects the product from biological and chemical influences.

Surprisingly, despite all its complexity, wooden double-glazed windows can also be produced at home. To do this, you need to have certain skills in woodworking and stock up on the appropriate tools.

Producing wooden double-glazed windows on your own will require the following tools:

It should be noted that for the manufacture of a wooden double-glazed window frame, enough wide range wood species, which significantly influences the choice of tools. For example, oak has such dense wood that it will be difficult to process it by hand.

The process of manufacturing a frame for a wooden double-glazed window can be considered the most labor-intensive stage. First of all, it is necessary to take accurate measurements of each window opening. This is done in order to eliminate the possibility of non-compliance standard size frames custom sizes window opening. Thus, for each double-glazed window, its own frame is developed according to individual dimensions.

Traditionally fastening beams wooden frame produced using tongue-and-groove technology. To do this, a groove is drilled in the vertical posts, into which a tenon from the horizontal post will subsequently be installed. The depth of the grooves is determined based on the width of the timber used.

The whole process looks like this:

Next, the entire structure is assembled using wood glue. The increased size of the tenon ensures its tight fixation in the groove even without glue, and all excess binder must be removed before it hardens completely.

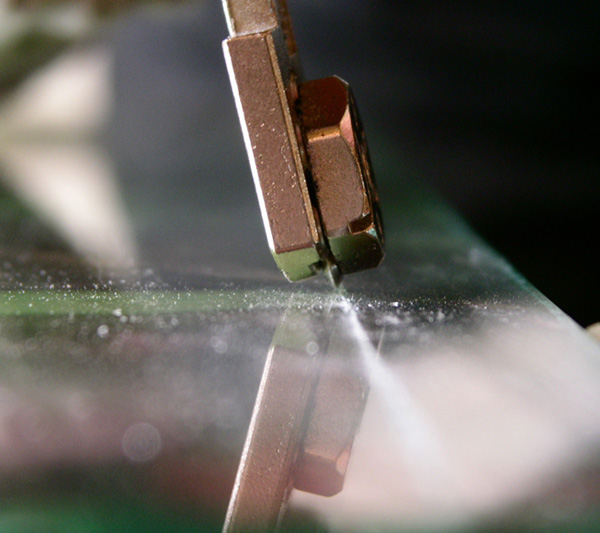

By analogy with a frame, the production stage of a double-glazed window begins with precise markings. Even a deviation of 1 mm is considered unacceptable, which is why the following standards must be strictly observed when cutting glass:

The final assembly of the product is carried out only after several fitting stages. This is done in order to eliminate all inaccuracies made during the manufacture of parts. If the design is ideal, sealant is placed in the grooves for the glass and installed, followed by fixation with putty. In general, this procedure is not much different from the modern assembly of a simple wooden window.

It is important to note that in industrial production wooden double glazed windows Silica gel is used to remove moisture between the glasses. You can find it at a hardware store.

Varnish or paint will provide additional protection to the window frame. They should be applied some time after assembling the structure. And only after drying paint coating You can proceed to installing the fittings.

Nowadays people value environmentally friendly clean materials. Many of us are rather than plastic. The tree itself is natural material. Such windows are warm and do not allow drafts to pass through. Unlike their plastic counterparts, wooden ones allow the apartment to “breathe”. In our article we will look at all the advantages and specifications such windows. Let's get acquainted with various master classes and learn how to make and repair old wooden windows.

Wooden windows with double glazing differ from plastic products the following features:

If desired, you can order frames of any size, shape and shade.

Anyone can buy such windows. In some cases, the price is more expensive than plastic. The cost is calculated based on the following criteria:

If you want to save on buying wooden windows, then you should consider the option of one or double-glazed windows. They will also keep the apartment warm well and block out extraneous noise from the street. The latest technologies make it possible to improve the thermal insulation of windows. To do this, insert double-glazed windows covered special paint, which increases energy saving. Hardwoods, such as oak or pine, are used to make frames. A ready-made double-glazed window is inserted into them aluminum profile. The space between the glasses is filled with inert gas. This is what makes the window soundproof. Silica gel is used to seal seams.

The window market has been replenished with examples of Finnish production. They differ from our analogues in their design.

Finnish glazing system

Let's look at it in more detail. Finnish wooden windows with double-glazed windows for an apartment consist of two sashes, which are connected to each other by fastening elements. In one half of the window there is a double-glazed window, in the other - ordinary glass. They are divided into two types of opening:

To make it easier to ventilate the room, the window design is complicated and supplemented with vents.

Finnish window

You can find Finnish combined type frames on sale. Such windows use not only wood, but also aluminum. They will fit perfectly into any interior. Such windows have their advantages:

Windows can be made to order in any size. The unique design reduces the load on the load-bearing parts of the frame when opening.

Different shapes of wooden windows

Like this positive characteristics have foreign-made windows. Such equipment is installed in an apartment or in a private house. But there are places where you cannot install such expensive windows. You can make wooden windows with double-glazed windows inexpensively with your own hands. For a summer residence, this is the most economical option.

To get your dacha you need to prepare the following tools:

We make it according to the size of the window opening. We install it. He must stand motionless in it. It is secured with self-tapping screws. We fill all the gaps between the box and the opening polyurethane foam. But there are some nuances here too. During the drying stage of the foam, it happens that it may increase in size. Because of this, the frame may move and the window will become bent. Accordingly, such a design cannot be left. The foam is replaced with another material, for example, tow. It can very well plug up all the free space, and it is also a good insulator.

This is the second stage of window manufacturing. The design of the frame is similar to a box, only a pin and a corner are used for connection.

Wooden frames

They are needed to give the frame strength and reliability, which is important when constantly opening and closing the window. Prepare a beam for making the frame, which should have a groove for inserting a double-glazed window. To make it, you can use a router or an electric plane. We make the groove strictly to size. It is recommended to connect the parts together using the tongue-and-groove technique. Once you have assembled the entire frame, check that everything is connected at right angles. Don't forget to attach metal corners at the ends. Let's move on to the next stage.

It is worth mentioning right away that double-glazed windows can be ordered from a company that specializes in windows or purchased from glass manufacturers in your city. The package must be made based on the dimensions of the frame. If you live in a country house only in summer period, then installing single-chamber glass is sufficient. If you plan to live there all year round, then you have a choice of two or three chamber glasses. We insert the glass unit into the grooves prepared in advance. We secure them with glazing beads. And now our window is almost ready. The very last stage is wood processing. This can be done using a special colorless varnish or drying oil. These materials favorably emphasize the natural texture of wood.

We looked at a master class on how to make a wooden window with your own hands. Step-by-step instruction, the video below will help you study each stage in more detail.

Through-mounting of a wooden window

But what about old windows? Don't rush and throw them away. Let's study in detail the question of how to update old wooden windows.

Assess the condition of your frames. Visually inspect for cracks in the wood and deterioration of the paint. If the glass is loose, then it should be fixed using special glue, or you can simply change the beads. The frame can be updated by painting.

You can do this in two ways:

We will consider all options. Restoring wooden windows with your own hands will cost inexpensively and quickly using the first method, but of poor quality. Fresh paint will peel off quickly. And everything will have to be redone again. Still, it’s worth spending a little more time and doing quality work. If you are still interested in the question of how to paint wooden windows using old paint? It's easy to do. Wash the frames from dust, dry and paint. But good result you are not guaranteed.

You can do the job in different ways:

You can't start painting yet. Examine the tree. If there are cracks, they should be repaired. To do this, we use the following solution: stir wood sawdust in PVA glue. Seal all cracks and holes with it. Now you need to wash the frames from dust and dirt and dry them well. Consider factors such as weather when painting. It is not recommended to paint frames that have become very hot in the sun. You shouldn't do this in the evening either. Do-it-yourself painting of wooden windows should be done in daytime day, in slightly cloudy weather. This will help maintain all the protective properties of the paint.

Updating wooden frames

Among all the diversity paint and varnish materials Acrylic paint is best suited. When used, it is completely safe and does not emit a strong toxic odor. Dries quickly. Easily wipes off skin and washes off clothes. And its technical characteristics are simply excellent. Acrylic paint easy and simple to apply. If you paint the frames with a thick layer, it will perfectly protect the wood from temperature changes and high humidity. Lasts a long time.

All old handles and hinges are subject to inspection. They can be cleaned if necessary. If this is not impossible, then we simply replace them with new fasteners. We reviewed the full algorithm of actions and found out how to repair wooden windows with your own hands; the video that you will find on our website will show all the work from start to finish.

These days everything more people prefer modern wooden windows with double-glazed windows. Despite them high cost, they are gradually starting to displace their PVC competitors. Wooden windows can be combined with various designer interiors. If desired window frames made in any shade. To summarize, we can safely say that wooden windows are much warmer and more comfortable. They allow us to live ecologically clean houses and apartments. Breathe fresh air. You should not save on the health of your loved ones. Such windows will serve you for a long time. If necessary, you can make a restoration and give them a second life. If you want to save money, make the windows in your house yourself.

If you want to glaze any room yourself, then the best way is the production of homemade windows from wood. But how to make them? Let's consider!

Hinge mounting

You will need a whole arsenal of carpentry tools, and among them:

It would be just a gift if you had a power tool: a cutter, a “bee”, an electric chisel, etc., but if you don’t have them, you shouldn’t be upset, what you have will do.

In order for a homemade window to be of high quality, you need to carefully approach such an issue as the choice of material. It is optimal, of course, to choose pine, since it is easy to process and can be used quite well, but the choice, of course, is yours.

Real wooden double glazing

In addition, we would advise you to purchase laminated veneer lumber, since it is much better prepared for use than solid wood.

Before you start cutting, you should carefully measure the opening and determine for yourself how wide the frame you will make. Moreover, keep this point in mind: in cross-section, the frame should represent the letter “G”, that is, the doors will open inward, and it will be the top of the letter that will hold them back from the outside.

So, having decided on the dimensions, proceed to cutting. Here you can work with whatever is more convenient for you, as long as the dimensions are accurately observed, since then it will be easier for you to join the sashes and double-glazed windows under the frame.

To fasten vertical and horizontal elements, use tongue-and-groove fasteners.

Important! The length of the “tenon” should be no less than the width of the frame, and the tenon should also be slightly larger than the corresponding groove.

Then you sand the frame itself; if necessary, you can putty some places with a mixture of sawdust and epoxy. Let it dry, then sand again. If you want the surface to be smooth and silky afterwards, then you should purchase a primer that lifts the pile. Apply it, let it dry and remove any raised lint with sandpaper. Then re-apply the primer and sand it completely.

For this you need to prepare a cutter. You will need to carve a multi-stage structure from a block. Look, the first step is under the glazing beads that will press the glass, the second step is under the glass itself. Now look, in the riser of this step you will need to make a recess along the entire length, where either a seal will be placed, or, in our case, silicone will be squeezed out.

Seal installation

The distance between the glasses should be at least 1 centimeter. We will again fasten the horizontal and vertical elements with a tongue-and-groove connection; in addition, you can coat these parts with wood glue, then the structure will be stronger.

So, the base of a homemade double-glazed window is ready.

Important! You can’t drive “back and forth”, there must be only one movement!

If your sashes are blind, then first the base for the double-glazed window is attached to the main frame, and then the glass is attached to it. And if they open, then first you will need to make a double-glazed window for a homemade window.

To do this, first insert the glass there, see if it needs cutting somewhere? If not, then pull it out and apply silicone into the “riser” groove along the entire length, and only then carefully place the glass on top.

Important! Don't overdo it with silicone!

Now your double-glazed window is ready. All that’s left to do is install hinges on the main frame and adjust the sash so that it moves without touching the elements.

So, this is how homemade wooden windows are made, we are sure you will succeed! And if you take it into account, then the window will serve you for decades.