Due to the fact that the range of insulation materials on the market building materials, very large - each consumer can choose the type of insulation that suits him.

One of these insulation materials is penoplex. It's synthetic insulating material for internal and external insulation.

All of these qualities give penoplex versatility of use and allow it to stand out among other insulation materials. It is produced in the form of sheets, which consist of polystyrene foam pressed under high temperature.

Penoplex sheets have a little more weight than regular foam, but the thickness is the same: 20 mm, 30 mm, 40 mm, 50 mm. Most often, the thickness of penoplex determines the area of its application.

Note: There are no locks for installation on sheets with a thickness of 20 mm; they are provided for sheets with a thickness of 30 mm or more.

The use of penoplex has fairly high quality indicators, but will not be available to everyone, since the price of such insulation is several times higher than the price of all similar products (foam 25 or 35 density).

To carry out the work you will need:

All types of penoplex and any thickness are used for walls. The choice will depend on the financial capabilities of the consumer and the characteristics of the building itself.

Note: insulation should be reinforced with façade plastic mesh which will keep decorative finishing and will protect it from blow-outs and chips.

This insulation option provides:

Take note: To insulate the base, penoplex with a thickness of 40-50 mm is used for maximum protection.

The most heat is lost through the part of the house that is closest to the ground - the foundation, so its insulation requires a special approach, and penoplex will be the ideal material for this.

The process of carrying out work on insulating the underground part of a building is very simple:

It is best to use penoplex for insulation maximum thickness- 50 mm.

This part of the apartment is responsible for preserving the heat that escapes through balcony block, so here you need to act with full responsibility.

Work on insulating a balcony with penoplex is carried out in stages:

When using PVC or MDF lining the process will be slightly different:

Take note: To insulate the balcony, penoplex with a thickness of 20 or 30 mm is used to increase the usable area.

Extruded polystyrene foam occurs by joining sheets using existing grooves.

Note: According to the technology, the entire insulation is covered with a waterproofing film, which is very rarely done by craftsmen due to the inconvenience of installing the screed. Next comes the reinforced layer - masonry mesh, which is laid over the entire surface to be reinforced, and everything is poured cement screed for the floor.

If you plan to install a wooden floor, then sheets of Penonlex are laid between the joists, having previously covered the floor with a waterproofing film.

Installing a heated floor with insulation such as penoplex is completely safe even without the use of additional insulation.

Floor insulation in apartment building will also create an additional layer of sound insulation. It is advisable to use insulation sheets of maximum thickness - 40-50 mm.

Considering all of the above, we can conclude that such insulation as penoplex can be used in any premises and under any conditions. weather conditions. The options described are not all; for example, penoplex can be used to insulate even a garage. The only condition will be the thickness of the foam sheet, on which the quality of the insulated surface directly depends.

We bring to your attention a comparison video different types penoplex:

Below is a list of frequently asked questions and answers related to PENOPLEX ® thermal insulation:

PENOPLEX ® boards and expanded polystyrene (PSB) differ in their production technology. Pressless polystyrene foam is created by “steaming” microgranules with water vapor in special form and their increase under the influence of temperature. Thermal insulation PENOPLEX ® is made by mixing polystyrene granules at elevated temperature and pressure with the introduction of a foaming agent and subsequent extrusion from the extruder. That is why PENOPLEX ® expanded polystyrene is called extruded. Also, thanks to the production technology using this technology, PENOPLEX ® receives a closed, fine-porous structure, which in turn ensures high strength, almost zero water absorption, as a result - biostability and the highest durability of PENOPLEX ® boards. An important factor Also, the thermal conductivity of PENOPLEX ® is lower compared to pressless polystyrene foam (PSB), which makes it possible to reduce the thickness of the required thermal insulation by approximately 30%.

What is better PENOPLEX ® or mineral wool? This is a question that arises quite often among private developers. Each of these materials has its advantages. For example, PENOPLEX ® is practically indispensable in loaded structures and humid environments, while mineral wool performs better in sound insulation. In addition, some types mineral wool have more low price, but this advantage often comes to naught due to the low quality of such wool, as a result - large shrinkage, as well as the need for greater thickness of thermal insulation.

PENOPLEX ® is distinguished from mineral wool by a number of characteristics:

- lower thermal conductivity coefficient.

- high compressive strength

- absolute moisture resistance (PENOPLEX ® does not absorb water, due to which it retains its thermal insulation properties throughout its entire service life).

- absolute biostability (PENOPLEX ® is not a matrix for the development of bacteria, mold and other microorganisms).

- ease of installation (PENOPLEX ® does not require special means protection when working with it).

The density of PENOPLEX ® boards for private use ranges from 23 to 35 kg/m3. For the professional segment, this figure can reach up to 45 kg/m3. It is important to understand that the density of PENOPLEX ® is not a key factor in determining the scope of application of the material. A more important characteristic is compressive strength. The strength characteristics of PENOPLEX ® vary over a wider range. The minimum compressive strength at 10% deformation for PENOPLEX ® slabs is 0.12 MPa; such slabs are used for non-load-bearing structures (for example, for wall insulation). The slabs intended for insulation of foundations have higher compressive strength values - 0.3 MPa, since it is these structures that bear the main loads from the building. PENOLEX ® grades intended for road construction and structures with increased loads can have a strength of 0.50 MPa and higher.

Wide range characteristics allows the use of PENOPLEX ® slabs for insulation of almost any structures, both in cottage and low-rise buildings, as well as in industrial and civil construction.

The temperature range for use of PENOPLEX ® boards is in the range from -70 to +75 degrees Celsius, which allows the use this material in any climatic zones.

At temperatures above 75 degrees Celsius PENOPLEX ® can change its mechanical properties towards decreasing the strength of the material.

If we compare materials in terms of thermal insulation properties, a PENOPLEX ® slab with a thickness of 50 mm (λ = 0.034 W/m2°C) will replace 1280 mm of masonry on a thermal insulating mortar made of solid single brick (λ = 0.82 W/m2°C). (According to GOST 530-2012 Ceramic brick and stone. General technical specifications. Table D.1 - Thermal characteristics of solid (conditional) masonry).

On average, in terms of thermal insulation properties, 1 cm of PENOPLEX ® replaces 25 cm brickwork, but you should remember - for each individual type of brick (silicate, ceramic, clinker) this comparison will be different.

When constructing buildings and planning thermal insulation work, the question often arises of replacing expensive building materials with cheaper analogues. In the case of brick wall cladding, developers offer as budget option use Penoplex. Although both materials are used for external masonry, their comparison can be made only by thermal conductivity. Based on the thermal insulation properties, a calculation is made of the required quantity to replace the brick.

“Penoplex” is the name of popular slabs of extruded polystyrene foam, used for insulating structures of any kind.

The technical characteristics of the material are as follows:

In terms of thermal conductivity, foam plastic clearly prevails over brick. Thermal indicators silicate brickwork is 0.76 W/m2°C, solid ceramic - 0.7. This is provided that the space between the bricks is filled with cement-sand mortar: in comparison with others construction mixtures a base of cement and sand provides the greatest thermal insulation. The indicators for polystyrene foam are as follows: Penoplex block 50 mm - 0.038 W/m2°C, 30 mm - 0.037. The figures given are approximate.

This material can be used to insulate walls.

This material can be used to insulate walls. "Penoplex" can be used for thermal insulation, both external and inside walls However, expanded polystyrene is not recommended for insulating chimneys: the material cannot withstand extremely high temperatures, which can result in a fire. For installation, either special cement-based adhesive mixtures or umbrella-shaped dowels are usually used.

Calculation of the replacement of building stone with expanded polystyrene is carried out from the ratio of the results of multiplication (separately for brick and foam) of heat transfer resistance to thermal conductivity. It is believed that an acceptable figure for non-industrial buildings is 2.1 m2°C/W heat transfer resistance. So, for brickwork, multiplying averages thermal insulation characteristics gives the following thickness: 2.1×0.7 W/m2°C = 1.47 m. In the case of Penoplex with a density of 30 kg/m3: 2.1×0.037 = 0.077 meters. When compared to building stone (1.47/0.077), it turns out that approximately 19 times less polystyrene foam is needed. So brick and Penoplex will have the same thermal insulation characteristics.

In order not to bother with calculations, there is an approximate ratio for replacing building stone with polystyrene foam. It is possible to replace 370 mm with a foam block 2 cm thick brick wall. Saving material costs is at least 150 rubles per square meter cladding. “Penoplex” 30 mm replaces brick by almost 6 cm. If the thickness of “Penoplex” is 50 millimeters, the equivalent of brickwork is 9.25 centimeters.

Of modern thermal insulators, penoplex is considered the most effective. This insulation material is made from extruded polystyrene, which automatically makes it cheap, but superior in technical specifications, such as moisture absorption and sound insulation, other heat insulators.

The production of penoplex is organized using the following technology: small polystyrene granules in a sealed chamber are exposed to high temperatures (130 0 C-140 0 C), as a result of which they melt, and after adding blowing agents they foam. Porophores are synthetic additives that, when heated, release nitrogen and carbon dioxide, turning after the penoplex cools into frozen air bubbles, evenly distributed throughout the material.

Components of blowing agents for the production of extruded polystyrene foam (penoplex):

Cured foam may contain some synthetic fillers, the presence of which determines the direction of application of the insulation - for walls, foundations, etc. The most common additives are flame retardants to increase fire safety (reduce the degree of flammability), antioxidants to protect the material from oxidation in the open air, antistatic substances to relieve static and dynamic stress during insulation operation, light stabilizers (protection from the negative effects of UV radiation), modifying additives and etc.

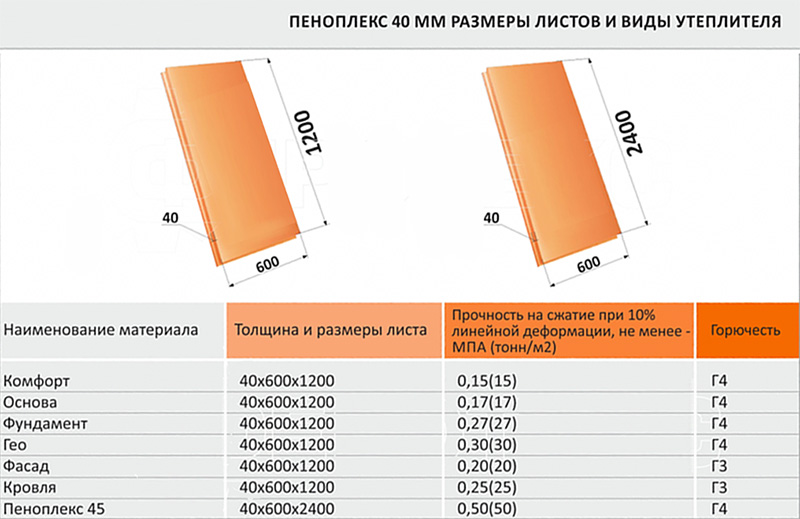

Polystyrene foam is pressed under pressure from the extruder chamber onto a conveyor for final formation into slabs or blocks. The percentage of gases in the insulation reaches 98% of the total volume of the finished penoplex, so the products are light in weight with impressive dimensions. Dimensions for each functional line of insulation are given in the tables below.

Small size pores (0.1-0.3 mm) and their complete isolation from each other guarantees high thermal insulation performance of any brand of penoplex. For different construction projects, it is necessary to select the appropriate series and brands of insulation, since structures can be operated under different conditions:

A separate category produces sandwich panels, which are an improved thermal insulator for insulating attics and attics, facades and foundations of buildings. The sandwich panel has 2-3 layers and cement bonded particle board as a bottom layer.

Advantages of penoplex:

Disadvantages of penoplex:

The “Wall” brand is a renamed Penoplex 31 insulation with fire retardant additives, which has been improved for use in insulating “wet” facades, building foundations, plinths and basements, partitions and walls of houses outside and inside, roofs and attic spaces. The characteristics of penoplex brand “Wall” are in the table below:

The “Foundation” brand is a renamed “Penoplex 35” insulation without fire retardant additives, which can now be used to create thermal insulation for the bases and plinths of buildings, blind areas and basements. The strength, waterproofness and thermal conductivity of the "series" are its main advantages. The characteristics of the “Foundation” are given in the table below:

Penoplex insulation of the “Roofing” series is a renamed material “Penoplex 35”, which is recommended for use in the insulation of pitched and flat roofs any design. The use of the “Roof” series makes the further operation of the roof as simplified as possible, since the reliability and long service life of the insulation minimize the possibility of repairing the roof surface. The popularity of this innovative insulating material is also due to the fact that greenhouses and summer gardens- such trends are now in fashion. Penoplex can withstand so much high loads, that he doesn’t care about a load of soil up to several tons. Characteristics of the foam insulation brand “Roof” are in the table below:

“Comfort” is a universal brand of heat insulator

“Comfort” is a universal brand of heat insulator Penoplex "Comfort" is a modified and improved "Penoplex 31C" with universal characteristics. The material is actively used for insulating country houses, country houses and cottages. The high speed of installation and minimal labor costs popularize the insulation among private homeowners - it is used to insulate the subfloor, foundation and basement of a house, basement and roof, walls and partitions from the inside and outside of the building. Penoplex "Comfort" has high levels of moisture resistance and thermal conductivity. In the penoplex series line, the Comfort brand is recognized as universal.

Penoplex protects the soil from heaving when it freezes - when the soil is insulated with this material, the freezing point of the soil will rise. This series is optimal for insulating road and railway surfaces, runways and technical areas of airfields. Comfort slabs retain their unique characteristics during the entire period of operation. Characteristics of the “Comfort” penoplex insulation brand are in the table below:

It is a misconception to think that penoplex and foam plastic are brother materials. Some properties of penoplex can be equated to the parameters of polystyrene foam, but not flammability and water absorption.

Manufacturers have long mastered the production of both non-flammable polystyrene foam and high-burning polystyrene foam. But the truth is that penoplex cannot spontaneously ignite, and in an open fire zone it will only melt, releasing carbon monoxide (CO) and carbon dioxide (CO 2) gases. If the fire is extinguished, the penoplex will not even smolder.

- This is an insulating material, usually white. It is made from thermally expanded polystyrene. In appearance, the foam is presented in the form of small moisture-resistant granules, during the melting process at high temperature melted into one whole slab. The sizes of the granule parts are considered to be from 5 to 15 mm. The outstanding thermal conductivity of 150 mm thick foam is achieved due to a unique structure - granules.

Each granule has a huge number of thin-walled micro-cells, which in turn increase the area of contact with air many times over. We can say with confidence that almost all foam plastic consists of atmospheric air, approximately 98%, in turn, this fact is their purpose - both outside and inside.

Everyone knows, even from physics courses, that atmospheric air is the main insulator of heat in all thermal insulation materials, is in a normal and rarefied state, in the thickness of the material. Heat-saving, the main quality of polystyrene foam.

As mentioned earlier, polystyrene foam is almost 100% air, and this in turn determines the high ability of polystyrene foam to retain heat. This is due to the fact that air has the lowest thermal conductivity. If we look at the numbers, we will see that the thermal conductivity of polystyrene foam is expressed in the range of values from 0.037 W/mK to 0.043 W/mK. This can be compared with the thermal conductivity of air - 0.027 W/mK.

While, such as wood (0.12 W/mK), red brick (0.7 W/mK), expanded clay (0.12 W/mK) and others used for construction, it is much higher.

Polystyrene foam provides a high level of energy saving due to its low thermal conductivity. For example, if you build a brick wall with a thickness of 201 cm or use wood material 45 cm thick, then for foam plastic the thickness will be only 12 cm for a certain amount of energy saving.

Therefore, the most effective material of the few for thermal insulation of external and interior walls buildings are considered to be polystyrene foam. Residential heating and cooling costs are significantly reduced through the use of polystyrene foam in construction.

Excellent qualities have found their application in other types of protection, for example: polystyrene foam, which also serves to protect underground and external communications from freezing, due to which their service life increases significantly. Polystyrene foam is also used in industrial equipment (refrigeration machines, refrigeration chambers) and in warehouses.

The production of polystyrene foam boards is carried out according to GOST standards. In the production of polystyrene foam, both the composition and dimensions of the sheets are regulated. The standard sheet length ranges from 100 cm to 200 cm. The width should be 100 cm, and the thickness should be from 2 cm to 5 cm. The thermal conductivity of 50 mm foam is relatively high, due to the small thickness and characteristics of the material, it is the most popular of all.

The building materials market offers a huge selection of polystyrene foam boards. The high thermal conductivity of insulation boards depends on their type. For example: a sheet of polystyrene foam PSB-S 15 has a density of up to 15 kg/m3 and is 2 cm thick. For a sheet from 2 to 50 cm, the density is no more than 35 kg/m3. When comparing polystyrene foam with other similar materials, you can easily trace the dependence of the thermal conductivity of polystyrene foam boards on its thickness.

So, for example: the thermal conductivity of polystyrene foam is 50 mm, twice that of mineral wool of the same volume; in this case, the thermal conductivity of polystyrene foam with a thickness of 150 mm will generally be 6 times higher than these indicators. Basalt wool, is also very inferior to polystyrene foam.

In order to apply one of the insulation methods, it is necessary to select the correct dimensions of the material. The following algorithm can be used to calculate:

If you are interested in the question of what is the best brand to buy polystyrene foam, and what is its thermal conductivity, then we will answer it for you. Below are the most popular product brands, as well as the density values and thermal conductivity of the foam.

Our list is completed by polystyrene foam PSB-S5, whose thermal conductivity is 0.04 W/mK and density is 35-50 kg/m3. Having analyzed the density and thermal conductivity, we can say with confidence that density does not significantly affect the main quality of the foam, heat saving.