If you have certain materials, you can make an incubator yourself. However, successful incubation of eggs depends on a number of factors, and in order not to spoil them at the very first laying, it is important to anticipate all possible issues in the operation of the manufactured structure. Let's consider one of the popular options for creating such a device.

In addition to incubators with “manual” or semi-automatic egg turning, there are automatic incubators that minimize human intervention in the process of hatching chicks. According to the time set by the owner, the automation itself performs the required revolution, and the eggs do not lie in one place.

Such machines can be built at home, but first of all, it is important to take into account all its possible advantages and cons.

In addition, if the components for the future device can be found at home, then you will get the finished incubator completely free of charge.

This group of characteristics mostly includes disadvantages associated with inaccurate calculations and the use of old materials.

Without knowledge technical specifications incubation, not a single assembled incubator can provide good productivity, therefore, before getting down to work, it is worth considering some requirements for automatic designs:

Important!To use a homemade breeding incubator different types For birds, it is useful to purchase a ready-made universal tray that ensures timely turning of their eggs.

If you are going to create an incubator yourself, then one of the good solutions is to use an old refrigerator. Of course, it will have to be completed and the consumables selected correctly.  To do this, you need to make sure that the finished structure:

To do this, you need to make sure that the finished structure:

However, all this will be calculated during the actual collection, and first you should correctly calculate the size of the device and select all consumables.

The dimensions of the finished homemade incubator will directly affect the number of eggs for one laying, so if it is important for you to get as many chicks as possible at a time, then we suggest focusing on the following approximate values:

Concerning external dimensions devices, they depend on the chosen material, because, for example, foam plastic will be more voluminous than cardboard. In addition, when manufacturing structures with several floors, completely different technologies will be used, which means that calculations will be made taking into account the parameters of each tier.

The size of the incubator will also be affected by:

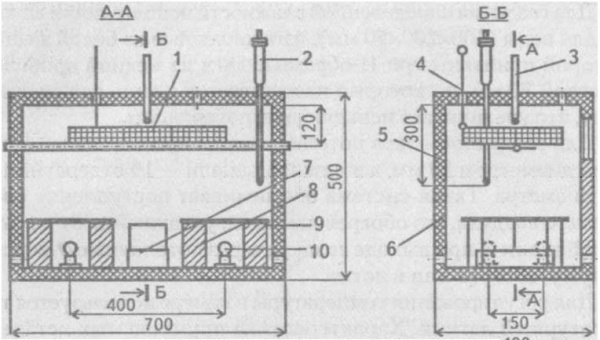

In order not to make mistakes in calculations when designing an incubator, it is important to adhere to a pre-designed diagram, which for a small device for 45 eggs can look like this:

The design of an incubator has much in common with the design of a refrigerator, which will make a good case: the walls refrigeration equipment They retain heat well, and you can use existing shelves as shelving.

Did you know? In Russia, the first mass production of incubators dates back to beginning of the 19th century centuries, and the volumes of such machines were very impressive: 16–24 thousand eggs could be placed in them at a time.

Main list necessary tools and materials will look like this:

How to make an incubator with automatic tray turning with your own hands: video

Approximate diagram of the finished product:

The entire process of making a home incubator from an old refrigerator will take only a few hours, as it consists of small quantity main stages:

Finally, you should check the functionality of all mechanisms by turning on the device for several hours.

Before being placed in an incubator, all eggs must lie in the room for at least 8 hours, because if they were previously in cool conditions, then when placed in a warm incubator, condensation cannot be ruled out.  No less important stage preparation is the culling of unsuitable eggs.

No less important stage preparation is the culling of unsuitable eggs.

So, the following specimens are not suitable for further incubation:

The next stage is direct placement into the incubator, which also has its own characteristics:

The duration of incubation of different types of poultry has significant differences, which means turning the eggs should be done differently.  In addition, the conditions for embryo development will also vary:

In addition, the conditions for embryo development will also vary:

Did you know?Chickens are excellent at remembering faces and are able to retain up to a hundred images in their memory, not only human ones, but also animals.

Suitable temperature is one of the most important conditions for incubation, without which hatching of chicks is simply impossible.

For each type of bird, these indicators are purely individual, so when laying eggs from chickens, ducks, geese or turkeys, you should focus on the following values:

In general, a homemade incubator - good decision both for those who are just trying themselves in poultry farming, and for experienced farmers who do not want to spend extra money on purchasing finished equipment. By equipping the structure with automatic egg turning, you can achieve 80–90% hatchability of chicks.

It turns out that anyone can hatch chicks poultry, you can do without not only the services of a hen hatching eggs, but also without an expensive factory-made incubator. For the home handyman It is quite possible to independently manufacture a device for incubating eggs, which allows you to successfully hatch chickens at minimum cost funds. Read below about how this can be done.

The main requirement that any incubator must fulfill is its ability to maintain conditions as close as possible to the natural ones created by the bird hatching its eggs.

Important! The distance between eggs loaded into the incubator must be at least 1 cm.

And from here follow all other requirements for incubators:

Polystyrene foam is perfect for this purpose. This material being cheap, it is light both in weight and in processing, and has an excellent ability to retain heat, which is an indispensable quality when incubating eggs.

To make a small incubator for 15 chicken eggs out of polystyrene foam, you will need:

To assemble a home incubator based on a ten-liter thermobox, you need:

Important!For better preservation To prevent heat inside the foam incubator, it is recommended to cover it with thermal insulation covered with foil from the inside.

The most popular way homemade The incubator is the use of the body of an old refrigerator, i.e. the unit, once aimed at producing exclusively cold, turns into its opposite, now producing the heat necessary for the incubation process.

Moreover, the incubator turns out to be so “advanced” that it even contains a device that turns the eggs automatically.

To make this device, you can use:

This DIY home incubator design requires an old refrigerator with a separate freezer.

Then you need to do the following steps:

This is the most difficult and important part of the construction of this type of incubator. The turning mechanism must reliably turn the eggs in a given mode, doing this not only in a timely manner, but also accurately.

To install it you need:

Video: mechanism for turning trays in an incubator from a refrigerator

In a market economy, each person is the master of his own wealth. Now anyone can lead decent life, because there are more than enough opportunities to earn money, for example, you can make an egg incubator yourself. This will allow you to create small farm, which will become a source of income in the future.

After you make an egg incubator with your own hands, you will have the opportunity not only to earn extra money, but also to provide for your own household. However, for this to become a reality, it is necessary to approach the creation of this device as responsibly as possible. After all, the success of the whole idea depends on how correctly it works.

The design of the egg incubator itself is not particularly complicated. If you have been breeding poultry for a long time, then you know that a chicken can hatch even under the light of a lamp. However, if you set the temperature too low, nothing will happen. Elevated temperature regime will also not lead to anything good.

Therefore, before making an incubator yourself, it won’t hurt to thoroughly study all the drawings, and most importantly, understand how the thermostat works. After which you just have to select the appropriate mode and load the tray.

Of course, you can just buy an egg incubator, but the price of a device for such a simple design is really too high. It is much more practical and cheaper to do everything yourself.

There are many different drawings of an egg incubator that you can bring to life with your own hands. However, in order for everything to go as expected and the device you have built to adequately perform its functions, the following conditions must be met:

Before making an incubator with your own hands, watch the video below. Despite its apparent primitiveness, the incubator works great and allows you to hatch chickens at home.

To make a truly high-quality incubator yourself, you need to approach this matter with maximum responsibility. First, study the drawings, do it without them good project It definitely won't work.

IN project documentation there should be information including a thermal control diagram. This should indicate where the heating elements are located. Then you can make your own incubator, which will serve you for many years, allowing you to hatch chickens.

You yourself will have to study the mechanism for rotating the structure; you need to choose one that will simultaneously ensure stable operation and at the same time be quite simple to manufacture.

Important ! When you create the structure yourself, consider the possibility of laying eggs in the cells different sizes. This will allow you to expand your household in the future at minimal cost.

The fact is that the market is very flexible. At one time, chicken meat may be popular, but tomorrow everyone will start asking for goose meat. The day after tomorrow there will be a fashion for quail eggs again.

You must include temperature control mechanisms in your drawing. The fan should be installed exactly where it will benefit the most. In addition, it doesn’t hurt to think about an alternative light source. Even a short period of time without heating can cause improper development of chicks.

Based on all of the above, when choosing a drawing of a future design or making it yourself, it is best to focus on the following parameters:

It is best to set the turning speed to one hour. This will allow you to achieve the greatest effect when operating the entire system.

In most cases, people who want to make an egg incubator with their own hands use a refrigerator as the initial preparation. The fact is that its design is ideal for this task. In addition, the financial costs with this option will be minimal.

So, if you're interested in how to make your own incubator at home, start by finding an old refrigerator. It is from this point that the implementation of this project will begin.

First of all, to make a high-quality and durable incubator yourself, get rid of the freezer. You will also need to get rid of all other built-in equipment. Fortunately, you can easily do all this yourself. To further implement the project, you will need a contactor-relay KR-6 and a thermometer with electrical contacts.

Attention ! The coil in the device must have a resistance that will limit the power to 1 W.

Once you select all these devices, you will be able to connect the power supply yourself without any difficulties. Power supply must be supplied from a network with a voltage of 220 V.

The first four lamps turn on first. Their task is to raise the temperature to 38 degrees. After this, you will need to close the contacts of the thermometer. As a result of this action, the KR coil will receive power. Additionally, contact KP2 opens. As soon as the temperature drops, the process is activated again.

As you can see, making a high-quality incubator yourself is quite simple. The main thing is to set the temperature correctly, take care of the turning system, and so on.

Uniform heating is provided by lamp L5. Moreover, it is needed to provide the necessary humidity. Moreover, its presence reduces the load on the relay contactor. So be sure to install it for her. Fortunately, you can easily do this yourself.

Attention ! After the air inside the incubator has heated to the required temperature, you will need to turn off 2 lamps. Without automation, you'll have to do it yourself.

The estimated power of the incubator that you need to make will be 40 W. This is if there is no ventilation and rotary mechanism. They can be excluded from the design for greater savings, but in order for the result to be satisfactory, care must first be taken to create natural circulation air inside. Hoods will help you with this.

If you want to abandon the rotating mechanism in the design of the incubator in which the eggs will be placed, you will have to rotate the cells yourself. This must be done at least 3-4 times and only daytime days. However, the rate of maturation with this approach will drop significantly.

Attention ! It is best to use ordinary trays as cells for eggs.

On the ninth day in the incubator you will need to lower the temperature yourself to 37.5 degrees Celsius, by 19 to 37. If you do not want to spend money on an uninterrupted power supply, then put several bottles with hot water. This should be more than enough to maintain the desired temperature.

The heating elements in an incubator that you make yourself can be placed not only above the tray, but also on the side, and even below it. Many experts agree that the best option will place the lamps around the entire perimeter yourself. This will ensure the most even heating.

Attention ! The distance between the bulbs cannot be less than 25 cm.

Some poultry farmers go to the tricks they buy nichrome wire. This is a fairly powerful heating element, which makes it possible to reduce the distance between heat sources to 10 cm.

There are three types of thermostats that ensure the correct temperature inside the incubator, which you will make from a former refrigerator with your own hands:

If you are thinking about how to make your own egg incubator, consider an automatic thermostat. Of course, its installation will take more time, and you still need money to buy it. However, this will ensure almost complete autonomy.

It is worth recognizing that it is advisable to heat quail eggs in special conditions. First, you need to use a water tank as a heating element in an incubator that you make yourself. It will provide sufficient heating.

The tank is best made of iron. The wall thickness will be about 4 mm. Don't forget to solder the seams carefully. The height of the upper pipes should be 30 mm. The diameter of the pipes is at least 4 mm. They are welded into the top cover.

And now the most important thing. 100-watt lamps are lowered into the resulting structure. The flasks must be immersed in liquid up to the cartridges. Moreover, it is necessary to make sure that the two heating elements duplicate each other in the incubator for quail eggs, which you make yourself.

As you can see, making an incubator yourself is more than possible. To do this, just find an old refrigerator and remove all the equipment from it. The average tray in the incubator is enough to hatch about a hundred chicks.

Of course, making an incubator for quail eggs will require a little more effort. But their price on the market fully justifies this step. The main thing is not to forget to include these costs in your business plan.

There is a great opportunity to save money - make an incubator yourself. It's not as difficult as it seems at first glance. From the article you will learn about the features of creating an incubator from available materials, what are the requirements for this process, and how to choose the right eggs for laying.

Incubators do various sizes according to the number of eggs that are used when laying. The location of the device also plays a role. But even the simplest incubator must be equipped with a thermometer to record the microclimate, ventilation, and egg trays.

Did you know? A day-old chick has the same skills and reflexes as a 3-year-old child.

For example, before you start assembling a device, you need to consider every little detail. It is possible to eliminate some shortcomings, since it is within the power of everyone who is going to create an incubator. Then you don’t have to think about purchasing a store-bought one.

In order for a structure to perform its assigned functions effectively, it must meet the following requirements:

Important! It is the complex of these three components that provides the eggs with the same conditions as under the wing of a hen.

Today, home incubators are made from the most various materials and devices (there are examples of similar devices made even from a microwave oven).

However, their manufacture must always comply with a number of general rules:

Did you know? U p A rooster has many functions in a chicken flock: it calls hens to food, protects them from small predators, and prevents conflict between birds.

Now in more detail about how to make homemade device for incubating chickens and other birds.

To assemble the device, you will need diagrams and drawings with dimensions, as well as a set of tools and various materials from which you plan to create an incubator.

If you don’t want to assemble a mechanism for automatic turning yourself (as described in the example above), then you can buy one already finished design: it is fixed in any homemade device.

The operating principle of the automatic turning mechanism is simple and effective. It not only performs the functions of a hen, but also allows you to maintain the temperature inside the device, because the lid is opened less often. Having such equipment, you do not have to worry about being able to turn the eggs in the device in a timely manner.

An equally popular option for a homemade incubator is making one from non-working refrigerators. For this, you can use both two-chamber and industrial devices, because their design provides for careful temperature preservation (which is extremely important for an incubator).

In addition to the refrigerator, to create the device you will need:

It is worth preparing a number of tools for work:

Assembling a device from a non-working refrigerator involves several steps:

Polystyrene foam (or polystyrene foam) is considered one of the most cost-effective and suitable quality materials for creating a home incubator. It holds heat well, is lightweight and easy to work with.

Did you know? The chick embryo needs oxygen already on the 6th day of incubation.

To make an incubator from penoplex, you will need the following materials:

Also prepare your tools:

Let's start assembling the device:

Important!Some amateur poultry farmers also install a fan in the incubator to better circulate air. Only the air flow from it should be directed towards the lamps, and not the eggs: this will dry them out.

Having assembled the incubator, you can begin selecting eggs for laying. Not all of them are suitable for poultry breeding.

Therefore, it is important to know how to choose the right ones:

Important!If you plan to place eggs in one bookmark various types(chickens, geese, ducks), then use trays at different levels for this. Each bird has its own requirements for timing and temperature, and it is important to adhere to them for a successful result.

But it is important not only to choose the right planting material, but also prepare them for bookmarking:

After laying the eggs, periodically check their quality. Already 6-7 days after the start of the process, it is worth shining them through a lamp: they should already be visible blood vessels in the protein and a dark embryo.

Temperature - the most important condition for hatching eggs. Lack of heat slows down the growth of embryos, and prolonged hypothermia leads to death. Overheating can lead to the same consequences. Even if the embryos survive, the chicks will end up with deformed body parts and organs.

Different bird species have their own parameters for a suitable microclimate:

Did you know?Chickens cluck for a reason: they constantly exchange information about what is happening around them, including their own well-being.

So, making an incubator with your own hands is not so difficult and expensive. But you can create a device that is ideal for your conditions in terms of size and number of eggs for incubation. Before assembly, carefully study the rules and sanitary standards regarding such devices, otherwise the success of the enterprise will be in doubt.

If you often raise chickens, you know that you cannot do this without a good incubator. Either the hen did not arrive in time, or a breed of chickens with poorly developed brooding instincts (most laying hens), or the absence of adult chickens altogether. In this case, of course, you need to buy an incubator. But you can do it yourself. Let's try to figure out how to make an incubator with your own hands.

This name will probably surprise many, at least. How can a refrigerator be an incubator? The answer is - maybe even so! But everything is in order. As for the homemade device, many of our domestic poultry farmers successfully raise chickens even in the simplest incubators. Such homemade apparatus can serve as a faithful assistant until the breeder acquires an automatic industrial production.

We also recommend that you familiarize yourself with incubators on aliexpress.

As materials and tools during work we will need:

So, if you have an old refrigerator, then don’t rush to throw it away. From its chamber it is easy to build a homemade incubator for home poultry farming. The fact is that the design of the refrigerator itself holds it well constant temperature inside, which is very convenient for our case. All you need is the former refrigerator itself, 100-watt light bulbs (about 4 pieces), a temperature controller, and a KR-6 contactor-relay. So let's get started.

For visual clarity, we suggest viewing a drawing of a homemade incubator.

Drawing of an incubator from a refrigerator

A refrigerator incubator with automatic egg turning is very convenient and completely replaces a conventional industrial production device. However, in order to do it you will have to work a little. But as a result, depending on the brand of refrigerator, you will be able to warm up about 50 eggs at a time without any problems.

Diagram of the device of S. Kozin’s homemade incubator: 1-temperature regulator sensor; 2-thermostat; 3-incandescent lamps; 4-fan; 5-knob for rotating trays; 6-trays; 7-plate; 8-bath with water.

For example, P. Yakimenko from Moscow offers us one simple design. He made a homemade incubator out of ordinary cardboard box size 56x47x58 cm. The inside of the cardboard is covered with paper or felt in two layers. A 12x10 cm viewing window is made in the upper wall. Small holes are also provided for wires. With their help, three 25 W light bulbs are installed inside.

Lamps for heat transfer should be installed at a height of 15 centimeters from the surface of the eggs themselves. It is important to seal the holes where the wiring is inserted with cotton wool to prevent heat leakage. Then they make wooden trays, a convenient door, and slats for the trays.

In such a simple homemade device, it is also important to maintain high temperature, so we attach a thermometer to a special bar. For high humidity Place a container of water inside the device. In the first 12 hours after laying the eggs, the temperature in the box should be approximately 41 degrees, in the subsequent hours it is reduced to 39 degrees.

It is important to install such a device yourself not on the floor, but not on small bars 15-20 centimeters high. There must be constant air circulation, both inside and outside the box.