What requirements does GOST 8020-90 contain for well rings? What types and sizes are these products? How much do they cost?

We will answer these and many other questions in the article.

GOST 8020-90 regulates the production of all structures made of heavy (that is, not porous in any way) concrete with and without reinforcement, used for the construction of round wells for the following purposes:

It is curious: the standard does not provide for the use of structures for centralized heating inputs, the construction of water intake wells, septic tanks and cesspools.

However, in practice, such versatile products, of course, are used much more widely than the normative document provides.

Let's go over the most interesting points of the standard.

What is the diameter of the rings? The diameter of the well ring varies from 60 to 250 centimeters.

In the photo - KS-25-12. Diameter - 2.5 meters.

Let's clarify: we are talking about the inside diameter. The outer one is 16-24 centimeters larger due to the thickness of the walls.

The minimum height of the well ring is only 150 millimeters (for example, for KS-7-1.5). Maximum - 3.5 meters (KS-7-3). However, products with a height of 90 - 100 centimeters are in the greatest demand.

What is the volume of water in the well ring? The volume of a cylinder is equal to the product of the square of its radius times its height times pi. Thus, for the most running rings with an inner diameter of 1.5 meters and a height of 0.9 meters, the internal volume will be (0.75 ^ 2) x 0.9 x 3.1415 \u003d 1.6 cubic meters.

To get the volume of the well ring in liters, it is enough to multiply this value by 1000: 1.6 x 1000 \u003d 1600 liters.

The formula for calculating the volume of a cylinder. R is its radius, H is its height.

Do these products always represent an ordinary thick-walled cylinder? Not at all.

In the price lists of manufacturers, you can find the following varieties of them:

Note!

Bottom rings are often used for the construction of cesspools and primary clarifiers in makeshift septic tanks.

However, for these purposes, it is much better to use plastic containers or, in extreme cases, monolithic concrete structures.

The instruction is connected with the inevitable violation of the tightness of the seams over time and, as a result, the contamination of the soil with untreated effluents.

Note: when choosing reinforced concrete products it is worth considering that sellers (not manufacturers, namely sellers) do not always orient themselves in the marking or distort it.

For example, a well ring K 10 by 10 may well turn out to be both a KS-10-10 ring and a KCD-10-10ch ring in the real world, which differs from the previous one in the presence of a bottom, a lock and a twofold difference in cost.

How much does a well ring cost? Of course, the price depends on its size and shape.

Here are a few examples from the price list found on the open spaces of the worldwide network.

For many types of communications, not only pipes are often used, but also reinforced concrete rings. Today we will be interested in those types that are used for the device autonomous sewerage. Previously, when the rings were inaccessible to an ordinary developer, the sewer well was either poured with concrete along the formwork or laid out with bricks. Naturally, this took a lot of time, money and cost a lot of effort. Sewer rings have become available and with their help it is possible to complete a turnkey septic tank, down to the very last element, including the manhole cover.

Does it make sense to buy sewer rings, is determined in each case, based on the parameters of the future septic tank. But in order to roughly estimate the estimate, you can look at the table, which shows the prices for different reinforced concrete sewer rings.

Naturally, to choose, you need to know the size of the ring, and for this you need to carry out a simple calculation. First of all, you need to know how many people permanently live in the house and multiply the number of residents by the daily rate of water consumption. This is an average of 200 liters. It is also believed that in three days a completely filled septic tank processes all sewage. Therefore, multiplying all these data, we get the volume of one ring in cubic centimeters. We divide by 100, as a result we get the required volume in cubic meters. The internal volume of the ring is calculated by a simple formula:

Substituting the data obtained into this formula, we obtain the required diameter of the ring. Now, using the size table below, we select the most suitable option among standardized sizes concrete rings.

By design, sewer rings can be of three types:

These are the main types of rings, but there are also products of a smaller height. These can be adjusting rings and additional elements that allow you to bring the height of the well to the required level relative to the ground. There are also rings with a larger wall thickness and a smaller diameter, which allows you to adjust the volume of the well. The additional element completely repeats the inner diameter of the main ring and allows you to set the inspection hatch at the required level.

Sewer rings are extremely durable and cheaper than similar products for drinking water. The fact is that when choosing elements for the device of the well, it is necessary to be interested in what kind of solution was used to coat the mold during casting. For the manufacture of well rings for water, a wax-based coating is usually used, it is more expensive, but such rings will not leave marks and stains on the water. Other benefits of sewer rings include:

There are also some disadvantages. First of all, they have a lot of weight. By the way, there is no need to calculate the weight for each ring, typical dimensions and the weight corresponding to them are given in a separate table. Difficult transportation and installation using lifting mechanisms also complicate the process of building sewer shafts, and in addition, for the operation of heavy equipment, it is sometimes necessary to sacrifice a certain area of the fertile soil layer.

The process of mounting the rings is only partially mechanized, so the main work has to be done manually. If the shaft were square or smaller in diameter, it could be dug by drilling or using an excavator, and since the well has round shape, you have to dig manually. Initially, a pit is pulled out, exceeding the dimensions of the first concrete ring by 10-15 cm, after which a ring is installed there, which will be the lowest.

Next, the soil is progressively removed from the well, the first ring is lowered, and the next one is installed in its place, and so on until the desired depth is reached. The joints are treated with concrete coating, and either a special round one is laid on the bottom of the well concrete slab or the bottom is simply concreted. The upper ring is coated with clay, a floor slab with a hole for the hatch is laid on top, either a cast-iron or plastic cover hatch, or covered with a concrete removable cover. Good luck to everyone and easy installation!

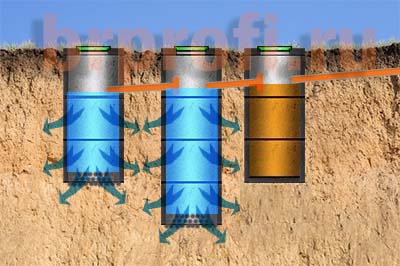

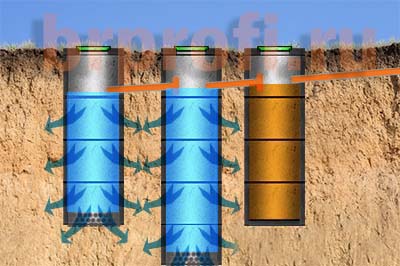

A septic tank made of reinforced concrete rings consists of several wells in which the rings are stacked on top of each other. The first well is a septic tank and is required to be installed, the remaining tanks (their number may vary) are a system of filter wells into which treated wastewater will be overflowed from the septic tank.

The volume of a septic tank is a value that cannot be taken from the ceiling or on the advice of neighbors. The calculation of a septic tank made of concrete rings is regulated by building codes, it is individual for each user and depends on a number of factors: not only on the number of residents living in the house, but also on the way of life, the degree of improvement of the building, soil composition, groundwater level, climate zone. Let's look at everything in order.

In our calculations, we will rely on such official documents as:

Code of Practice 32.13330.2012 dryly and tersely tells us the following (clause 9.2.13.3):

ECHZh - the equivalent number of inhabitants (in our case, the number of residents in the house).

If less than 25 people live in your house, then you can calculate the volume of a septic tank from concrete rings using the formula: daily water consumption by one person, multiplied by the number of people and by THREE days.

As we can see, paragraph 9.2.13.4 allows us to use a single-chamber septic tank, implying that after "preliminary cleaning" our septic tank will be pumped out. Our goal is the operation of treatment facilities without pumping, i.e. complete autonomy. Therefore, it makes sense to use two chambers (chamber 1 - a septic tank with a concrete bottom, chamber 2 - a filter well) or even three chambers (chamber 1 - a septic tank with a concrete bottom, chambers 2 and 3 - filter wells), despite the fact that SNiP recommends doing this, with a larger number of residents.

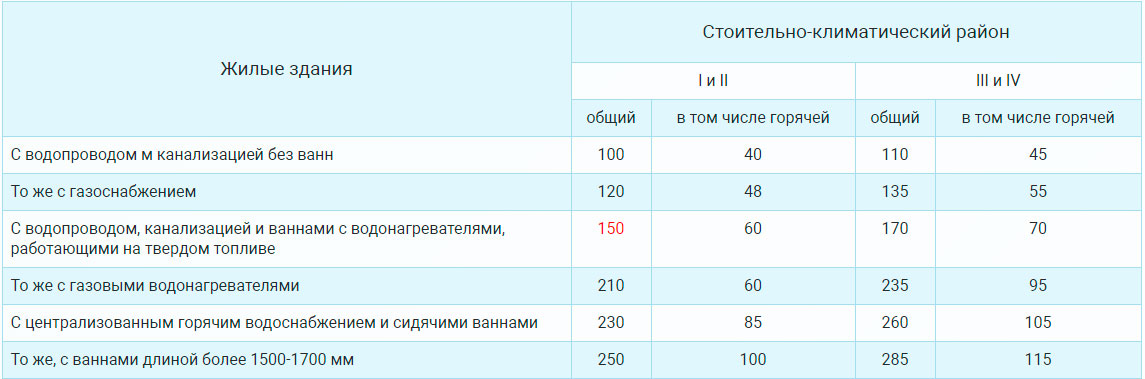

Water consumption per person is determined according to the Code of Rules 30.13330.2012 "Internal water supply and sewerage of buildings":

Table A.2 - Estimated (specific) annual average daily consumption of water (sewage) in residential buildings, l / day, per 1 inhabitant

| residential buildings | Construction and climatic region | |||

| I and II | III and IV | |||

| general | including hot | general | including hot | |

| With plumbing and sewerage without bathtubs | 100 | 40 | 110 | 45 |

| Same with gas supply. | 120 | 48 | 135 | 55 |

| With plumbing, sewerage and baths with solid fuel water heaters | 150 | 60 | 170 | 70 |

| Same with gas water heaters. | 210 | 60 | 235 | 95 |

| With centralized hot water supply and sitz baths | 230 | 85 | 260 | 105 |

| The same, with bathtubs longer than 1500-1700 mm | 250 | 100 | 285 | 115 |

For most country houses Moscow region (II climatic region), this figure will be at the level of 150 liters per day per person. With economical spending, the spillway can be reduced to 100 liters per day (possibly less). If you pour to the fullest, get ready to drain 250 liters of water per day per person.

The climatic region is determined according to SP.131.13330.2012 "Construction climatology". The average monthly temperature in January in Moscow is -7.8 ˚С, in July 18.7 ˚С. Based on this, we define the climatic zone as IIG (DVA-GE). You can read more about this on the page in the information section.

For example, imagine that 3 people live in our house.

The volume of the septic tank this case will be:

The calculator for calculating a septic tank from concrete rings provides fairly accurate data on the number of rings to be laid. Here it is worth considering that the volume of one ring KS-10-9 (Wall ring: inner diameter - 1 meter, wall height - 90 cm) is 3.14 * 0.5 * 0.5 * 0.9 = 0.7 m3 , or 700 liters.

This means that for the manufacture of a septic tank, we need:

At the same time, the upper ring is never filled purely technologically and remains dry. This is due to the fact that the inlet pipe (coming from the house) cuts into the septic tank at a depth of about 70 cm.

So, we need to add one more to our number of rings:

This will be your septic tank (the first well shaft), in which the wastewater treatment process is underway. Now, the treated effluents need to be drained somewhere ..

For this, another shaft (filtering well) is being built nearby, into which the treated wastewater will be overflowed from the septic tank. The main requirement for the second tank is that it must have time to give into the soil all the water entering it and all the drained water (and we considered its consumption above) must be absorbed into the ground! Only in this situation we will not have to pump out our septic tank and we will achieve full autonomy.

![]()

IMPORTANT! If in your area high level groundwater, then the filter well is not for you, but for your case you need to use aeration fields.

The filter well passes water into the soil through the bottom, as well as through holes in the walls of the rings. If the filtering well is not arranged correctly, the water will not have time to go into the ground and, as a result, it will have to be pumped out regularly, therefore, if one well does not cope with its tasks, then a second one is built nearby (more than 4 rings are not allowed in the mine) .

Or by doing a simple experiment:

Remove upper layer soil (chernozem) and having reached the bottom layer of soil, roll a ball out of it that fits in the palm of your hand:

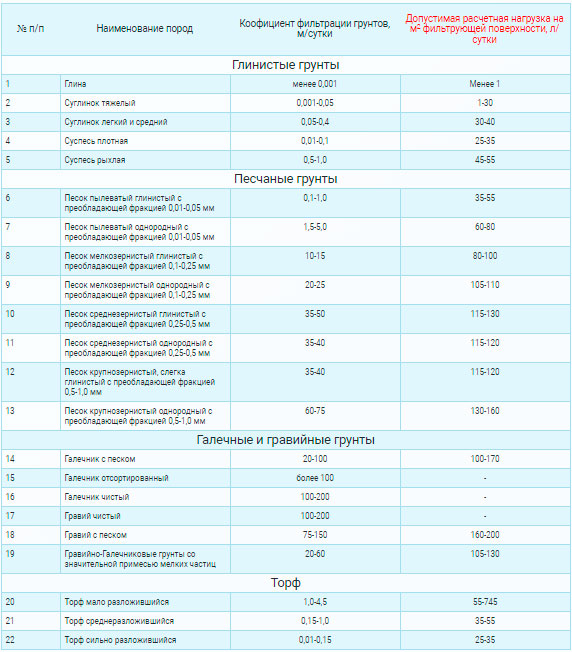

Having learned the type of our soil, we turn to the table "soil absorption forces" (STO NOSTROY 2.17.176-2015 pp. 25-26):

| No. p / p | Name of breeds | Soil filtration coefficient, m/day | Permissible design load per m2 of filter surface, l/day |

| Clay soils | |||

| 1 | Clay | less than 0.001 | Less than 1 |

| 2 | loam heavy | 0,001-0,05 | 1-30 |

| 3 | Loam light and medium | 0,05-0,4 | 30-40 |

| 4 | The slurry is dense | 0,01-0,1 | 25-35 |

| 5 | Loose slurry | 0,5-1,0 | 45-55 |

| sandy soils | |||

| 6 | Silty clayey sand with a predominant fraction of 0.01-0.05 mm | 0,1-1,0 | 35-55 |

| 7 | Homogeneous silty sand with a predominant fraction of 0.01-0.05 mm | 1,5-5,0 | 60-80 |

| 8 | Fine-grained clayey sand with a predominant fraction of 0.1-0.25 mm | 10-15 | 80-100 |

| 9 | Homogeneous fine-grained sand with a predominant fraction of 0.1-0.25 mm | 20-25 | 105-110 |

| 10 | Medium-grained clayey sand with a predominant fraction of 0.25-0.5 mm | 35-50 | 115-130 |

| 11 | Sand medium-grained homogeneous with a predominant fraction of 0.25-0.5 mm | 35-40 | 115-120 |

| 12 | The sand is coarse-grained, slightly clayey with a predominant fraction of 0.5-1.0 mm | 35-40 | 115-120 |

| 13 | Homogeneous coarse-grained sand with a predominant fraction of 0.5-1.0 mm | 60-75 | 130-160 |

| Pebble and gravel soils | |||

| 14 | Pebble with sand | 20-100 | 100-170 |

| 15 | Gravel sorted | over 100 | - |

| 16 | Pebble clean | 100-200 | - |

| 17 | gravel clean | 100-200 | - |

| 18 | gravel with sand | 75-150 | 160-200 |

| 19 | Gravel-pebble soils with a significant admixture of small particles | 20-60 | 105-130 |

| Peat | |||

| 20 | Peat, slightly decomposed | 1,0-4,5 | 55-745 |

| 21 | Peat medium decomposed | 0,15-1,0 | 35-55 |

| 22 | Peat heavily decomposed | 0,01-0,15 | 25-35 |

We select the type of our soil and, in the column on the far right, determine the amount of “water absorption” in liters per 1 m2 of the soil surface per day. In my case, these are loams and 35 liters per m2 per day. Therefore, in order to absorb all the water, we need to distribute it on the following surface of our soil:

The filtering well passes water into the soil through the bottom (on which a bottom filter is arranged from a layer of crushed stone ~ 20 cm), as well as through holes in the walls of the rings. In order to get the required amount square meters surface "absorption" we calculate the number of rings required.

So the bottom ring gives us 3.2 m2 of “absorption” surface, each subsequent ring adds another 2.5 m2, therefore, the number of rings we need:

We also take into account that this is the number of working rings, there will be another ring on top, as in the case of a septic tank. We get 4, 6 and 8 rings, respectively, for the constructed filter well.

We remember the rule according to which the maximum working depth of a septic tank is 2.5 meters. So in the second and third options, the filter well must be divided into TWO wells. In the case of an average flow rate, we get 2 shafts of 3 and 4 rings. In the case of maximum flow, we have 2 shafts of 4 and 5 rings.

Well, here are our results:

Given: 3 people, economical consumption, loamy soil, low groundwater level.

Result: treatment facilities from a 3-ring septic tank and a 4-ring filter well.

The cost of installation is approximately ~ 44,500 rubles.

Given: 3 people, average consumption, loamy soil, low groundwater level.

Result: treatment facilities from a septic tank for 3 rings and two filter wells for 4 and 3 rings.

The cost of installation is approximately ~ 65,000 rubles.

Given: 3 people, maximum consumption, loamy soil, low GWL.

Result: treatment facilities from a septic tank for 4 rings and two filter wells for 5 and 4 rings.

The cost of installation is approximately ~ 78,500 rubles.

The calculation of a septic tank for a private house is not so complicated, but in any case it is individual for EVERY SPECIFIC CASE. Only individual and correct calculation will give you that cleaning system that will work and not require frequent cleaning.