Stairs with winder steps 180 degrees are done in many homes today. They are great for making the most of limited space to connect parts of the structure. Winder steps are made when it is impossible to make a platform between marches on the turns. This design is safe and convenient to use.

When it is impossible to make a single-flight structure in the house, choose a staircase with a 180-degree turn. To make it with your own hands, metal is required, you can make it from wood. The complexity of the installation of stairs depends on the material.

It is better to use wood, because it may happen that the winder steps will have to be adjusted. If you choose steel or stone, then you will not be able to correct deviations in the dimensions of the parts. By choosing wood, you will eliminate installation inaccuracies, do this at any time when you begin to mount the structure.

Today, manufacturers offer blanks from which you can make parts wooden stairs. With their help, you will facilitate the construction process. Of course, you still have to adjust all the elements to size, but installation will be faster.

Carefully choose blanks in the store, because they are not always made from high-quality wood.

You can make the main details yourself, but you need to choose the right material. Buy accessories, you can easily find all the elements in stores. For example, decorative balusters are on sale. It is better not to make them yourself, because the manufacture of such elements will take time.

Timber is needed for stairs with turning steps. An array of beech or oak is perfect, but these are expensive breeds. If you want to save money, it is better to buy larch. Pine or maple is perfect. The wood must be dried, otherwise the bowstring will lose its shape, the steps will creak, and repairs will need to be made.

Buy suitable boards for mounting, choose lumber with a width of at least 55 mm. Purchase wooden blocks, fit products with a width of 40 mm. Additionally, you will need screws, screws or self-tapping screws. Don't forget about metal corners and quality construction adhesive.

It is worth noting that metal stairs rarely done with a turn. The thing is that their installation is very complicated.

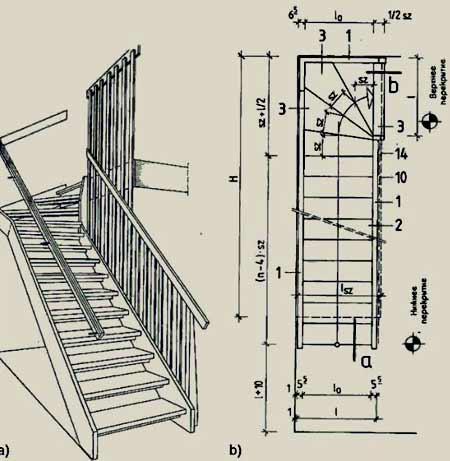

The supporting structure, also called the kosour, is required for the construction of stairs. Prepare from 4 to 6 stringers, their number depends on what angle of rotation the stairs will have, how many marches there will be in it.

Choose a support minimum cross section should be 100 by 100 mm. If we talk about the height of the pillar, then it depends on the turning staircase itself.

Calculate stairs. To do this, calculate the width of the march, determine suitable sizes steps. In addition, you need to think about what the turning radius will be. Measure the distance from the top of the angle of rotation to the last step, so you know the length of the projection.

Decide how wide you want the steps to be. Remember that on the same march they must be the same width.

It is difficult for one person to do the installation, since such a ladder weighs a lot.

It is better to invite an assistant, work together.

A design with 1 turn will have 2 flights that have different lengths. Make 8 steps in a long march, finish the top one at the beginning of the platform of the next floor. A short march of 3 steps, there will be 2 winders, but they are turned 30 degrees.

Video about installing stairs with a 180 degree turn:

When you mount the structure, install the railing.

The winder staircase drawing is in great demand in homes where comfortable, safe movement between floors is required, but there is no technical possibility of placing a direct structure. Such facilities require special attention at the stage.

Scheme with element names winder stairs

Winder steps are widely used for the following types stairs:

The shape of the turning tread for such structures has the shape of a truncated triangle. Due to the compactness of the device is saved.  Scheme of the device for turning the winder ladder

Scheme of the device for turning the winder ladder

Winder steps can be located at the bottom, top, in the middle flight of stairs. For safe movement, the first two options are recommended. They have good visibility of the turning area, which allows you to orient yourself in time and change the position of the foot or step length.

Winder staircases are more difficult to implement than straight structures or with transition platforms. Therefore, drawings with incorrectly executed structures are often found.

And this not only reduces the comfort of movement, but also increases the risk of injury from a fall.

Comfort and safety are the basic principles that any building structures. The staircase is no exception. A number of presented technical requirements, are also characteristic for direct mid-flight structures:  Scheme of a wooden staircase with winder steps

Scheme of a wooden staircase with winder steps

All of the above characteristics and data will ensure the comfort and safety of movement between floors.

The main advantages of winder stairs include:

Read also

Programs for drafting stairs in a private house

The disadvantages include a decrease in the level of comfort and safety of movement. Running treads differ in size, you will have to adapt. Yes, and disperse on such a march is more difficult than on ordinary stairs.  Classic winder look

Classic winder look

For the competent drawing up of a winding staircase scheme, it is required to take into account all the above standards, the dimensions of the premises and link them on the plan. To do this, proceed to the following steps:

Scheme and drawing of winder staircase These data will help to make correct selection design that will ensure compliance with building codes.

Scheme and drawing of winder staircase These data will help to make correct selection design that will ensure compliance with building codes.

Knowing the height between the levels and the formula for comfortable movement, you can calculate the length of the flight of stairs, the number of expected steps. For example, the specified height between floors is 2600 mm. We choose the height of the degrees from the recommended range of 120 mm. Let's make all the calculations to build a drawing:

The example shows that it is better to revise the parameters of the steps. This will save a lot of space. For example, with a riser height of 150 mm, the tread depth will be 300 mm, and the length of the stairs will be 5,400. Which will save 3 square meters. m. usable area at home.

Taking into account modern realities and get a quick result, you can use several ways to draw up a design diagram.

The best option for design. There are softwares that, based on the drawing, issue a specification for sawn materials. This option is not provided. But after completing a detailed drawing, it will not be difficult to calculate the amount of material. The disadvantage of this method is the time spent on searching and mastering the software product.

If an L-shaped staircase is installed in the room, then a situation is possible when, in order to reduce the size of the stairwell and save space, it is necessary to abandon the site and instead make winder steps.

A tread staircase is more compact than a landing design. However, winder stairs have a number of disadvantages, the most important of which are radial steps. irregular shape and the resulting features.

In this article, we will tell you how to properly design a staircase with winder steps so that it is convenient and safe to use.

To smooth out design flaws, corner stairs must be correctly designed by calculating winder steps, taking into account the following requirements:

After the main dimensions of the curved staircase are determined based on the video, it is necessary to calculate the configuration and number of winder steps.

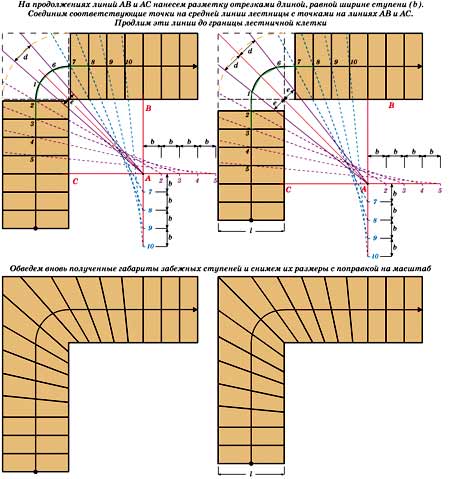

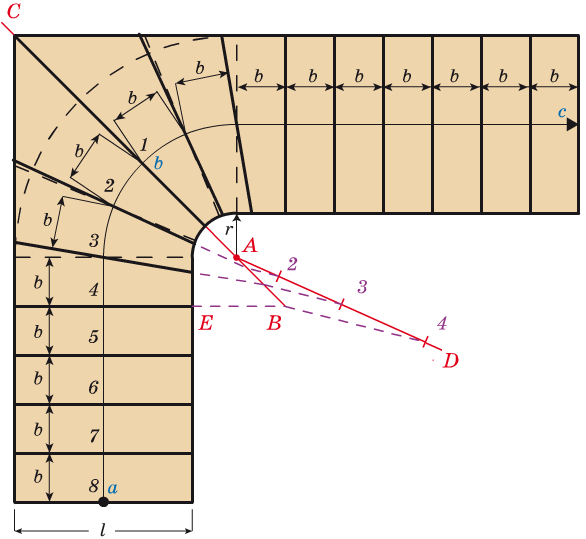

First of all, it is necessary to designate the center of the arc coinciding with the inner radius of the stairs, that is, point "A". Then determine the number of turning steps: the more of them, the less angle turn falls on each and the more comfortable it will be to move up the stairs.

Let's assume that the rungs will be steps up to the seventh inclusive. Then a straight line DE is drawn through the beginning of the eighth step. Line AB divides the staircase into left and right parts. In the middle of the march it is necessary to draw a curve ace corresponding to the line of motion. From AB on the line of motion, a section equal to ½ b, where b- the width of the usual step. We get point 1. Further from it we set aside a segment equal to b and mark point 2. Similarly, at regular intervals, mark the remaining points 3-7.

Further, through point 1 and A, we draw a straight line until it intersects with DE. We also draw a straight line through points 2 and A. On the DE section, we get points 1 and 2. We set aside segments equal to sections 1-2 on the DE line and mark them with numbers 3, 4, 5, 6 and 7, respectively. Now connect point 3 on the line of motion ace with point 3 on the line DE, then we connect the corresponding points 4, 5, 6, 7. Thus, the configuration of the steps is determined. A similar calculation is made for the right side of the stairs with turning steps.

As in the case of the U-shaped staircase, point "A" is located and a straight line AC is drawn. There are two options for the location of the steps:

In the second case, similarly to the U-shaped staircase, a line of motion is drawn ace. On a curved section, segments with a length of b(width of a straight step). The number of running steps is determined. Suppose these will be steps 1, 2, 3 and 4. Then a line EB is drawn through the end of step 4, where "B" is the intersection of lines EB and CA. Further, from the point “A”, segment AD is arbitrarily laid aside, and points 2, 3 and 4 are marked on it so that segment A2 is equal to two parts, segment 23 - three, 34 - four. An arbitrary segment equal to 1 conventional unit (cm, dm) is taken as one part.

Now we connect points 4 and B. From points 2 and 3 to the intersection with AB we draw straight lines, parallel to the segment AT 4. The points obtained in the section AB are connected, respectively, with points 3 and 2 on the line of motion ac. These lines define the winder configuration.

In the case when the straight line AC divides the step in half, the calculation of the winder stairs is carried out in a similar way.

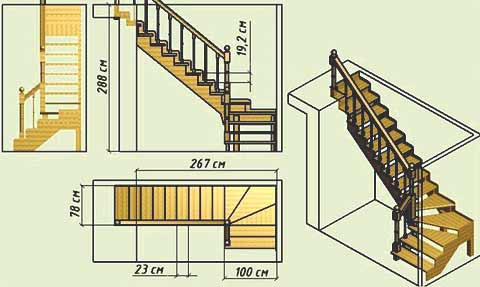

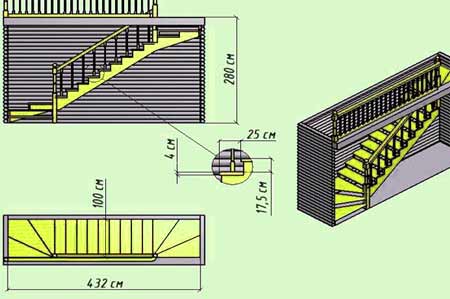

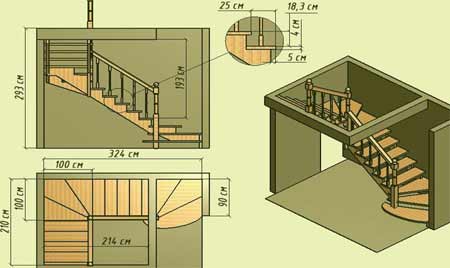

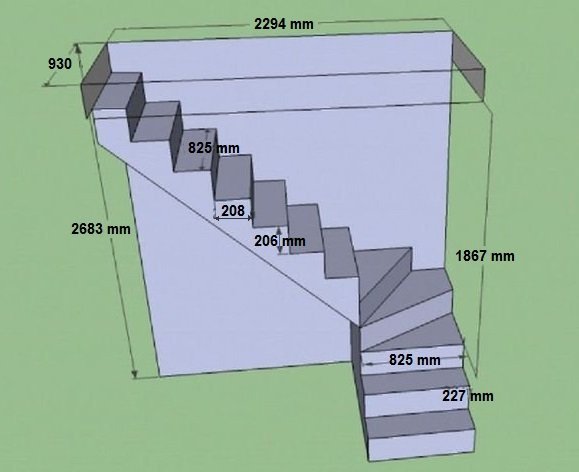

We will show how to make a winder ladder using the example of a structure with the following parameters:

The corner staircase consists of two marches. There are 8 steps in a long march, and the top one coincides with the platform of the second floor. There are 2 steps in the lower march. And three winder steps, the angle of rotation of which is 30 °. The project of a wooden staircase will look like this:

A wooden staircase with a turn is carried out on two stringers with dimensions of 50x300x3000 mm, one of which is fixed to the wall, and the other to support post with dimensions 100x100x2500 mm. It is also necessary to purchase steps 900x300x40 mm in size, a turntable 900x900x40 mm, from which winder steps will be cut, and balusters.

A wooden staircase with winder steps, having this shape and parameters, is made in several stages.

First you need to prepare a template, which is right triangle, whose legs are equal to the depth of the tread and the height of the riser. For convenience, the triangle should be fixed on the guide rail, as in the photo. Using this template, we mark the kosour and cut out the excess circular saw. It must be remembered that in the thinnest part, the width of the stringer should not be less than 15 cm.

In the corner we build an impromptu supporting structure, which will burst the wall stringer and serve as the basis for the winder steps.

We fix the upper ends of the stringers with metal corners.

After load-bearing elements will be fixed, it should look like this:

When installing stringers, it is important to monitor the level so that later the steps lie strictly horizontally. The most common mistake of inexperienced craftsmen is that horizontality is taken to be parallel to the floor. But the floor may be uneven, so this parameter must be determined only with the help of a level.

Winder steps are cut from a rectangular board 900x900x40 mm. For stairs with a 90 degree turn, three steps will suffice. To make them, we divide the board into three parts with lines coming out of one corner. The cut steps are adjusted in length.

Having decided which varnish to cover the stairs, we apply at least 3 layers on the steps.

To fix the winder steps, grooves are cut out in the column, the height of which is slightly less than the thickness of the board. So we will ensure reliable fixation of the steps on the inside of the stairs. A with outside- we are finalizing the supporting structure so that steps can be placed on it.

From the outside of the flight of stairs, the turning steps are screwed to the supporting frame using self-tapping screws. The inner ends of the steps are inserted into the cuts and glued with PVA glue mixed with sawdust to reinforce the structure.

We cut the end of the bowstring at a right angle relative to the floor so that the entrance pole can be installed.

Now you need to install balusters. Sometimes they are attached from below through the steps with self-tapping screws, but this method is unreliable. It is better to use dowels - cylindrical wooden rods.

To do this, a hole is drilled in the steps, the diameter of which is slightly smaller than the dowel section, and filled with glue. A similar hole is made in the balusters, and it is very important that it be exactly in the center. If the baluster has rectangular shape, then the center is defined as the intersection of the diagonals of the rectangle. Try to drill holes as accurately as possible so that they turn out to be strictly vertical, because the position of the balusters will depend on this.

A rope is stretched between the first and last pillar, along which the angle of inclination of the railing is marked on all balusters. Further, according to the applied marks, the tops of the racks are cut off. Thus, we prepare the balusters for the installation of the handrail.

The handrail can be fixed with simple self-tapping screws (solid), and the attachment points can be hidden with putty.

A single-flight staircase with winder steps is ready. Here's what we got.

With this manufacturing method, the load on the lower turning stage will act along the grain of the wood, which is undesirable as it weakens the structure. In this case, it will be necessary to additionally strengthen the step with a support, which we did.