The facade of the house is its face, which determines appearance buildings and even streets in general. That is why builders try to build structures from materials that look presentable in themselves: brick, natural wood or timber. But sometimes the facade needs to be finished using modern ways lining. We will tell in this article about decorating the facade of a house with our own hands using modern techniques, how to choose a material, what to look for, etc.

Do-it-yourself exterior decoration of a house is not as difficult as it seems at first glance. It seems that such work on the outside of the house is carried out only in order to make the appearance of the building more attractive. However, not only the aesthetic side of the issue matters here, there is also a practical benefit:

The owner of the house, together with the builders helping him, at the design stage of the house, needs to determine exactly which of the facade processing options to give preference to. This takes into account the method of heating the house (oven, boiler or a combination of types), and the area of \u200b\u200bthe facade, and what the walls will be made of. The fact is that after construction it will not always be possible to mount one or another sample, for example, materials for exterior finish houses may be too heavy and will not float on the surface.

Finishing the house outside is of the following types.

Plaster. This type of finish is suitable for stone houses with smooth walls, but for buildings made of natural materials, such as wood, plaster is hardly suitable. The advantages of plaster are obvious: it is both durability (up to 25 years, subject to all application rules), and hygroscopicity (it allows humid air from inside the room to pass through). This material contributes to the good preservation of wall materials and the preservation of the usual level of humidity. Exterior finishing of the house with plaster is often done for painting, to eliminate some irregularities. But plaster itself can become interesting option exterior decoration of the house. This method of processing external walls also has disadvantages: difficulties in carrying out work (there is no possibility of automating the process).

Stucco finish

Stucco finish Siding. This is a modern and affordable way to decorate a house from the outside with ready-made plastic panels that have adhesion to each other and details matched in color and material: wall siding, plinth, corner, etc. One of the advantages of siding is a large selection of materials for its manufacture: vinyl (PVC), metal (copper, steel, aluminum), wood, cement, etc. PVC panels are the most popular at the moment in building decoration. They are easy to connect, wash, they are durable and give the structure completeness. True, due to their excessive evenness and rigor, PVC siding panels have earned themselves the fame of materials that are similar to those that are processed office buildings.

siding finish

siding finish Facing brick. Fashionable, currently extremely popular material, among its main advantages is that it is the undisputed leader in offering a variety of textured surfaces, colors and their combinations. Brick for cladding is made of clay, and in itself is able to perfectly insulate the structure from the outside. In addition, it is easy to mount, it is only important to decide on the pattern in advance. This is an option that has practically no drawbacks, except that it is difficult for an inexperienced builder to choose an adhesive for it, which will ensure reliable adhesion of the wall and the surface of the brick.

Natural stone. The material is heavy, not on any surface, it will hold for a long time without problems. In addition, the disadvantages of natural stone there are such: it is very expensive and difficult to transport. Often used for finishing the basement. Positive traits for a stone, it is its naturalness, texture, color and status.

Artificial stone for decoration

Artificial stone for decoration Fake diamond. It combines the advantages of natural stone, but it is much lighter in weight, easier to process and has better adhesion to the surface. Disadvantages: difficulty in selecting the adhesive base, the need for a specialist for installation work.

Stoneware and tiles. These are the usual cladding options, and there is a huge selection of colors that can be found for every taste. The disadvantage of these materials is their high cost and the need to involve a specialist for its installation. Also, not every foundation can withstand the weight that appears during the installation of these materials.

When choosing a material for finishing the facade of a house, one should take into account the aesthetic needs and financial capabilities of the owner of the home. It is the facade that affects not only the overall impression of the entire building, but also serves to form the image of the mansion as a whole, and also performs many other practical tasks.

Attention! The amount of funds allocated for finishing the facade should not exceed 10-15% of the total construction cost. Using this simple formula, the client can choose best option for your case.

The building materials market is huge.

The building materials market is huge. The building materials market offers a fairly wide choice for buyers of different social groups and financial opportunities. At the same time, the quality and characteristics do not always directly depend on their cost.

The client can choose from three groups of materials for finishing the facade:

When choosing a product, you need to pay attention to several important factors.

The first is packaging. Boxes with building materials should not be dirty or torn, as a manufacturer responsible for the quality of his products will never allow himself to show such disrespect to the buyer. Also look at the box for information about the product, about the methods of its production and transportation.

In the case of tiles or siding, you can compare several samples at random from different boxes: they must match in quality and color.

Attention! Please note that siding cannot be thicker than one centimeter! It is also important to uniformly color it over the entire area.

Check the package.

Also consider what to buy piece materials(tiles, artificial stone, etc.) is needed at large trading floors, because in this case the possibility of acquiring the same element increases if it is not available at your construction site.

If you have decided on what material is useful to you (natural, synthetic or artificial), then you can be guided by the following principles to finish the house outside with your own hands.

Homeowners who have chosen natural material, most often prefer facing bricks, largely due to the variety of textures and color shades. This material is produced in six formats, which gives great opportunities for creating original ornaments.

It is worth finishing the basement with natural stone and producing landscaping. This material is characterized not only by high cost, but also by massiveness, which creates difficulties in finishing facades. Exclusivity can be achieved with slate, basalt, granite or onyx.

Not every foundation can withstand natural stone cladding

Not every foundation can withstand natural stone cladding Synthetic materials are used mainly in the exterior decoration of economy-class dwellings, the basis for which are cinder blocks or aerated concrete. Finishing is common basement siding with imitation stone or brick. Metal siding is unjustifiably less popular, since it is this material that has rather high durability and color fastness. When using siding, it also becomes necessary to insulate the walls from the outside with mineral wool or polystyrene foam boards.

Of the third group of finishing materials, artificial stone turned out to be the most popular, the main components in the production of which are cement, sand and corresponding dyes.

Artificial stone is rightfully considered the "golden mean" in the selection of materials for finishing the facade of the house. Among the main characteristics it should be noted: quite reasonable price, relatively low weight, antibacterial effect, resistance to influence environment.

The combination of materials is very common: for example, the basement is decorated with artificial stone, and the walls themselves with siding, or the bottom - facing brick, and the rest of the walls - with decorative plaster.

The main stages of the exterior decoration of the building:

Modern industry offers a huge selection of materials for decorating a house outside, but it’s quite possible to do it yourself if you carefully approach the choice of material and its installation. Among natural, synthetic or artificial materials, there is sure to be one that suits you and your building, and the efforts made will make it unique and interesting in appearance.

The exterior of the house is important process, thanks to which you can give the building an attractive appearance, as well as protect it from the negative effects of the weather. It is necessary to choose finishing materials responsibly. No need to pay attention only to its external characteristics. It is important that the finished finish can last a long time and does not succumb to negative atmospheric influences.

On modern construction market Finishing materials for outdoor work are presented extensively. Let's take a closer look at each of the available options.

This finishing option should be attributed to the classic. Due to such cladding, it is possible to protect the walls of the house from the penetration of moisture, the influence of low temperatures. All this prolongs the life of the building and prevents the destruction of the walls.

Plaster for the exterior of the house

Plaster for the exterior of the house For finishing the house, the following types of plaster can be used:

If you decide to do the plastering with your own hands, then it is best to use an acrylic type of material. It belongs to the facade and looks great on the walls of the house, built of polystyrene foam. You can also use plaster for finishing a house made of brick and stone. But for this it is necessary to pre-execute the frame. Due to it, moisture from the aqueous solution will not seep into the pores of the tree.

On video plaster for exterior decoration of the house:

This material for finishing the house is in great demand for a long time. The house, finished with multifaceted ceramics, looks very presentable. In addition, the material under consideration is characterized by such advantages as strength, environmental friendliness, unusual textures and shades.

Polyhedral ceramics

Polyhedral ceramics Thanks to a wide range, the facade of the house can be made original. Clinker multi-colored tiles can also be used when decorating a house outside. This finish does not require careful maintenance, and is also accompanied by increased strength, high resistance to fire, low adhesion and resistance to frost.

This finish option, although quite expensive, has not affected its popularity in any way. The main advantages of the material include reliability, interesting shapes, a wide range of sizes and shapes. Due to such wide variety I manage to turn on all my imagination to the fullest and turn all my ideas into reality.

Fake diamond

Fake diamond Similar properties are inherent in artificial material. It is inferior to the original only in price. In addition, artificial stone is resistant to corrosion, wear, and also has a light weight. Due to the latter advantage, external cladding can be performed even on weak foundations.

Artificial stone can be presented in the following imitations:

Each version is original in its own way. In addition, they have a long service life, frost resistance and resistance to weather conditions. Due to these qualities, the exterior cladding of the house with stone is in great demand.

On the video - artificial stone for exterior decoration of the house:

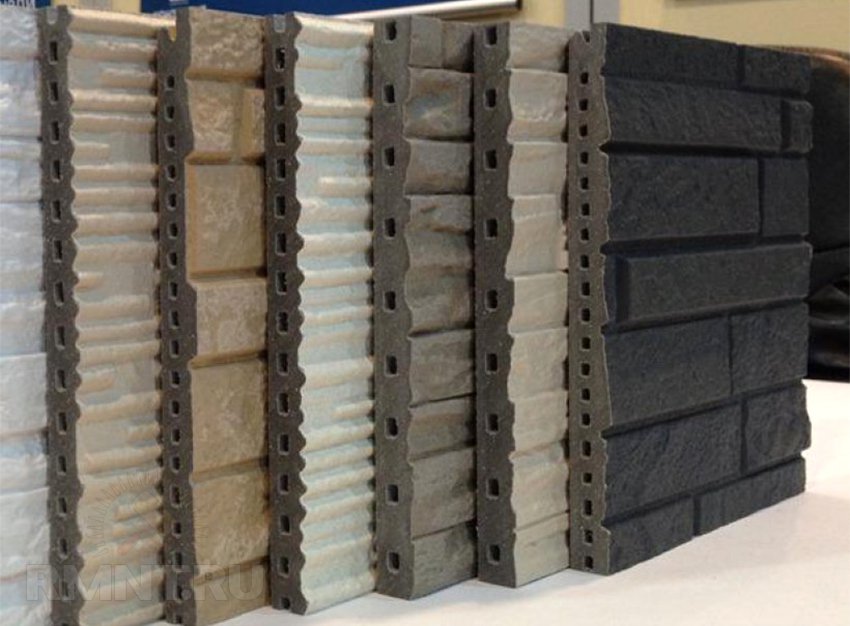

This material is lightweight. They are used for houses that are equipped with problematic ceilings and foundations. The next advantage of thermal panels is the ease of fastening. Installation can be carried out on walls made of various materials - wood, concrete, brick. Finishing can be done at any time of the year.

Thermopanels for exterior decoration of the house

Thermopanels for exterior decoration of the house When installing thermal panels, the walls of the house receive reliable protection moisture and other adverse weather conditions. This material It is highly durable, so no microorganisms, UV rays are afraid of it.

This material is at the peak of popularity today. And there are several reasons for this:

On the video block house for exterior decoration of the house:

When installing siding, it became possible to use vinyl, metal panels. Due to this method of sheathing, plaster, such as finishing material, fades into the background. Due to the exterior decoration with siding, the facade will acquire an elegant look. Plates can take on a variety of patterns and colors. In addition, they provide excellent protection against various conditions bad weather. In addition, due to siding, it is possible to mask various facade flaws, such as cracks. Multi-colored house siding is an excellent choice for those who want to save money and produce installation work on one's own.

Siding for the exterior of the house

Siding for the exterior of the house Suitable siding for any type of foundation. The peculiarity of such a finish is that it is necessary to provide for the installation of such additional elements, like architraves, starting strip, finishing strip, spotlights. If these details are missing, it will be simply impossible to complete the siding.

When choosing a finishing material, it is necessary to take into account what the house was built from. Universal material plaster remains. It is suitable for a building made of wood, stone, brick and even aerated concrete. When choosing a plaster, it must be taken into account that it has the ability to pass water vapor, has excellent water-repellent and frost-resistant properties.

If we talk about brick house, then despite the solid masonry, a large load is placed on the foundation. So thermal panels are perfect for finishing such structures. Thanks to his light weight they are suitable for any type of foundation. And specifications panels are several times superior to brick.

On the video, how to choose the right material:

You can also use siding for a wooden house. Since the siding finish implies the presence of a crate, a unique opportunity is created for the installation of insulation. This will improve the thermal insulation qualities of the house, as well as protect it from adverse weather conditions.

When choosing any material, it is important to take into account a number of factors, including cost, performance, appearance, as well as cost. Right choice facing material and its installation will allow you to get not only an attractive, but also a strong and durable lining.

Exterior decoration is important for a home. It not only gives a finished look and decorates the structure. Facade cladding forms a reliable sound and heat insulation, protects the house from the negative effects of the environment. External finishing prolongs the operational life of the building and prevents destruction, strengthens the structure of the house.

Today they are making various materials for exterior decoration of house facades. You can easily pick up products by quality, price and appearance. When choosing a material, performance and aesthetics must be taken into account.

quality facade materials for exterior wall decoration, houses must protect the building from the effects of wind, steam and moisture, and temperature changes. The cladding must be resistant to the appearance of fungi and mold, which lead to the formation of cracks in the house. In addition, it should harmoniously fit into the landscape. suburban area. In this article, we will take a closer look at the types facing materials release today.

Plaster is a familiar and common finishing material that is used for work both inside and outside the house. Decorative plaster for the facade is distinguished by its availability and low cost, a wide selection of colors and textures, resistance to moisture. At right technology installation, the material tolerates temperature extremes well, does not burst in frost and does not crumble over time. The ease of applying plaster will allow you to do the installation yourself without the involvement of specialists.

There are several types of plaster, including mineral, acrylic, silicate and silicone. Let's look at the specifics of each:

Siding - modern material, which has gained popularity due to its availability and low price, easy installation and aesthetic appearance. Panels are easy to install. They look neat and harmonious. In addition, they are versatile. Siding is used for finishing buildings from any materials. It is easy to clean, effectively protects the structure from negative impacts external environment.

Released today the following types siding:

Before installing the siding, the wall surfaces are prepared, cleaned old finish, dirt and dust. Then a crate of bars is installed, which are placed at a distance of 0.5 m from each other. The crate will provide proper ventilation. In addition, insulation, waterproofing and vapor barrier films. Panels are already attached to the crate from above.

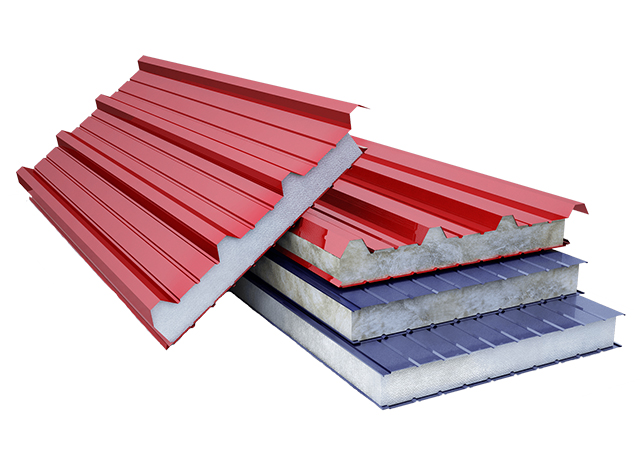

Such panels represent two or three dense layers, between which a heater is laid. It's aesthetic attractive material with a variety of color choices. It is light weight, fireproof and durable, resistant to moisture and suitable for repair. If one of the panels is damaged, you do not need to renew the cladding completely, it is enough to replace the damaged panel.

Used as insulation in sandwich panels mineral wool, polystyrene foam or fiberglass. The panels themselves are also made from different materials, among which:

A big plus of sandwich panels is that they are already insulated. This allows you to save on heating and insulation of the house. The material features easy installation in short time. However, during installation, it is important to comply with technologies and norms, otherwise the material will quickly become unusable, and the thermal insulation qualities will greatly decrease. Do not use sealing tape during installation. Otherwise, the joints of the panels will freeze through.

Decorative material with a wide choice of colors and textures can make a home original and unique. Porcelain stoneware characterizes strength, wear resistance and durability. It is resistant to moisture and low temperatures, abrasion and mechanical damage. The material does not burn and does not lose color during operation. Porcelain stoneware will provide reliable and quality finish, will allow you to embody the most daring and interesting design solutions.

The following types of porcelain tiles are produced:

Among the shortcomings of the material, we note the specific and complex installation. Porcelain tile is fixed on a special glue or metal carcass. Under no circumstances should material be installed on cement mortar, as it will fall off in the cold.

Clinker brick looks like building brick. This is a natural material that is made from clay and natural dyes. They produce bricks for the facade and sidewalk. In addition, there is a clinker tile, which is also made from natural raw materials. Today you will find hundreds of types of material with different textures and colors. The surface can be embossed, corrugated, glossy, matte or glazed.

Clinker materials do not absorb water and are easy to clean. They are strong, durable and resistant to use. household chemicals when washing. Tiles and bricks endure frost, aggressive impact ultraviolet and temperature fluctuations. However, the materials are expensive and difficult to install.

Sometimes natural or artificial stone is used for the exterior of the house. This is an expensive cladding, but reliable and durable. Artificial products are cheaper and more diverse. From natural stones, marble and granite, basalt and sandstone, slate and other types are used for decoration.

Another view facade decoration- metal cassettes. Such cladding is used for ventilated facades. It is a reliable and durable material, resistant to mechanical impact and the negative impact of the environment. The market offers a wide range of colors, textures and sizes. The only drawback of metal cassettes is the high cost.

Whatever finishing material you choose, it is important to carry out the installation correctly. Failure to comply with building codes and regulations will lead to the rapid destruction of the cladding. The facade will lose its former appearance. In addition, cracks may appear on the walls of the house, and the structure will begin to collapse. To avoid such problems, contact the professionals!

MariSrub experts will select high-quality materials, perform facade finishing work reliably and promptly. We carry out construction wooden houses and baths, conduct and connect network engineering on land plot, we make the inner and exterior finish"Full construction"!

Facade panels for exterior decoration are installed for various purposes: for decorative effect, strengthening thermal insulation, protection against mechanical damage. Let's talk about the types, installation methods, manufacturers and prices - the main parameters for choosing panels for use in individual construction.

Why are facade panels attractive and why are they readily used in private and civil construction? How to find the optimal material that meets all the tasks? First, we note the merits of this architectural technique, and then we consider and evaluate the possible options.

If the material of the walls is quite decorative, an excellent heat insulator, and is not afraid of scratches and chips, then additional finishing is not required. But when design improvement is needed or consumer characteristics, panels will help solve many problems.

Their common advantages for all types:

However, each of the types of panels, differing in design and material, has its own advantages, disadvantages, installation recommendations and price range.

Panels can be classified according to the following parameters:

Design solutions may include one or more finishes. Sometimes the contrast of smooth and convex textures, dark and light shades, highlighting windows, cornices, columns, small color or texture accents look more impressive.

These facade panels are made from aluminum alloys and steel. Aluminum is lighter, but steel, with the same thickness, is more durable - it does not deform upon impact. The outer surface of the metal panels may have polymer coating on different basis– polyester, pural, plastisol, can be dyed powder paint, decorated with crumbs of natural stone.

By themselves, these panels do not increase thermal insulation characteristics walls, but can serve as the basis for the installation of thermal insulation, the organization of ventilated facades. When combined panels a heat-insulating layer is added to the outer metal layer - for example, from foam. Aluminum and steel composite panels are popular, consisting of two layers of metal with a layer of plastic or mineral wool. They have greater rigidity and durability, heat and sound insulation properties, are presented in all colors.

Installation of metal facade panels most often it is carried out on a crate or special guides using nails or special fasteners - clamps (stationary and sliding). Sliding clamps are used on large-sized panels, given the relatively high thermal expansion of metals. The design of the connecting edges provides sufficient tightness, but experienced builders It is recommended to join the panels horizontally for greater reliability.

Modern finishing material, thermal panels - beautiful, durable, moisture resistant, easy to cut with a grinder, excellent insulation, inert to mold and fungi, can be mounted on their own.

Clinker tiles, which are burnt red clay, make up the outer layer superimposed on a base of polyurethane foam, polystyrene foam or expanded polystyrene. External tiles, in addition to clinker, can be porcelain stoneware or glazed ceramics. Porcelain stoneware large-format products can be used independently - without insulation. In this case, they do not belong to the category of thermal panels and are mounted on ventilated facades.

Facade thermal panels according to geometry and purpose are: straight, angular and additional, they differ in the thickness of the heat-insulating layer (30-100 mm). The number of layers of material is 2-3 (they may have a reinforcing layer of pressed wood chips or stone chips on the back side). Docking of panels among themselves: tenon-groove. Such material can be finished with both straight and rounded walls.

Mounting methods:

Joints of plates and seams between tiles (if necessary) are recommended to be additionally treated with frost-resistant grout. If the surface of the slab does not need additional grouting, the joints can be insulated with sealant or gently foamed. Due to the seamless design and installation, cold bridges are not formed, and atmospheric moisture does not have access to the walls.

Such products can be one- and two-layer, where the second layer is foam insulation. beautiful material, with a rich palette, with imitation of wood or stone, light, strong enough, and inexpensive compared to other materials. Can be installed independently. The main disadvantage is flammability. The barbecue area is best located away from the walls of the house. Some panels may be more brittle when severe frosts. The most common representatives of the category are polypropylene and vinyl panels.

Installation is carried out on a prepared surface (cleaned and leveled). wooden walls should be treated with antifungal agents.

If the panels are single-layer, if additional insulation is necessary, it is necessary to consider a crate that provides the possibility of laying thermal insulation materials. Install vapor barrier and/or wind barrier membrane. Installation plastic panels performed on a crate or guide profiles made of aluminum.

Also used for façades fiber cement panels(sometimes called Japanese), some of which it is desirable to finish with plaster or enamel for outdoor use - to reduce hygroscopicity. The composition of products includes wood or artificial fiber (fiber), cement, quartz sand and mica.

It is an eco-friendly, frost-resistant, non-combustible material with a thickness of 14-35 mm. Due to the inclusion of fibers, the strength of the panel increases, and the content of many microscopic air bubbles or structural hollowness enhances its heat-insulating properties.

Panels are installed on metal crate and may include the installation of an additional layer of thermal insulation. Mounting elements: nails, self-tapping screws, clamps, rivets. The seams are foamed, treated with sealant or grout. When performing all work, it is necessary to protect the respiratory organs, eyes and hands, and to cut the panels in the open air.

Wooden panels often repeat the geometry of the lining or natural timber. The surface color can vary from carbon-graphite to almost white, imitating expensive and rare wood.

Relatively new material based on wood flour - a wood-polymer composite that combines the advantages of all the components that make up its composition. It burns reluctantly, resists mold, is protected from insects, fades slightly in the sun, does not leave splinters.

The processing of WPC panels is similar to working with natural wood. Fastening wooden panels conducted in warm weather, according to the technology of a ventilated facade on a crate - wooden or thick-walled metallic profile(galvanized steel or aluminum) using stainless hardware and clips.

Panels made of wood fibers pressed at high pressure and temperature, also have the advantages natural wood and devoid of some of its shortcomings. Their outside surface covered natural veneer, which requires a fairly careful attitude in terms of mechanical effects.

In addition to those listed, there are natural stone panels, glass panels and others that are too expensive and difficult to install to be widely used in private housing construction. Sandwich panels, on the contrary, are used more often in the construction of secondary buildings, such as garages. At the same time, such panels can be the main, load-bearing material of the walls.

Special attention should be paid to plinth panels. To their mechanical strength higher demands are made. Often the corners of the building are also trimmed with this material.

Attention! When purchasing everything for the facade, consider the area, the number of corners, the pitch of the crate, additional materials - heat and vapor barrier, plaster, grout, sealant. Buy everything with a margin of 10-15% for cutting, losses. Prepare the mounting tool.

In addition to evaluation performance characteristics and preferences in terms of decor, when choosing, users take into account the brand and price of facade panels.

The table shows brands and their products that regularly enter the ratings and TOPs of popularity among consumers.

| Brand | A country | Panel type | Price, rub./pc. | Area, m2 |

| Docke-R | Germany-Russia | Polymer - for brick, stone, clinker tiles | 350-530 | 0.37-0.45 (useful) |

| fineber | Russia | Polypropylene, PVC - under brick, stone, slate | 400-560 | 0,49-0,52 |

| Alta Profile | Russia | Polypropylene - for stone, brick, clinker and glazed tiles | 390-520 | 0,56-0,53 |

| Holzplast | Germany | Polypropylene - brick, stone, slate, tile | 425-510 | 0.476 (useful) |

| VOX | Poland | Vinyl MAX-3 - colored, wood effect KERRAFRONT - PVC hard + foam - wood effect Polymer Solid - under brick, stone |

430 2000-2700 420-450 |

0,96 0,54 0,42 |

| Nichiha | Japan | Fiber cement - a huge choice of design ART-series EX series, 14 mm W series, 16 mm |

1180 840-3800 1370-3100 |

0,1 0,828-1,378 1,342-1,378 |

| Nailite | USA | Polypropylene - under a stone, a brick, a tree | 830-900 | 0,465-0568 |

| termosit | Russia | Thermal panels with clinker tiles (Poland) with clinker tiles (Russia) |

1040-1180 980-1120 |

0,63 0,58 |

| "DKM-facades" | Russia | aluminum composite | 900 | 1,0 |

| ALCOTEK® | Russia | aluminum composite Steel composite |

from 500 from 1100 |

1,0 1,0 |