Very often basement on screw piles in open form it is perceived as a hut on chicken legs and, although this does not affect the quality of the building at all, it is best to close it with some decorative finishing elements. In such cases, there are many options - no less than for the walls themselves, because construction market is currently very rich in building materials.

Below we will talk about some of the options for such finishes, and also, as an addition, watch the thematic video in this article.

Note. Such a finish needs not only the base of the screw foundation - any base that is devoid of decorative cladding, does appearance buildings unfinished.

So, our task is to close the base for screw piles with our own hands, and for this you can use many materials. Nevertheless, the essence of the arrangement is very similar to one another, since the principle still does not change.

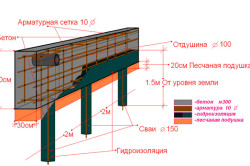

One of the options is when the basement on screw piles is sealed using a low grillage. That is, when installing such a foundation along its perimeter, a trench up to 30 cm deep is excavated and a tape is poured, where top part protrudes 10-20 cm above ground level. So you get a pedestal for laying bricks, which, in turn, will serve as the basis for tiles or plaster.

Here you will get, as it were, two foundations in one - screw and tape, but such a combination will not only allow you to easily close the piles, but also increase the strength of the foundation. In addition, concrete is poured with a light reinforcing cage - as a result, the tape will not crack and will also serve as part of the decoration of the lower part of the house.

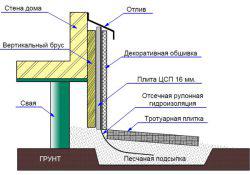

You can see another option in the photo above - this is the installation of crates on piles under any sheet material. AT this case, these are stone panels, but with exactly the same success you can mount a composite or siding on them. Here you see two wooden profiles, but there may be more - everything will depend on the finishing material.

The crate here does not have to be installed from wood - more often it is made of metal, and for this they can be used metallic profile 20x40mm or even CD which is used for drywall installation.

Fixation can be done directly on piles, but it is convenient for timber and metal, where the first is screwed and the second is welded. For CD, it is best to weld ears (metal plates) onto the piles, on which brackets can be fixed.

Corner 120 × 120 mm serves as a base for bricks

There is another way to close the void under the building, and its price will be much less than the arrangement strip foundation. A corner of 120 × 120 mm is welded to the piles, which will serve as the basis for the front brick, where the width of the bed is just 120 mm. The corner is welded strictly according to the level, and if the site goes at an angle, then in the upper part it is better to go deep into the ground so that there is no void.

Before laying decorative brick, the corner should be primed to reduce the possibility of rusting to a minimum. The construction of the plinth is carried out as ordinary masonry with a spoon dressing and with a seam of at least 5 mm.

After you raise the entire perimeter, you need to put ebbs on top, which can be decorative, that is, from a brick set, or make them yourself and galvanized sheet, but the first option will look much better.

You may also have and for this you can use extruded polystyrene foam. A trench 20-30 cm deep and wide is dug along the perimeter of the building on the bayonet of a shovel and a crate is mounted on the piles. Then you attach sheets of insulation, on which you can lay tiles on top or cover them with sheet slate, as shown in the photo.

Recommendation. After closing the space under the building, condensation will form, which can cause mold and rot.

To prevent this from happening, the instruction recommends making ventilation vents around the perimeter with a cross section of at least 8-10 cm.

This applies to any of the finishes, as they all stop the movement of air.

In conclusion, it should be recalled that the finishing of the base of the screw foundation does not end with its closing. The fact is that moisture from atmospheric precipitation will leak under the bottom and this can do a bad job for the building - water will accumulate there. Therefore, in any case, along the perimeter, you need to make a simple or decorative blind area for water drainage.

A pile-screw foundation is much cheaper than the simplest strip foundation, it is built much faster, and at any time of the year and does not depend on the topography of the site. Its only significant drawback is the unattractive empty space between the ground and the first floor.

To eliminate this shortcoming, resort to various methods finishes.

Screw pile - metal pipe with a thread on one end and a flat head on the other, somewhat reminiscent of a huge nail. Piles can reach a length of 2.5 m, have blades at the end, and not threads or threads throughout the body. To prevent corrosion, the products are covered with ship primer - black.

The empty space under the building not only looks unaesthetic, but also poses a threat to the structure. Evaporation of wet soil, snow and rain getting under the building, grass sprouting - all this contributes little to the preservation of the building, and small animals - from lizards to cats, willingly use this space.

On the video finishing socle pile screw foundation:

Finishing allows you to solve the listed problems. General principle cladding is very simple and does not require costs.

Brick, basement siding, and even simple plaster are used as cladding.

This is the most expensive method, and it also requires certain knowledge and skills. If they exist and the costs do not frighten the owner of the building, then this option is easy to implement. It has a lot of advantages:

The disadvantages include the cost of such a solution and the duration of installation: masonry takes time.

This option successfully imitates brick and masonry, but at the same time it differs in much less weight and costs much less.

Socle siding is a vinyl panel of increased strength and rigidity. Distinguishes and more reliable method docking and high resistance to wind loads.

Their advantages are:

The only drawback can be called that, in terms of durability plinth panels still inferior to brick.

This is a metal profiled sheet with a zinc coating that protects the steel from corrosion. Dyed in the most different colors, has a thickness of 9.5 to 0.7 mm and is more than affordable.

Material advantages:

Product disadvantages:

On the video, finishing the base of the pile screw foundation with corrugated board:

This option can only be implemented together with basement insulation. Its essence boils down to attaching heat insulator plates made of dense material to the frame and applying a plaster layer on them.

Plates are pre-primed. As plaster mixture it is better to use silicone or fiberglass, as they are most resistant to moisture.

The disadvantage of the pile foundation is a rather cold floor. And if in the southern regions it big problem does not, then already in the middle latitudes the base has to be insulated.

There are many methods of warming. The choice is determined by the height of the pile columns, their location, the material of the piles and the topography of the site.

There are 2 fundamentally different approaches:

On the video insulation pile foundation plinth:

Regardless of which material is chosen for thermal insulation, the general sequence of actions is almost the same.

On the video process full insulation:

Not every material is suitable for basement insulation. Proximity to the ground means very high resistance to moisture, mechanical strength and excellent thermal insulation properties.

Preference is given to synthetic materials. Firstly, they do not attract rodents, and secondly, they are highly moisture resistant and not susceptible to mold. Minvata is excluded unambiguously. Basalt can be used, but is very inconvenient during installation.

Penoizol has similar characteristics. But unlike polystyrene foam and polystyrene, it allows steam to pass through without passing moisture.

The disadvantage is the same - a rather high price. You also need to take into account the large weight of the product.

Brickwork serves as both a heat insulator and decorative trim plinth. Despite the high cost, this option is often the most profitable.

Finishing and insulating the basement of a pile-screw foundation is not so difficult. Apply for this different materials, which allows you to select the best way for every case.

The pile foundation is fundamentally different from a monolithic or tape structure. Its peculiarity lies in the fact that the pile heads are not recessed into the ground, but are the above-ground part of the foundation.

And no matter what type of piles was used - the essence of this does not change. To give the facade a pleasant appearance, the space that forms between the ground surface and the base of the house must be closed.

We will tell you about how the lining of the pile foundation is done with our own hands in this article.

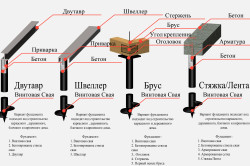

If the house is being built brick or block, pile field usually crowned with a reinforced concrete grillage. The basis for wooden and frame-panel houses is a steel channel, or timber.

So:

Considering that not only residential buildings, but also various outbuildings: baths, sheds, temporary huts, then you can close the space under them in the simplest and cheapest way.

So:

In this case, brick walls they make not decorative, but ordinary ones, one and a half bricks, and even with insulation. There is comprehensive information on this topic on our website, and now we are talking about the device of a false base.

Since any panels are mounted on a frame, it is necessary to start with its installation. In the simplest version, a 40 * 100 board, or 40 * 40 bars, is used for its installation.

The size of the elements of the crate, and the number of its belts will depend on the height of the plinth and the weight of the panels:

Well, each type of panels is fixed to each other in different ways. It depends on their design.

Usually, when buying a product, an instruction is also attached, and no one has problems with installation.

Made on screw piles, it consists in decorating the basement of the supporting structure of the building. Finishing is the final stage of building a house.

Facing the foundation on piles can be done in the following main ways: building a hinged basement, creating a strip foundation around the perimeter of screw piles, cladding basement siding, finishing with natural stone, lining the screw foundation with mosaic plaster.

The screw foundation is widely used in the construction of light structures. This type base is versatile due to the fact that it can be installed even on unstable ground, where the level ground water elevated, on slopes and nearby trees.

Facing the foundation on piles can be done in the following main ways:

Each method has its own advantages, but differs in cost and scope of work.

The essence of this method lies in cladding with sheet finishing materials that are mounted on wooden or metal rails. This technology consists of the following steps:

The arrangement of a hinged plinth is justified by its such advantages:

Back to index

The technology of this method consists in arranging a strip shallow foundation around the entire perimeter of the pile-screw base of the house. Brick or cinder block masonry is laid out on this structure, in order to later veneer it decorative materials. The sequence of work of this technology is as follows:

The advantages of the strip foundation are:

In addition to these advantages, there are a number of limitations to the use of this finish:

Back to index

Lining the foundation with natural stone is a reliable, expensive and sophisticated method.. This method suitable for foundations on screw piles, as well as for other types of foundations.

The advantages of such a finish are huge:

The disadvantages include:

Only durable rocks of stone are suitable for finishing the foundation: granite, labradorite. It is better not to use marble and limestone, since these materials are quite soft and porous and their protective properties weaken over time.

Comments:

At the final stage of construction, some homeowners are trying to resolve the issue of how to properly clad the foundation on screw piles, which in recent times are gaining more and more popularity. The basis of the house on screw piles has gained wide popularity due to the fact that this foundation design has proven itself in the most difficult operating conditions. It can be applied to almost any type of soil, and even if it is characterized by a fairly strong unevenness.

After erecting the foundation and building the house, it is necessary to come to grips with the lining of the basement. It not only gives the house a beautiful appearance, but also gives additional strength to the foundation.

Simple technology, high reliability, excellent efficiency and versatility are the main characteristics of this type of foundation for any structure, which are increasingly attracting adherents of such a foundation, and can be not only professional builders but also self-taught.

Screw piles are widely used not only to create the foundation of a building, but also to build a reliable support for fences, gates, etc. They are perfect for doing construction works on rough terrain with difficult terrain, for example, if your construction site will be located in an area that is in close proximity to the reservoir.

Moreover, it is possible to install and revet the foundation on screw piles throughout the year. At the same time, you do not need to spend money and time on leveling the ground in the territory allocated for construction. After all, this can be done only with the help of special equipment. It should be noted that for rent, and even more so for the purchase of specialized equipment, you will need rather big funds.

For the construction of houses using Canadian technology, a screw foundation is the most suitable solution, but you need to know that its device is still not possible everywhere. Stony soil, for example, is one of the main contraindications to the use of such technology. When building on silty soil, which is characterized by a liquid soil consistency, and on deepened peat bogs, one should responsibly consider the calculation and direct installation of piles.

Thus, before proceeding with the construction of the foundation of a building on piles, it is necessary to carry out exploration drilling. This will determine the bearing capacity of the soil and the screw piles mounted in it.

The excellent characteristics of the foundation on screw piles in comparison with other foundation designs for various buildings are as follows:

Experts say that the foundation of the structure on screw piles has a high bearing capacity, moreover, such a structure is able not only to withstand any load, but also to withstand fairly strong frost heaving of the soil.

Significant increase bearing capacity screw pile is due to the fact that during its installation the soil is not weakened at all, since when screwing the interturn intervals, it is compacted with the help of pile knives. Screw piles are very resistant to groundwater and external precipitation (rain), so there is no need to build a deep drainage system, which is prerequisite during the construction of a concrete strip foundation.

It is allowed to build the foundation of the house with the help of screw piles throughout the year, which is important when constructing buildings in the northern latitudes, where another type of foundation design is absolutely not applicable, since the soil has a too deep level of freezing.

Finally, a foundation of this kind is built within 1-2 days, and its service life, according to experts, is at least 80 years.

One of the main negative characteristics of this technology for creating the foundation for a house is that the foundation structure on screw piles has an underground space, and this, in turn, contributes to the penetration of cold air from below, which will certainly affect the comfort and microclimate throughout the building.

The implementation of thermal insulation of the foundation on screw piles has its own characteristics. First of all, a structure is created like a missing basement, which is subsequently insulated. Warming must be carried out in a complex - from the inside and outside.

So, the whole procedure of thermal insulation is divided into the following stages:

The first method involves digging a small recess (150-200 mm) between the support posts, then pouring a reinforced foundation in it. After it seizes, it is necessary to lay in half a brick and glue the insulation material on this wall.

The second method is to fix wooden beams on piles in a horizontal position with bolts or metal guides, but then you will already need welding machine. After that, sheets of insulation are attached to the constructed structure. According to experts, the insulation can also be fixed directly on the cladding material. As a material for insulation, it is best to use foam or polystyrene foam. In addition to excellent thermal insulation properties, these materials have good sound insulation.

The process of arranging the foundation on screw piles ends with the help of various facing materials, these can be decorative panels, siding, natural or fake diamond, decorative PVC panels, etc. For cladding, many homeowners use combined thermal panels or wet facades often used for this purpose ceramic tile, mosaic plaster or facing brick.

When starting to facing the basement of a pile foundation, one nuance should be taken into account. A certain gap must be left between the surface of the earth and the decorative finish, this is the only way to prevent damage to the finishing material when it swells into the soil. On average, this gap should be approximately 50 mm. Of course, its value can be increased or decreased, it all depends on the degree of swelling in the soil in a particular area. If desired, this gap can be closed with metal mesh or other material that will prevent pets from entering under the house.

Proper cladding of the foundation includes the creation suitable conditions underground ventilation. To ensure a normal ventilation cycle in facing material special holes are mounted, with their help air will penetrate into the underground room, creating in it favorable conditions. It should be noted that such openings must be left open even in winter.

First of all, it is necessary to make a basis for future finishing. To do this, steel or wooden slats, which are subsequently sewn up, for example, with a decorative panel or siding. The bars are attached to screw piles from above and below. One of the most common materials is decorative panel, which perfectly imitates stone, wood and other natural and artificial materials.

To positive moments hinged socle on screw piles is that for its construction you will spend much less money than in comparison with the creation of a shallow foundation.

The next positive factor of the hinged plinth is that its installation is quite simple and takes very little time.

A hinged siding plinth will perfectly protect the building from dampness and mold.

So, finishing the foundation on screw piles is not difficult, even a beginner can do it.