It often happens that you purchase a door frame along with the door. But there is a more economical option -. In addition to saving money, the need to make the frame yourself may arise when the purchased door comes with a frame that is not quite the right size.

By making the door frame yourself, you will save quite a large amount of money.

In order for a door frame made by yourself to be of high quality and durable, you will need a machine designed for processing wood. As a material for the box, you need to purchase a planed board. It is from this that parts will be cut out that match the width and length of your doorway. But let's talk about everything in order. Before you start making the box, you will need to purchase necessary materials and tools, take some measurements and only then think about how to make the box. All this will be discussed in more detail below.

So before you start independent process making a door frame, you need to acquire some tools and materials that may be needed when performing this work. This list includes:

The wood for the door frame must be well dried so that it does not warp later.

One of important stages Making a door frame with your own hands involves choosing a suitable and high-quality material. Below is a list of materials that are most often used for these purposes, which means they are the most in demand and popular.

A metal frame is most often used for an entrance door.

Since the most popular and widespread material is wood, we will consider the manufacturing process of a wooden box.

Most of all, according to professionals, laminated wood coated with plastic is suitable for these purposes. The service life of such material is characterized by enviable durability and does not require additional processing. Untreated wood is also used in the process of making a door frame, but keep in mind that additional effort will be required to make it aesthetically pleasing. appearance. Positive quality The 2nd option has the highest strength indicators compared to the first.

Another material that is suitable for making a door frame is fiberboard. However, the strength of this material leaves much to be desired. If you use it for work, be prepared for the fact that the door frame will not serve you for long and will have to be repaired or replaced pretty soon.

First of all, you need to think about choosing the right material. When making a purchase, pay attention to the quality of the board; it must be dry. If you have lost sight of this fact, then during the process of work and operation, you may be faced with unpleasant surprises that cause difficulties in eliminating gaps. Another factor that is worth paying attention to when choosing a material is the presence of defects on the wood in the form of dark (usually blue) spots. Their presence indicates that the tree was dried incorrectly. Don't expect that they won't be noticeable after painting. Usually stains of this origin are visible even under a layer of paint.

After selecting and purchasing the material for the box, you need to take care of preparing the parts in draft. They are cut with a small margin, after which it is time to process them on a woodworking machine. After this procedure, they correspond to the size you need.

The next stage is careful marking. This is the most important and responsible area of work.

Having outlined everything you need, you can move on to the so-called cutting. This procedure involves removing 1/4 of the door leaf. For these purposes, you will definitely need a machine such as a vertical router. The next procedure is to make the grooves necessary for joining the parts of the future door frame. These are cross and standing boards.

After carrying out this procedure, you need to sand the resulting blanks well, after which it is time to assemble the door frame.

Ready assembled box lay the door and estimate the gaps, then adjust them. Usually the gap is removed by trimming the door. There are situations when this option is not possible, for example, when finishing a door with decorative veneer. In this case, the gap is calculated at the preliminary stage, before the box is marked.

As noted above, you first need to take some measurements. These are measurements from the sides of the existing door plus 5 cm on each side. The next measurement involves measuring the top of the door and the bottom (threshold). You also need to add 5 cm.

Next, make a simple calculation, after which you begin directly to work. To do this on flat surface(can be on the floor) place the bars from which the side parts of the box will be made. They need to be positioned so that the grooves are at the top at the same level.

Now you need to make markings touching the upper as well as the lower border of the existing door. The size of the threshold and the crossbar at the top is added to the result obtained. It is necessary to make notches along which the cut will be made. Then cut the parts of the box. When the blanks are completed, you need to fit them to your door.

Take one of the parts and make the grooves on its surface necessary for hanging hinges. For this job you will need a chisel and a hammer. Before doing this work, you need to decide which way the door will open.

The box is assembled using fasteners such as screws and nails.

Only in this case will it be reliable and qualitatively durable. The following procedure involves hanging the hinges and then installing the door in its place. Having done this, it is necessary to make adjustments to eliminate the gaps.

That's basically all there is to assembling the door frame. If such work seems impossible to you, then it would be more correct to buy a ready-made structure or use the help of specialists. Their assembly will be distinguished by speed and quality, and you will always be able to make a claim if necessary.

IN full set door block includes canvas, box and hinges. It can be difficult to purchase a ready-made complete set, so there is nothing left to do but make a door frame with your own hands from profiled timber or entrust this task to specialists. The box, most often, has to be selected separately, and it is not a structure ready for installation, but several elements that need to be adjusted in accordance with the size of the opening, the necessary cuts made and assembled. Door frame It’s not so easy to assemble with your own hands, so in addition to tools, it would be nice to have at least a little carpentry skill.

Wood

Wood  MDF

MDF

The frame serves not only as a frame for the door leaf, but also as a load-bearing base. The strength of the entire structure and its durability depend on the quality of the material and installation of the product. The choice of material depends on the purpose of the door and the material of the leaf itself. Metal-plastic and metal doors They are usually supplied fully equipped, so we will consider only those cases where the door frame has to be manufactured independently. As a rule, in this case we are talking about two types of material: wood and MDF.

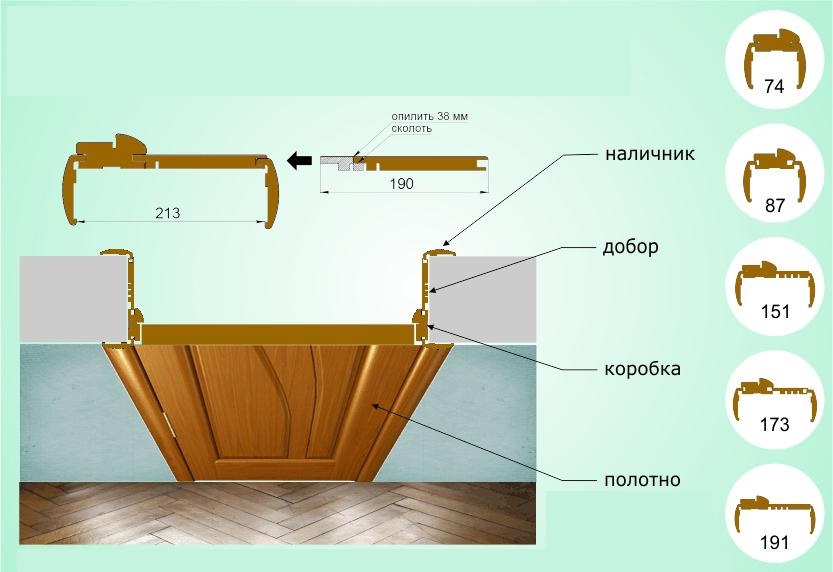

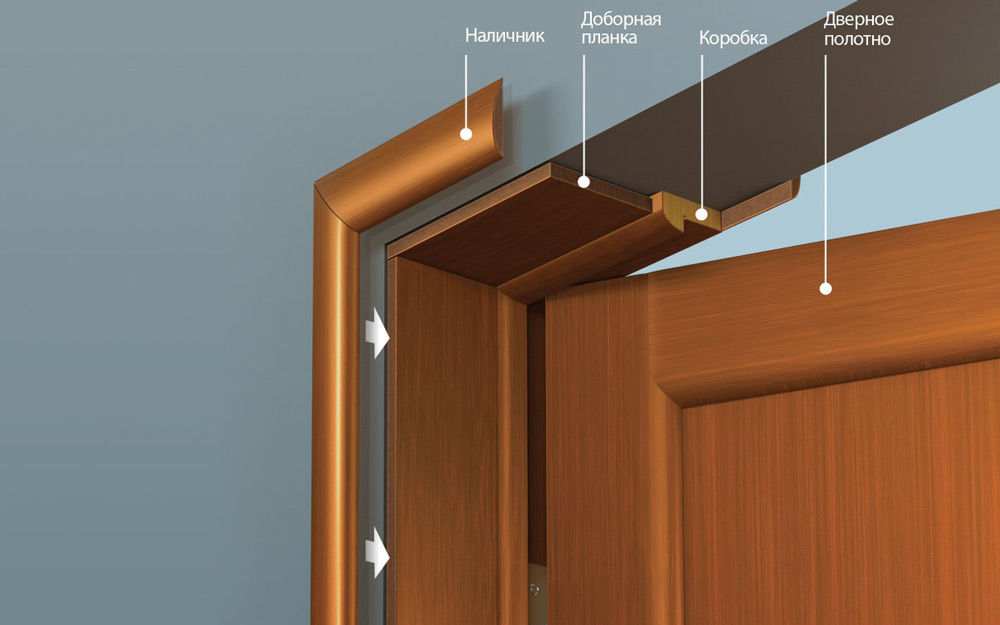

The door frame consists of several slats: two side, top and bottom, if the design includes a threshold. If the depth of the doorway exceeds the corresponding parameters of the timber, your kit must be supplemented with extensions that will increase the depth of the box.

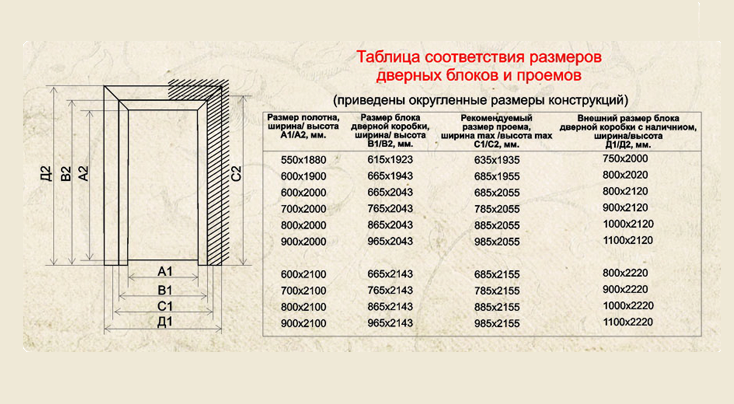

Standard door block sizes vary in width and height. The correspondence of the parameters of the door leaf, block and opening is indicated in the table.

Do-it-yourself door frame assembly is carried out taking into account the following points:

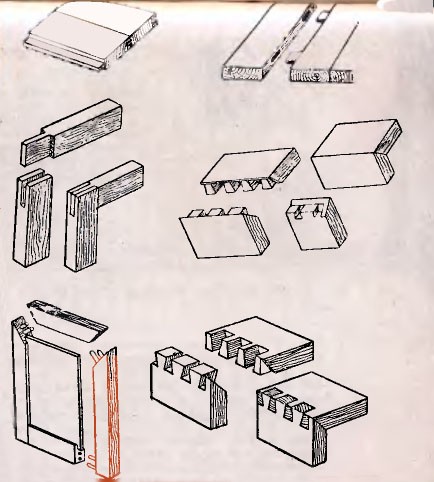

The main difficulty in assembling door frames is the connection process individual elements. The joining of horizontal and vertical strips of the product can be done in two ways:

The joining of the planks is carried out using tenon joints or galvanized self-tapping screws. The figure shows options for tenon joints, which clearly show how to assemble the door frame yourself to ensure high strength of the joints.

When calculating the parameters of the length and width of the profile slats, it is necessary to take into account that the length of the tenon should be equal to the thickness of the box beam. The tenon joint provides sufficient strength to the finished structure, but if desired, additional reinforcement of the joints can be made with zinc-coated nails.

Let's look at how to properly assemble a door frame . As source material we will need profiled timber made of natural wood or MDF.

The box is assembled in the following order:

To secure the assembled frame in the opening and install the doors yourself, you must perform the following steps:

Tip: Before foaming, you need to clean the surface from dust and moisten it with water from a spray bottle. These measures can significantly increase adhesion.

Another important condition To avoid disturbing the geometry of the frame during the installation process, use spacer wedges that correspond to the width of the box and are inserted across it.

The final stage of installing the frame and door is decorative design opening with platbands.

Do-it-yourself door frame is not like that difficult task, as it might seem at first glance. Of course, it will take effort to bring out correct sizes and process the material. If you follow the correct algorithm for carrying out work, everything can be done very quickly, which will allow you to save not only money, but also precious time.

The box is load-bearing element door design

A door frame is a special part of the doorway design structure, which essentially acts as a load-bearing part when installing the door leaf. It looks like framing the inside of the opening. It is to this that the hinges are attached, on which the door is subsequently hung, and the counter plate is also mounted when installing the lock. It is impossible to install a door without a frame. The condition of the structure as a whole depends on the quality of installation and the strength of this element.

The box consists of several parts: two side frames and a crossbar. If necessary, you can use extensions and thresholds. Since you plan to make the door frame yourself, it is necessary to consider the full list of work, starting with the selection of materials and ending with the installation of the finished product.

The door frame consists of individual elements

If you decide to do everything from scratch with your own hands, you first need to choose suitable material for loot.

It is imperative to take into account the size and weight of the canvas, since the main load goes directly to the frame.

The most commonly used materials are:

The most popular option is wooden box for the door, if you make it yourself. Pick up suitable bars won't be difficult. On the building materials market you can find already prepared wooden parts for constructing the frame of the opening. All that is required from the master is to adjust the dimensions and carry out processing.

Wood is distinguished by its durability and environmental friendliness. It is quite simple and convenient to work with. However, the type of wood used should also be taken into account. Pine is usually used, but it is a soft variety, and therefore it is not particularly durable. It is better to use oak for entrance doors. Although its cost will be higher, it will last much longer.

Solid wood door frame

As for other materials, MDF is better use for interior designs. If uncoated parts were used, care must be taken to properly protect the edges. Metal is the leader in strength, but it is more difficult to work with and it looks rougher, so it is used only for entrance doors.

The manufacture of a door frame, in particular done by hand, begins with taking measurements. It is advisable to carry out this procedure after removing the old frame and preparing the surface, otherwise inconsistencies may arise when installing a new door.

In order to construct a box with your own hands, you need to measure the length of each side, that is, the height of the opening, as well as the width in several places. In the future, it will be necessary to create an even perimeter, and eliminate all differences when installing the tray. The diagonal serves as a check digit; its size should also be written down. Another important figure is the width of the box itself. It depends on the thickness of the wall.

When taking measurements, it is necessary to take into account all structural elements and the gaps between them

The manufacture of the box largely depends on the correct execution of this stage of work. It is necessary to transfer the dimensions to the material and cut the parts in accordance with the data received. In this case, the method of connecting the elements of the trap should be taken into account. Reliable way clutch wooden parts– grooved. It is quite difficult and time-consuming to cut such a connection with your own hands, so you can find ready-made parts.

Since you need to make the door frame yourself, it is easier to use the second connection method - diagonal. To do this, all elements joining each other are filed at the edges at an angle of 45 degrees. To do the job with an accuracy of a degree, use special tool- miter box. Check the dimensions not only in relation to the opening, but also the door leaf itself. Consider the presence of a threshold in advance.

Since you need to make a door frame with your own hands not only durable, but also beautiful, you need to take care decorative processing material. However, before this, it is recommended to carry out additional manipulations, especially if we are talking about wood. It is necessary to provide it with proper protection from moisture, fungus and insects. To extend its service life, the wood is coated with a layer of special impregnation.

It is necessary to leave a small gap between the door and the frame in advance. This is done so that the elements do not rub against each other after painting, since after processing a couple of millimeters will be added to the dimensions of the product.

Metal cover regular paint or spray enamel. Wood can also be simply painted, but to preserve the design it is better to use stain and then cover everything with varnish.

But MDF is best covered with veneer or film. To do this yourself you will need coating material, heat and a press. You can use the services of craftsmen, since high-quality work requires special equipment.

The production of the box does not end there, because it needs to be installed. It is carried out in two stages. First you need to assemble the product. Since the door frame was made by hand, there should be no problems with the dimensions. Place all the parts on a horizontal plane, connect and check with the door leaf. If all dimensions match, you can proceed directly to installation.

Installed door frame and door assembly

The door frame is installed with your own hands in the following sequence:

If you carry out the work at each stage in accordance with the rules, a do-it-yourself box will be no worse than a purchased production version.

Almost any major renovation a residential building or apartment cannot be completed without replacing the doors. If new door panels are installed, it would not be a bad idea to change the door frames as well. How to do this with your own hands will be discussed later.

In the event that you purchased door leaves from natural wood, it is also better to choose boxes for their installation from the same material. When purchasing boxed profiled timber, pay attention to the thickness of your walls. This indicator may require the use of a box with additional width. More quality installation additional box additions are possible using a special timber with a longitudinal groove (in the photo it is on the right).

Choosing a box from the array, Special attention Pay attention to the absence of knots and other defects in the parts that may complicate the assembly of the product and the installation of attachments.

After purchasing and delivering the timber, do not rush to use it in your work. Let the tree get used to the conditions in which it will have to “work”, let it reach optimal humidity and temperature.

After that, we will start marking. It goes without saying that installing a frame without the presence of a door leaf for which it is made is nonsense. It is the dimensions of the door that are the starting point in the process of making the base for hanging and fastening it.

Using a tape measure, carefully measure the length, width of the door leaf and its diagonals. The equality of the last values will show the correctness geometric shape products. Typically, the length of the blade is 2000 mm. In this case, the length of the longitudinal bars will be 2006 mm. if there is a threshold and 2023 – if there is no threshold. Increasing the length of the racks is associated with the need to obtain sufficient clearance between the door and flooring, since getting any small elements into the opening can lead to damage to the floor and door leaf.

Similarly, we will mark one or two (threshold) transverse parts of the box. We calculate their width by summing the width of the canvas, the gaps are 3 mm. on each side and two thicknesses of box timber in their thinnest part. With a standard blade of 600 mm, the transverse parts will be equal to 600+6+50=656 mm.

Having completed the markings, we begin sawing the parts. A miter saw or a carpenter's saw with a miter box is suitable for these purposes. If they are not available, a jigsaw will do. In addition, before assembling short parts on each side, it is necessary to saw and chop off small pieces of the protruding part with a chisel and mallet, having previously measured the size of the thickest part of the bars.

After checking that the dimensions of the box parts match the dimensions of the canvas, we proceed to assembly. To do this, we drill holes with a diameter of 4-5 mm in the upper ends of the longitudinal bars. and connect the parts using self-tapping screws 60-70 mm long.

In the last century, the absence of modern electric tool forced construction carpenters to use rather labor-intensive methods of connecting the bars of door frames. It's about about the tenon connection. In this case, both open (a) and closed (b) types of connections were used.

Their manufacture required a lot of time and a full set of carpentry tools. At the same time, the presence of defects sharply reduced the quality of the assembly, which led to various defects that appeared during subsequent operation of the doors.

More quality options tenon joints (trapezoidal or box tenon) are also more complex to manufacture, which required highly qualified workers and was not available in mass construction.

If you buy a door made of MDF, boxed blocks made of the same material or plywood will be sold to match them. In this case, it is better to assemble the box “on the fly”.

To do this, the purchased material is pre-cut on a miter saw. At the same time, pay attention to mutual arrangement vertical bars in a box.

Then the parts are marked taking into account the dimensions of the door leaf and the desired size of the gaps.

To make the connection, the upper butt ends of the box parts are filed at an angle of 45°. Reach high precision possible, using the already mentioned cross-cutting or stationary circular saw With turntable or adjustable stop.

It is important to control the direction of sawing, since the bars will face each other, the cuts must be made taking this into account.

Marking cross beam carry out taking into account miter cuts, stepping back from the end by a few mm.

We also recommend assembling parts prepared in this way using self-tapping screws. Pre-drill holes with a diameter of 4-5 mm at the ends. To avoid mutual sliding of the parts relative to each other, it is necessary to drill perpendicular to the cut edges of the bars.

It is convenient to connect the box using wood screws, having previously laid the parts on a flat surface or aligned the relative positions of the parts with pads of various thicknesses.

An important element of receiving High Quality future doors is correct installation door frame into the opening. For this purpose, the finished frame of three or four beams is carefully aligned using a construction or laser level, plumb. The final position of the box is fixed with wooden wedges.

Then, through the vertical bars, two holes are drilled into the walls of the opening and the entire structure is secured with dowel nails or self-tapping screws, screwed into plastic dowels installed in the holes in the wall.

The gaps formed between the bars of the box and the partition are filled with polyurethane foam, having previously installed 2-3 pieces of boards or bars inside the box. This measure will prevent possible distortion of the structure.

After the foam has hardened, the excess is cut off with a knife and puttied with building mixtures.

Dear readers, if you have any questions, please ask them using the form below. We will be glad to communicate with you;)

Installing a door frame with your own hands is not an easy task, requiring some construction skills and confident work with measuring instruments. Since it is the basis on which the locking structure is built, it is important to approach the process with full responsibility. In this article we will try to describe the main stages of installation and the difficulties that you may encounter along the way.

The door frame can be made from a variety of various materials. The main criteria for selection are the strength and location of the door.

The basis for this material is wood fibers processed in a special way. Fiberboard timber is not at all an example of strength and can only withstand the lightest doors, and also quickly becomes unusable. However, due to its low cost, this material is quite popular, especially for interior openings.

Laminated boxes are most often made from MDF. This material is made from wood chips using urea resins by pressing. high temperature and pressure. It has fairly high strength, low thermal conductivity and noise insulation properties. Its service life depends on the coating, which can be film or veneer.

There are also design features door frames. They can be full and U-shaped. The only difference is whether a threshold is included in the design or instead a ventilation gap is left between the door and the floor. The first type is usually used in toilets and bathrooms, the second - in most passages between living rooms.

Photo from the site krov-yug.biz

So, if you have decided on the type, then you can proceed to the initial stages of its installation. First, measure your doorway with a tape measure. Based on the information received, timber is selected to create the box. This part of the work is the most important and allows you to avoid distortions in the structure and subsequent rework.

There are two widely used methods due to their simplicity. The only difference between them is one thing - the timber is cut at an angle of 45° or 90°. Accordingly, the measurements for each of them also differ.

Vertical bars are measured taking into account the height of the opening, the thickness of the horizontal parts and the threshold (if choosing a rectangular type), as well as the required gaps at the top and bottom (the standard is a distance of 3 mm). Horizontal bars are measured based on their thickness, opening width and gaps. If there is no threshold, then the lower gap should be determined as 1 centimeter so that the door does not touch the floor covering.

In this case, measurements of vertical and horizontal bars are made taking into account the fact that the horizontal bars will lie on the vertical ones. Additionally, you will need to knock down the narthex (the part that is the stopper for closed door) with a chisel or cut with a hacksaw flush with the rest of the timber for a high-quality connection of the vertical and horizontal parts with each other.

With this kind of work, the saying “measure twice, cut once” is more relevant than ever. After taking measurements, cut the timber and fit the individual parts of the box to each other. After this, you can begin fastening it into the opening. Drill the holes into which the screw will be screwed at an angle of 45 degrees (this is necessary for a stronger connection). If you screw them in without going through the drilling stage, the timber may crack and the procedure will have to start all over again.

Photo from the site stroitelstvoiremont.info

If the wall is concrete or brick, then it must be leveled. For this purpose, plaster is used, and in case of significant violations rectangular geometry opening, it is permissible to nail planed boards with subsequent puttying.

Great video on how to make a door frame with your own hands.

Assembly is carried out in several passes

Making and installing a door frame with your own hands is a responsible job that requires care, precision and ability to use tools. Compliance with the installation principles described in the article will allow you to create a high-quality design, and the doors will close without interference or extraneous noise, and will also extend its service life.