For many car owners, the garage is not only a place for storing and repairing them, but also a favorite place for free time. The interior decoration of garages is not so much aesthetic as practical.

First of all, the garage should be dry and warm, especially if there is a basement in which vegetables and canned goods are stored. In addition, high-quality flooring and wall decoration inside the garage greatly influence its cost.

And this is a good reason to think about how to decorate the inside of the garage.

Before finishing the walls and floors, we pay special attention to the garage ceiling. It is from it that water often drips after a good rain.

In order to avoid this, and not waste future finishing, you need to take care of high-quality waterproofing.

So:

If the ceiling needs to be insulated, it is better to choose any frame method finishing. After all, it is very convenient to install insulation into the cells of the sheathing.

Usually in a garage both the ceiling and walls are sheathed the same way. Therefore, we will tell you how and what to decorate the inside of the garage in the next section of our article.

Many garage owners prefer to make do with only rough wall finishing. Most often, this is plastering.

If you have the skills to do this kind of work, everything is much easier. All that remains is to purchase dry plaster mixture and the necessary tools.

Note! To decorate any unheated room, including a garage, purchase cement-based plaster. Gypsum mixtures, used in residential premises, are not suitable for this purpose.

So:

Decorating the walls of the garage inside can be done facade plaster. The fillers for such solutions are crumbs from various types of stone: quartz, sandstone, granite, marble.

It is usually sold separately and is added only to the batch that is being made for the finishing layer.

The procedure for performing this work will be the same for walls and ceilings, and there is only one selection criterion - the surfaces need to be insulated. And it is not at all necessary to choose the same material for covering the ceiling and walls.

So:

Not all people look at decorating a garage only with practical side. Some people also think about design.

And here’s a relevant example: on the front wall of the garage there is a panel of ceramic tiles. We advise you to lead by example!

If your garage does not have a crawl space or crawl space, the base floor will be compacted soil. In this case, task number one is to perform concrete screed.

So:

As you can see, nothing is impossible, and decorating the inside of a garage with your own hands is within the capabilities of anyone. And we, in turn, really hope that we were able to help you understand this issue. We wish you success in achieving your goal!

For many car owners, the garage is not only a place to “reside” the vehicle, but also a place for repairs, storage, painting and plumbing work, etc. In an effort to use the room as more than just a box of metal, we think about its finishing. And here the priority is not only high quality materials, but also a low cost of work. To this end, we will look in detail at how to complete the finishing on your own, so that anyone can handle the technology, and the result will not disappoint.

Let's look at the conditions under which a garage requires interior finishing, or at least cosmetic repairs.

Exterior decoration of the garage is necessary:

The interior decoration of the garage includes the cladding of all surfaces of the room and the installation of floors. Special attention pay attention to finishing materials. Most often, the garage is subjected to intensive use, chemical and mechanical stress. Therefore, to preserve structures and ensure fire safety, the following requirements are imposed on materials:

There are a sufficient number of options for finishing the walls, ceilings and floors of the garage to suit every taste and budget. Here everyone decides for themselves, comparing their desires and capabilities. However, the choice depends not only on the personal preferences of the owner, but also on the material of the enclosing structures themselves.

Walls and ceilings:

Minus finishing material is the complexity of plastering work, the need for the necessary skills and the presence of construction dirt during work.

After the plaster has dried, it is recommended to putty the ceiling and walls before painting to save paint and varnish materials and smoother application. The putty is applied in 1–2 layers to the surface treated with a primer. Application thickness - up to 3 mm. It is better to carry out the work using a façade mixture or a cement binder.

If putty is not at all part of your plans, painting can also be done on a plastered surface. But be sure to coat the surface with a primer before painting. deep penetration, which will not allow the paint to be absorbed into the concrete.

Advice: Plastering should be carried out in the warm season.

Several types of compositions are suitable for painting: epoxy or polyurethane based paints, facade paints.

Plastered and painted walls and ceiling

However, there are some limitations. They cover brick, concrete or aerated concrete surfaces, and thin, light walls will not withstand the considerable weight of the tiles and a layer of adhesive. In this case, minimal vertical deviations are allowed. Obviously, finishing walls and floors with tiles is an expensive pleasure, and time-consuming.

The walls and floor of the garage are covered with ceramic tiles

The walls and ceiling are lined with PVC panels of the same color

Chipboard cladding

GCR with coloring

Painted concrete floor

Ideal self-leveling floor surface

The entire interior area of the garage is lined with wooden boards

Summing up and analyzing the options in terms of practicality, durability, resistance to damage, as cladding interior walls garage, we advise you to opt for concrete floors and plaster. This option is appropriate if the walls are made of brick, concrete or aerated concrete. If the work is performed with high quality, you will receive decent result with minimal labor and cost. As for walls made of metal profiles, they can be sheathed PVC facade panels.

Anyone can calculate the amount of plaster mixture. Let's say you know the area of the garage walls without taking into account the openings S st in m 2. The main thing is to determine the average layer thickness t sl. To do this, measure the deviation in several places with a two-meter level and calculate its average value.

Consumption cement plaster manufacturers indicate on the packaging. On average, this value is 8 kg per 1 m2 with a layer thickness of 10 mm.

Required amount of mixture: N cm = S st x t sl x 8 kg.

Most often, dry plaster mixture is supplied in bags weighing 30 kg. Divide the resulting value N cm by 30 and round the number up. You receive the number of bags needed to plaster the walls.

The required amount of paint N cr also depends on the consumption indicated by the manufacturer on the packaging.

Let's calculate the amount of material in a garage with walls 4.5 m and 3.5 m long and a room height of 2.5 m.

The area of the garage walls is: (4.5 + 3.5) x 2.5 = 40 m 2. Having measured the deviation from the vertical, we obtained the following values: 3.5 cm, 2.5 cm, 1.5 cm, 3 cm.

Average layer thickness: t sl =(3.5+2.5+1.5+3)/4=2.6 cm, rounded to 3 cm (0.03 m).

Amount of mixture: N cm =40x3x8 =960 kg. Number of bags: 960/30=32 pcs.

Epoxy paints for painting walls in 2 layers have a consumption of about 400 g per 1 m2 (0.4 kg/m2).

Amount of paint: N cr = 40x0.4 = 16 kg. Packaging of paints from 5 kg per container and above.

To calculate cement and sand when installing floors, determine the thickness of the required screed. Depending on the base, the presence or absence of insulation, it can vary from 3 cm to 10 cm. The volume of the screed is calculated by multiplying the thickness by the floor area. ¼ of the resulting volume is M400 cement and ¾ of the volume is fine sand. A desirable condition is floor reinforcement. For this we use a wire mesh Ø5 mm with cells 10x10 cm.

The floor area of our garage is determined as: S=4.5x3.5=15.75 m2.

Volume of gravel V gr and sand V pes for a pillow, thickness 20 cm (0.1 m +0.1 m): V gr = 15.75x0.1x1.1 = 1.7 m 3, V pes1 = 15.75x0, 1x1.1=1.7 m3, where 1.1 is the compaction coefficient.

Let's take the screed thickness to be 5 cm. Screed volume: V st =0.05x15.75=0.79 m3. Therefore, the volume of sand: V pes2 = ¾ x 0.79 = 0.6 m 3, the volume of cement: V cem = ¼ x 0.79 = 0.2 m 3. Based medium density cement 1300 kg/m 3 we obtain the required weight of cement: N cement = 0.2X1300 = 260 kg.

Amount of paint: Ncr = 15.75x0.4 = 6.3 kg with a material consumption of 400 g per 1 m 2.

The process of installing a concrete garage floor depends on the substrate. If there is an existing concrete slab, then to fill the finishing screed you only need to clean it of dust.

Tip: If water constantly accumulates in the garage, make the floor slope 3%.

When pouring a floor over the ground:

Advice: Pouring concrete should be done without long breaks and in the warm season.

Plaster work starts from the ceiling and ends with the walls.

There are many types of garage façade finishes. The most popular of them:

Unstitching. This is the easiest and most inexpensive way to bring your garage into decent shape. The color of the grout mixture can be used darker or lighter than the brick itself, which will add contrast to the walls. In this case, greater strength of the masonry is achieved.

The garage walls are made of colored bricks with beige grout

Plaster. Plastering is inexpensive, but, as with interior decoration, it is a rather long and dirty process. If the quality of the interior finishing is hidden from prying eyes, then plastering the exterior will require experience, skill and patience.

In this case, the walls can be insulated. This facade is called “wet”. The insulation is glued to the wall, then a fiberglass reinforcing mesh is attached to the polymer-cement mortar. Facade or decorative plaster is applied to the surface, followed by painting.

The walls are plastered and painted

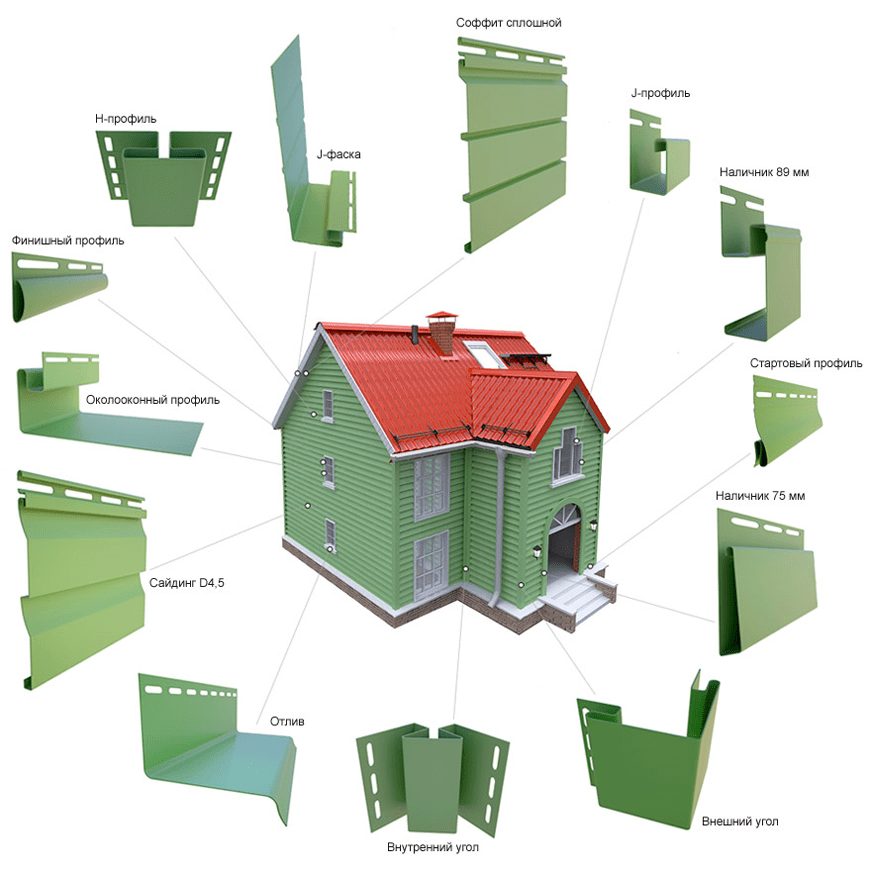

Siding. You can insulate and decorate a garage with the most inexpensive and versatile material - vinyl siding. It does not crack, does not rot, is not subject to deformation in dry and wet weather, has a rich range of colors and looks neat. You need to be meticulous in its installation, but you won’t need any special abilities.

Covering with horizontal siding panels

Wooden lining. For lovers environmental materials the facade can be covered with wooden clapboard. The advantages of this type of finishing are cozy warm look, variety of textures and simple installation process. But the tree needs constant antiseptic and fire retardant treatment, and given the uneconomical nature of this material, such a finish will not be affordable for everyone.

Wooden clapboard garage

Natural or fake diamond. Luxury finishing - lining the garage with natural or artificial stone. The facade looks expensive, beautiful, and is not afraid of low and high temperatures and moisture. However, the price is too steep.

Garage walls made of natural stone

Sandwich panels. Sheathing with sandwich panels is a convenient option for performing two tasks at once: insulation and finishing of the facade. But due to the significant weight of the panels, not every foundation and wall can withstand such a load. The material finds its best use as independent enclosing structures.

Garage walls made of sandwich panels with contrasting profiles

Based on the most important indicators of efficiency and ease of installation for car enthusiasts, we will describe in more detail covering a garage with siding with insulation, as the simplest and most inexpensive way finishing.

The essence of the method is to construct a wooden or metal frame, in the cells of which insulation is placed. A vapor barrier must be installed on top of the insulation. Siding panels are mounted on sheathing built on top of the previous frame.

Consequently, when finishing a facade without insulation, only the sheathing is installed.

The thickness of the insulation, which is suitable for polystyrene foam or polystyrene foam, should be taken within 5 cm. Accordingly, the cross-section of the sheathing strips should be at least 5 cm.

The amount of siding needed is calculated by dividing the area of all walls, minus openings, by the area of one panel, or by dividing the height of the wall by the height of the siding element.

Standard panel length vinyl siding within 2.5–4 m, and the width is 20–30 cm, but in the calculation it is worth using usable area element.

The lathing is calculated provided that the distance between the guides is 0.3–0.5 m.

You will need:

For example, consider a garage with dimensions of 4x5 m in plan. Building height (H) - 2.8 m, gate (hxl) - 2.7x2.5 m.

Garage perimeter: P=(4+5)x2=18 m.

Wall area excluding openings: S st =РхН-hxl=18х2.8–2.7х2.5=43.65m2.

Length of the sheathing in increments of 0.5 m under the insulation: L arr =P/0.5xH+H/0.5xP=18/0.5x2.8+2.8/0.5x18=126 m. Number of stands instead of the sheathing: N under =3xS st =3*43.65=131 pcs.

Volume of a mineral wool slab 5 cm thick: V ut = 43.65 * 0.05 = 2.18 m 3.

Vapor barrier: S steam = S st = 43.65 m 2.

When facing with siding, we use panels 4 m long and a useful height of 0.19 m. To cover walls 5 m long, we cut additional meter-long elements from the main profile.

Required number of whole panels: N 4 = 4x2.8/0.19 = 59 pcs.

Number of shortened meter elements: N 1 = 2x2.8/0.19 = 29.4 pcs.

Panels 4 m long for cutting meter pieces: N 4/1 = 29.4/4 = 7.4 pcs.

Total number of four-meter siding elements: N pan =59+7.4+7%≈71 pcs., where 7% is a reserve for waste, etc.

Quantity of H-profile: N H-pr = 2 pcs.

Starting and finishing panels: N st =N fin =P/4=18/4=4.5≈5 pcs.

Number of corner panels: N corner =2.8x4/4=2.8≈3 pcs.

Quantity of J-profile: N J-pr =(2.7x2+2.5)/4=1.9≈2 pcs.

Self-tapping screws for fastening siding: N itself = 20x43.65 = 873 pcs.

Setting up your favorite garage can take a huge amount of money and time, because you can’t get by with just one specialist, and you need control over everything. The question arises: is the finishing worth it? utility room financial and labor costs? Our answer: it’s definitely worth it, if you approach it wisely and do the full range of work yourself. By carrying out work conscientiously according to the recommended technology, you will not only save money, but will create a cozy space according to at will and the project, while gaining invaluable experience and recognition from households and neighbors.

Hello! My name is Kireeva Ekaterina. I am 29 years old. Graduated from the Construction Institute as part of State University Togliatti in 2008 in the direction of "Industrial and civil construction". She is well acquainted with construction and production. Thanks to this, articles on construction topics are very close to me.

Every car owner spends a significant part of his time in the garage, and the question of comfortable time spent in in this case becomes relevant. You can make your garage more comfortable by decorating the interior walls. Read an overview of the characteristics of the species inspection hole in the garage .

Due to the specifics of the functional use of the room, the finishing material for lining the walls of the garage from the inside must have a number of certain qualities and performance properties:

You can sheathe the walls in the garage from the inside with the following materials:

Each of the listed materials has certain advantages and disadvantages.

Plastering walls was previously the most popular way to decorate garage walls from the inside. Today, plastering is not so often used, but it is the most in an accessible way wall decoration at a price.

Plasterboard is in demand as a finishing material for walls, and garages are no exception.

Advantages of using plasterboard sheet:

Advantages of using plastic panels:

Advantages of using OSB boards:

Unheated garages are not uncommon, and when decorating the interior walls of the garage, it is recommended to use all possible ways to maintain positive air temperature inside the garage for as long as possible. One of these methods is to use heat-insulating material for wall cladding, under the decorative and finishing layer.

The most popular and affordable thermal insulation materials suitable for cladding indoor garage walls:

To secure the thermal insulation material to the surface of the walls, you will need to pre-mount the lathing. The sheathing can be made of either wooden slats or metal profile. Keep in mind that when using wooden slats, they must be treated with an antiseptic compound to prevent the formation of mold. In addition, before installing the sheathing, the walls must be waterproofed. The thermal insulation is placed in the space between the laths, the insulation is attached, as a rule, to an adhesive base and mechanically using self-tapping screws with a wide head.

The use of thermal insulation material in the process of wall cladding will significantly reduce heat losses.

One of the modern finishing materials that is optimal for finishing the walls of an unheated garage are sandwich panels, which are structurally a multilayer sheet consisting of two outer layers, which can be made of PVC, moisture-resistant plywood, wood-polymer materials and an inner thermal insulation layer.

A garage sheathed on the inside with wooden clapboard looks very impressive, but keep in mind that such finishing material requires constant maintenance, that is, it is necessary to regularly treat walls lined with wooden clapboard every two or three years with antiseptic and fire-resistant penetrating primers.

The use of plastic panels for interior decoration of garage walls is very popular, since plastic panels are characterized by a long service life and ease of installation (a garage can be sheathed within one day). Range of plastic panels on the market building materials, will allow you to choose finishing materials to suit every taste.

When choosing a finishing material, you should focus, first of all, on design features garage (area of the garage, is there heating), in addition, it is worth taking into account such a nuance as the garage’s susceptibility to flooding.

Many motorists think about the appearance of a garage for storing cars. Some people like the regular one metal box, while others want to make the room more comfortable and comfortable. It is recommended that you familiarize yourself with how the interior of a garage is finished so that you can arrange everything yourself.

Before you start finishing, you will have to familiarize yourself with what it includes. Finishing work, based on the location where it is carried out, is divided into two main categories.

Many people are interested in how to sheathe the walls of a car garage from the outside. External finishing is taken more seriously than internal finishing, since the safety of the structure depends on the quality of the work performed. If you use low-quality material for cladding, it will quickly deteriorate under the influence of temperature changes, sun rays and atmospheric precipitation.

Before performing exterior finishing of garage facades, you need to familiarize yourself with the nuances of choosing the appropriate material. Experts advise buying products that have the following properties:

Experienced builders advise purchasing materials that are used only for exterior work. Often, wooden siding, lining or special moisture-resistant plaster are purchased for this purpose.

A car garage should not only be safe, but also comfortable, so that a person can stay in it longer. It is for this purpose that interior finishing work is carried out, which will make the room for long-term car storage more attractive.

The finishing that is carried out inside must be done using the most suitable materials. Therefore, when choosing them, pay attention to the fact that they are:

Exist various options materials that are used for interior wall decoration with your own hands. Therefore, they choose in advance what to paint the walls with, and also determine what is suitable for their cladding.

Many people prefer to decorate their walls with plaster, as it can last for several decades. Its advantages include heat resistance and low cost.

Before applying the plaster mixture to the surface, you need to check the temperature inside the garage. It should not be lower than five degrees, since at low temperatures the plaster adheres less well to the wall.

Wall panels made of plastic are considered universal, as they are used for external and internal finishing work. The advantages of PVC products include a high level of protection against mechanical damage, as well as ease of maintenance and installation. Such panels can be installed in two ways: on a wooden frame or directly to the wall.

To create an attractive interior inside the garage, its walls are tiled. When arranging a garage, some people use tiles, as they cope with high humidity and temperature changes. The tiles are also easy to clean from dirt and do not become deformed. Its only drawback is considered to be low strength.

Builders recommend using plywood only for interior decoration of garages, since the material is poorly protected from high humidity. To increase its moisture resistance, you will have to pre-treat the plywood with special protective agents.

Among the most famous facing materials is wood. For cladding the walls in the garage, choose wood that does not contain toxic substances.

Before use wooden materials treated with fire-fighting agents to increase heat resistance and an antifungal solution.

Some use it for cladding plasterboard systems with increased fire resistance and moisture resistance. Among the advantages of drywall are its low cost, ease of installation, flexibility and light weight. The main disadvantage of the material is considered to be its poor impact resistance, due to which the plasterboard surface is subject to mechanical damage.

When covering the walls of a car garage, some people use clapboards made of plastic or wood. The pros of this facing material include:

The metal profile is considered durable and strong. He also copes with mechanical influences and temperature changes. However, despite all the listed advantages, builders do not advise using the material in high humidity, as it quickly rusts.

This good material, which is often used for internal lining walls in the garage. It, like metal, is susceptible to corrosion and therefore cannot be used at high humidity levels.

When decorating the interior of a garage, not only the walls are treated, but also the floor. Various facing materials are also used to finish the floor surface.

Wood is often used as flooring for garages, as it has a number of advantages. These include:

Disadvantages include rotting due to moisture and susceptibility to insect attack.

Often in garages they make a concrete floor surface, which has the following advantages:

Among the disadvantages of concrete flooring is the difficulty of creating a floor. It is better to entrust such work to professionals who have repeatedly made concrete floors in car garages.

Asphalt chips are used to finish the area that surrounds the garage. Some motorists use it to finish the flooring inside the garage. This material is resistant to cold and moisture, and also provides a high level of adhesion of car tires to the surface.

Not a bad replacement asphalt crumbs consider ceramic tiles, which is resistant to temperature changes and humidity. Ceramic products are divided into five classes, differing in their quality. For garages, class 5 tiles are used, as they are the most wear-resistant.

Before you make a self-leveling floor in a car garage, you need to figure out what you can fill it with. To do this you can use:

Before you start finishing work inside the garage, you need to understand the peculiarities of working in rooms with and without heating.

It is no secret that at very low temperatures mold and fungi form on surfaces. They interfere with the work and therefore you will have to clear the walls and floor of them in advance. Then you will have to raise the temperature in the room to at least 10-15 degrees, since finishing is contraindicated at low temperatures.

If in the future the garage will not be heated, materials with resistance to high humidity and low temperature. In this case experienced builders It is recommended to use PVC panels for the walls and asphalt for the floor.

Lining your garage is very important. Cladding is done inside and outside. Of course, it performs several functions at once. The emphasis is on the following:

Today we will take a closer look at the exterior wall decoration. Let's find out how to cover the outside of a garage, what materials are most practical and economical. Let's look at the process of covering walls with siding and find out the features of the technology. All useful information, algorithms and tips will help you then carry out all the work yourself and achieve best result. Then the garage wall cladding will serve you for many years and will successfully perform all its functions.

Quite used now wide range building materials for cladding exterior garage walls. We will focus on the main ones and pay attention to them key characteristics. The greatest demand is for siding and plaster, as well as lining and artificial stone, and blockhouse. Of course, some garage workers choose brick cladding.

The technology is widespread wet facade" This is not just plastering walls. The process will be a little more complicated.

From a technological point of view, the work is somewhat complex, but with certain skills it can be done easily. It is important to follow the sequence, do everything carefully, and monitor the quality of the solutions. Then this finish will last a relatively long time. The basic advantages of the method are the reliability and strength of the walls, the effect of thermal insulation, and efficiency. True, in order to ensure decent quality of such a coating, you will have to additionally level the walls before carrying out the work.

Siding is extremely popular. You can choose metal or cement, wood or vinyl siding. Everything will depend on the personal preferences of the car enthusiast and budget capabilities. Vinyl siding is widely used, which attracts with its optimal combination of reasonable cost and good technical characteristics. Let's note its advantages.

Some garage workers opt for wood siding. It certainly requires additional treatment with fire retardants, and is also quite expensive.

Cement siding is not very practical due to a significant drawback - heavy weight. Popular metal siding. It is very durable, it is not afraid of mold and mildew, and temperature changes. But you will have to take additional care to protect the material from corrosion. It is necessary to use special self-tapping screws with rubberized heads during the installation process.

An original option for cladding the outside walls of a garage is a blockhouse. It is most suitable for those whose house nearby is also decorated with this material. Then a residential building and a garage will make an excellent architectural ensemble. The blockhouse looks elegant and visually imitates log wall. The material is divided into classes. For a garage, you should choose class A coating, which is most suitable in terms of quality and price.

An interesting solution is to use wooden lining for lining the garage walls. It is produced from conifers, deciduous trees. This material is distinguished by its environmental friendliness and safety, but requires additional processing. Here you need to use fire retardants to increase the level of fire safety. Of course, the ease of installation of the lining is also attractive: the elements of the material are immediately equipped with a special locking system based on the tongue-and-groove principle. This is very convenient in the process of fixing the wall covering layer.

The lining is produced in several classes. The highest quality ones have the highest price. You can opt for the optimal option: class A lining has completely decent characteristics And average cost. It is just perfect for covering a garage.

Some garage workers choose stone for wall cladding. This material allows you to create a memorable design and turn the building into a work of art. Of course, there are some nuances. During the installation process, dealing with stone is not so easy. It is advisable to have at least minimal builder skills, since the process is labor-intensive: it is important to apply it correctly adhesive composition, do everything as carefully and competently as possible so that the coating is securely fixed.

You also need to choose, artificial or a natural stone use. Natural material has better performance characteristics, but it weighs much more and is more expensive. This will require a significant budget, and there will also be a serious load on the walls.

Covering a garage with siding is the optimal solution. Let's take a closer look at the process of wall cladding and find out how to make the coating as reliable, durable and aesthetic as possible.

Of course, you will need the siding itself. You can choose vinyl. Also, immediately think about how you will install the panels. Because the garage space most often there is no heating, the best solution in this case, the walls are faced from the outside using a ventilated façade system. Then you will simultaneously carry out thermal insulation. Thermal insulation material is simply placed into the sheathing cells during the installation of a ventilated facade with siding. Internal area will remain free from the insulation layer.

It is important to decide on the type of siding panels. It determines what configuration of your ventilated façade you will have and what specific structural elements you will need.

Siding can be metal and vinyl, composite and plastic, cement. A wide range of color solutions. The cost largely depends on the raw materials from which the siding is made. There are no fundamental differences in the installation of elements, but there may be a slight difference in features lock connection. Choose the most suitable option, taking into account individual preferences and planned budget, but also do not forget about the technical characteristics. Vinyl siding remains the most practical.

We are considering the option of covering the walls with siding using the type of ventilated facade, which immediately ensures insulation of the structure. Let's look at the features of the frame in our case.

You can make a ventilated facade on wood or metal frame. If you do insulation, then you should give preference combined option. This is what experts and experienced garage workers recommend. Then the lower sheathing is made from bars with parameters 30 by 30 mm, but the upper sheathing must be made from a profile. Think about which option suits you best, and pay attention to the cladding scheme with an insulating layer.

Let's find out why install two battens. The fact is that decorative and thermal insulation materials will differ in size. At the same time, during the installation process, special convenience is created by following the step frame belts. It is also important to guarantee a certain thickness of the sheathing so that there is a gap between the cladding and the insulation. It is this distance between the layers, which should be approximately 3-4 cm, that is necessary to create a ventilated façade.

Sometimes garage workers do without the bottom sheathing. They fix the insulation by attaching it to the walls of the garage with dowels, glue mixture. In this case, an indent from the base is still needed. Then it will have to be done using direct hangers. Remember that in this case you will need to glue all the joints between the insulation boards with special insulating tape.

The best solution is to install a lathing under the thermal insulation layer. A step is taken between the profile and the bars, which should be 1 cm less than the width of the slab itself. Then thermal insulation material will fit well into the cell, it will be much easier to fix it with glue. You don't even need to hold the slab while the glue dries.

Expanded polystyrene and mineral wool are suitable as insulation. Be sure to pay attention to fire safety: you need non-flammable materials.

The best option for lathing is a metal profile.

You will need a set of tools: a screwdriver and a hammer drill, a marking cord and a building level, a screwdriver with a hammer, and electric jigsaw or metal scissors.

Let's consider the algorithm for installing siding on the outside of garage walls.

To accurately navigate all the intricacies, it is worth watching the video.

Now you can find out even more useful information about siding. It is this material that is increasingly popular as the main exterior cladding of garage walls.

This video tells in detail about siding, its main technical characteristics, and advantages.

Have you finally decided to use siding to cover the walls of your garage? This a good choice. But you will need to understand in more detail how best to install a metal profile under the siding. The following video will help you.

Watch the video carefully. It clearly presents instructions for installing a metal profile under siding. By following the recommendations, you will achieve reliability and durability of the cladding.