- a set of piles of various types, on which the building rests. Piles protrude above ground level, therefore an open space is formed under the building.

There are several ways to equip a pile base:

Concreting is carried out by pouring the concrete mixture into the formwork. A shallow trench is dug first.

It is possible to pour a reinforced concrete monolithic tape into the prepared trench, and then lay a brick on it (). This method is good because it does not require strengthening the formwork above ground level.

A fence is a stone or brick jumper, which is mounted between piles. This is usually done in the case of the construction of small light buildings.

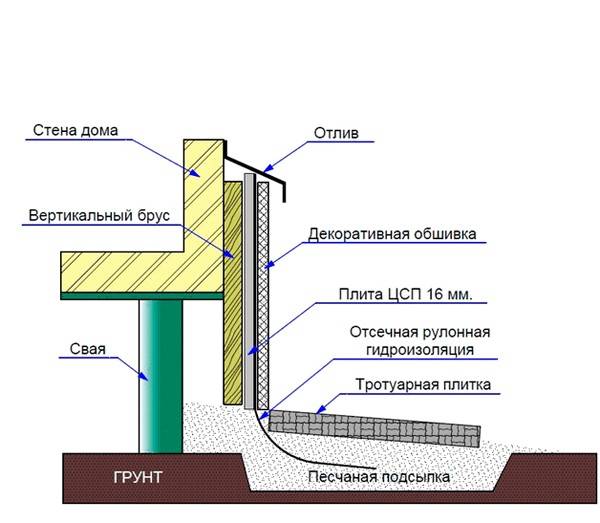

Hinged panels are mounted on a crate made of boards or metal. They are often used as a decorative finish () on brickwork or concrete.

If you are wondering how to make a plinth on a screw pile foundation quickly and inexpensively, pay attention to the advantages of a hinged structure ():

If you are wondering how to make a plinth on a screw pile foundation quickly and inexpensively, pay attention to the advantages of a hinged structure ():

I would especially like to note the combined panels - three-layer structures made of OSB boards, polyurethane foam insulation and decorative stone.

The latter serves as a decorative finish. The color range of the outer layer is quite extensive.

The installation of the basement of the screw foundation begins with the waterproofing of the piles and the grillage (). It is not recommended to skip this stage, regardless of what material the foundation elements are made of.

The installation of the basement of the screw foundation begins with the waterproofing of the piles and the grillage (). It is not recommended to skip this stage, regardless of what material the foundation elements are made of.

Metal must be protected from corrosion, wood from decay. Appropriate mastics and antiseptics are used for processing.

At the final stage, the corners are reduced, additional elements, ebbs, drips and junctions are mounted.

Video about finishing the basement of a house on screw piles.