One of the ways to finish the plinth is to use facing stone. This material is easy to use and looks great. From the article you will receive information about its properties and features of choice. You will also learn how exactly the plinth is clad with natural stone.

Natural stone for home cladding has both pros and cons. The main advantage of this material is its environmental friendliness and safety for health. In addition, it is very durable and ready for any load. These properties are explained by its structure.

The stone for finishing the plinth does not require complex maintenance. It can be wiped with a normal damp cloth. The use of chemical cleaners is not recommended.

The advantages of natural material include:

The only negative natural stone is its price. It is much more expensive than other materials used for basement decoration. In addition, on initial stage it is difficult to make calculations and often more material is purchased than needed. Of course, you can veneer the basement level of the house with an artificial analogue. Outwardly, it almost does not differ from natural, but it costs less. The technology of their installation is also almost the same.

Many note that natural material has another drawback - irregular shape. This complicates the construction of the structure, since a lot of time is spent on trimming. This is especially true for rubble stone.

Finishing the basement can be done using:

Natural material is characterized by a wide variety of shapes, colors and textures.

Consider the properties of the most popular stones in more detail.

Sometimes marble is chosen as the stone for finishing the basement. Actually, use this decorative material for external works undesirable. In severe weather conditions, it can be deformed, which will spoil the whole look of the house. If you want to achieve an interesting result, consider using rubble or a combination of materials.

The first thing you need to consider before buying stone for a plinth is the estimated cost. If you don't have a big budget, then best solution become sandstone and shell rock. To economical options also includes quartzite. If a sufficient amount is laid down for the decoration, you can choose something more attractive, for example, granite or rubble stone.

Butovy stone.

Then you should think about the color scheme. The basement finishing material should always be selected for the design of the entire structure. In some cases, you can choose a stone that is two tones darker than the house. This could be an interesting design decision.

When buying, be sure to ask the seller for certificates of material safety and its origin.

The technology for installing the plates is not entirely simple, but after carefully studying the instructions, you can do the work yourself.

Plinth lining process.

Laying can only be carried out on prepared walls. First, a blind area must be made around the perimeter of the entire house. It is a small protrusion that will protect the base from the damaging effects of moisture.

Next, it is necessary to process the surface of the base so that the facing material can better attach to it. Make sure that there are no potholes and cement buildup on it. Now it's time for the primer. Large-fraction concrete contact is well suited.

If you decide to insulate the building, it is better to use expanded polystyrene. It is convenient in that it simplifies the facing process a little - it will not be necessary to carry out a primer. Attach the panels around the entire plinth using fixing dowels. Place a metal mesh on it.

The last item is skipped if the work is carried out using rubble stone.

Suitable for regular concrete. It is recommended to add a plasticizer to it. This will allow you to more tightly connect the base material and natural stone.

Mixing the solution.

Laying is carried out from left to right and from bottom to top - this is much more convenient. Facing material must be selected according to size, lubricated with a solution and attached to the wall. In fact, you need to assemble a mosaic, choosing the most suitable and beautiful pieces. In extreme cases, you can cut some pieces with a grinder to get the desired shape. Most likely, you will have to resort to this at the corners of the building.

Sometimes the material needs to be pre-washed. So, rubble stone is often contaminated with dust and earth, which does not allow attaching it to walls. Laying will be much easier if you thoroughly wash and dry each stone.

When you're done laying out the basement decorative rock on one wall, grout the seams immediately. This must be done before the solution hardens. Then you can move on to another wall. The bottom and top rows need to be aligned horizontally. Upon completion of work top line plinth is cut.

Rubble stone suggests an additional way of laying. The technology in this case is somewhat simpler than described above.

If you work intermittently, cover the concrete with a tarp to keep the rubble layer from drying out.

It remains to additionally protect the basement material from moisture. Under its influence, natural (including rubble) stone will gradually collapse: first, microcracks will appear, and then its peeling will begin. To prevent this, it is worth covering the finished surface of the base with a colorless moisture-resistant varnish.

Thus, stone plinth cladding is one of the most popular finishing methods. If you have a certain building experience, laying the plates can be done by hand. The final result will definitely please you. Relatively uncomplicated installation, durability, excellent decorative effect and weather resistance - and this is not all the wonderful properties that this plinth material has.

AT recent times, stone for plinth cladding is gaining more and more popularity among finishing materials. Occupying the mid-price segment of the market, given material outperforms non-natural finishes in key technical and design criteria.

The basement of the house, or ground floor is a fundamental structure, the foundation of a structure that performs a number of functions. The basement takes on the entire complex of loads, starting from the mass of the whole house, soil and storm water, and ending with the processes of foundation settlement over time.

Finishing, or rather the lining of the basement, is an action to improve the functionality of the lower, often technical floor and also includes work on architectural design, as part of bringing the project to a common artistic denominator - the concept.

Depending on the state of the budget, various groups of materials are used to finish the basement, such as plastic (siding, etc.), metallic profile, cement plaster, sand-cement products "under-stone", and, as the most expedient (but not the cheapest), natural remedy - natural stone and products from it.

Pankamen is engaged in the production of stone plinth tiles and supplies to construction market a wide range of cladding materials, including many types of tiles and stone for plinth finishing, as well as products for laying and processing them.

The natural stone used in the lining of the plinth is chosen taking into account its shape, texture of the front surface, color, and geological formation.

As a plinth stone, Pankamen offers wide range options to choose from among the main categories.

Finishing the plinth with flagstone is a common method of facade cladding, due to the low price of this stone, its natural origin and ubiquitous mining.

Flagstone sits well on stone glue, resistant to aggressive environments, moisture, and radiation. As a result of finishing, a unique picture is obtained, which has a unique pattern of seams and combinations of natural shades.

Price "Plytnyak" of the company Pankamen illustrates the variety of types of facing flagstone for finishing plinths.

View catalog:

A stone with a relief is called wild front surface, arbitrary edges, indefinite shape. It is used in plinth cladding both with flagstone and without it.

wild stone provides experienced designer sufficient field for the flight of thought, and other projects using this natural facing material simply captivate with their primitive charm.

Pankamen offers wild stone for cladding at affordable, sometimes even low prices.

View catalog:

Facing tumbled stone, otherwise, tumbling - it is limestone, or wild stone, processed by turning in metal drums with the addition of water. In addition to polishing the surface, sharp edges and corners are smoothed during processing, resulting in a stone that is indistinguishable from the sea.

The tumbling in the plinth finish is used to imitate the fact that the foundation is built from boulders.

Pankamen' tumbling shops produce a wide range of tumbling for plinth cladding. The price list includes many types, dividing them by size, shade, and price.

To implement plinth finishing projects, taking into account the geometry of the seams, the symmetry of the cladding elements, or the analogy with brickwork, special stone tiles are used for plinth cladding.

Feature tiles "Rock" - chipped around the perimeter.

The product catalog contains: photos of the "Rock" tile, characteristics and retail prices in a warehouse in Moscow. The price includes packing on a pallet and loading.

View catalog:

Unlike "Rocks", flagstone tiles have a regular cut along the perimeter.

Facing tiles and stone for finishing the plinth are made mainly of sandstone - the most common rock. Sandstone meets all the requirements for building material in terms of physical and technical characteristics, artistic value, and environmental friendliness.

| Articles |

Facing the basement with natural stone is considered the most popular. All this for the reason that the material has a very attractive appearance and excellent technical characteristics.

Facing the basement of a house with natural stone can be done using:

Let's take a closer look:

Advice. In order for the shell rock to serve as a finish for a long time, its surface must be covered with a protective layer. Use a special primer or a simple varnish for this.

Advice. Facing the basement with wild stone can also be performed by other breeds that are of natural origin. The most important thing is that the material be extracted in those regions that, in terms of climate, will be similar to the climate of the region in which the house is being built.

Advice. In the decoration of the house, marble slabs are very often used, only in outdoor decoration it is not recommended to use such material, since in some regions its structure may be subject to deformation and for this reason the external design of the building will be damaged.

The first thing you need to focus on is the budget for finishing. If it is not too large, then you can use shell rock or sandstone. Quartzite also belongs to the economy category. If the amount allows, then you can choose a more attractive granite.

Further:

Advice. When choosing a natural stone, you must definitely ask the seller for certification documents that indicate that the stone does not emit radiation and is of natural origin.

For facing the basement of a house, it has the main property - environmental friendliness. It will not harm human health and the environment.

It is very durable and reliable. On its surface, it can withstand almost any load. All this is due to a very dense structure.

Features and Benefits:

Advice. To finish the plinth, in addition to natural stone, you can use artificial, which appearance is no different from natural, only costs several times lower.

Natural stone has several types of surfaces that have an original appearance and are all popular.

Surface:

Advice. When choosing a natural stone surface, it is worth considering how easy and fast it will be cleaned. If there are a lot of different recesses on the surface, and the color of the material is light, then it is better not to use it for facing the base.

Facing the basement of the facade with natural stone can be combined with any other finishing material on the surface of the walls.

The most common option is plastered walls with natural stone on the plinth. Very often you can find natural agglomerate on the plinth, and artificial stone on the walls.

So:

Advice. Plastic lining for finishing a building using natural stone on the basement, it is not recommended to use it, since the house will not look aesthetically pleasing.

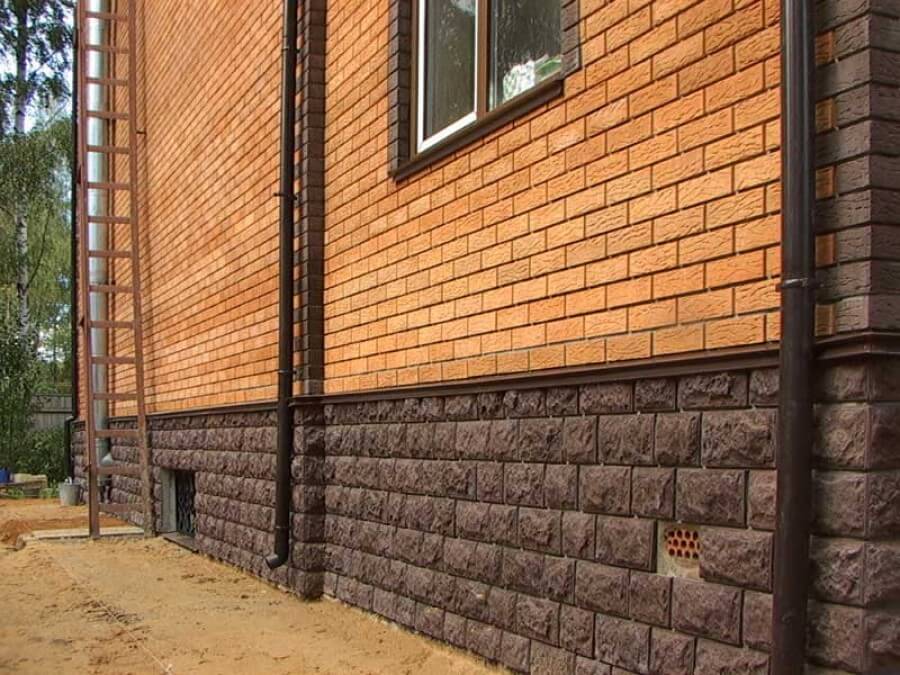

The photo shows various options decoration of the building with natural stone on the plinth.

The plinth, as a rule, is built of red refractory bricks. It has excellent strength and can withstand heavy loads.

And natural for the base has a very large weight and for other surfaces it will be mandatory to strengthen them.

The next step is to level the surface:

Advice. If the brickwork is even and there are no deposits on the surface concrete mortar, then you do not need to level the surface either.

Advice. To make the solution stronger and with a denser structure, it is necessary to use proportions of 1 to 2 or 1 to 1.

To apply the solution to the surface, a spatula and trowels are used. All work is carried out according to the type of work with plaster, only upon completion does not apply sandpaper, since concrete is not subjected to this type of impact.

It will not be difficult to do the installation of natural agglomerate on the surface with your own hands.

For them you will need:

Advice. Special glue is not used when fixing natural stone, as it does not have high strength after drying.

The concrete solution has a gray tint, which is not suitable for every stone design. For this reason, you can add coloring pigment and give it a different color.

The video shows an example of the installation of natural stone in slabs on the surface of the plinth.

Facing stone for the base not only decorates the facade of the house, but also protects against moisture and mechanical damage. The waterproofness of the plinth determines the level of humidity in basement and in living rooms. Artificial stone perfectly imitates natural material due to the relief surface of the outer layer.

Manufactured with flat inner surface, making it easy to install. In this article, we will look at the benefits of cladding. artificial stone and how to do the finishing work with your own hands.

Artificial stone for the plinth has several advantages over its natural counterpart:

Artificial stone for the plinth has several advantages over its natural counterpart:

Fulfill facing works artificial stone, you need to strictly adhere to the laying technology.

The stone is durable and has good thermal insulation qualities.

The stone is durable and has good thermal insulation qualities.

A wide range of artificial stone is available for plinth cladding. Consider what you need to pay attention to when choosing a material:

Before purchasing a material, you need to study its characteristics. Please make sure that the settings match climatic conditions. The solution for grouting must be chosen moisture resistant, resistant to temperature extremes and other atmospheric influences.

From proper preparation surface depends on the overall result when laying the finishing stone on the base. Before performing the cladding, we calculate the permissible load on the foundation.

From proper preparation surface depends on the overall result when laying the finishing stone on the base. Before performing the cladding, we calculate the permissible load on the foundation.

The artificial stone for the plinth is light in weight, but when finishing, the load on the base increases.

Surface preparation steps:

Before laying the artificial facing stone in the lower part of the basement, we mark the horizontal level with a line, while the stone does not need to be leveled along the ground line. If this recommendation is not followed, the entire cladding will be crooked and spoil the appearance of the building.

We prepare tools in advance so that in the process of work we are not distracted by searching for them.

We prepare tools in advance so that in the process of work we are not distracted by searching for them.

Tools:

After the surface and tools are prepared, we proceed to the preparation of the solution.

Cold-resistant mixes for concrete are short-lived

Cold-resistant mixes for concrete are short-lived It is desirable to perform work at a temperature of +5 to +22 degrees.

There are mixtures designed for laying at sub-zero temperatures, but their durability is lower compared to a conventional solution.

When facing in extreme heat, the quality of the mortar decreases due to the fact that cracks form during rapid drying, and the material adheres worse.

Solution preparation:

When using normal river sand sediment will quickly fall off (it is better to use mountain sand). To prevent this, add a handful of building powder to the solution.

The main thing is to connect the elements correctly

The main thing is to connect the elements correctly There are two types of masonry: with and without a seam. If the stone is laid without a seam, then the difficulty lies only in choosing and joining the elements correctly. When working with a seam gasket, you need to choose the material so that an even seam is laid out between it.

Rules for laying stone on the plinth:

The final stage finishing works is a blind area device that protects the plinth from atmospheric influences. It removes moisture away from the foundation, which prolongs the life of the house.

Comparative table of consumption of bricks and large-format stone:

When constructing a blind area, reinforcement is used

When constructing a blind area, reinforcement is used The right device the blind area will protect the foundation from destruction and shrinkage, its width should be 200 mm more than the ledge of the roof.

A blind area is being made with a slope of one and a half degrees or more from the basement to ensure the removal of rainwater and condensate.

Device steps:

As a protection, it is laid longitudinally wooden lath, processed protective compounds protecting from decay. The height of the rail must match the thickness of the concrete. How to make a blind area with your own hands, see this video:

In order for the concrete to form a solid mass during solidification, we cover it with a cloth, which we regularly moisten until the blind area is completely dry. To avoid sudden loss of moisture and cracking, you can cover concrete base polyethylene film.

The basement of the house is exposed to many negative atmospheric and mechanical influences, in this regard, before laying the cladding, it is advisable to insulate it and lay a waterproofing layer.

The basement of the house is exposed to many negative atmospheric and mechanical influences, in this regard, before laying the cladding, it is advisable to insulate it and lay a waterproofing layer.

Exist various materials used for finishing work.

Artificial stone for the plinth is optimal in all respects, it perfectly replaces natural material not only in appearance, but also in strength characteristics.

The basement is the ground part of the foundation of the house. Usually the basement is finished to match the main color of the building so that it does not stand out from general style design. This finish has practical value- it protects the foundation from external influences.

There are several ways to design the foundation - plastering, sheathing with siding or clapboard, facing with natural and artificial stone. Natural stone for finishing the basement is more expensive than other materials and its installation sometimes causes difficulties for inexperienced builders. But thanks to the presentable appearance and organic combination with many styles, it is still popular. Today we will acquaint you with the nuances of this type of finish, as well as the rules for choosing and operating a natural stone coating.

Plinth trimmed with natural stone

The main criterion when choosing a stone is the amount that you are willing to spend on its acquisition. If you want to save money, you should give preference to shell rock, quartzite or sandstone, and if there are no restrictions on funds, attractive and durable granite will do.

These materials for finishing the basement of the foundation are used more often than others:

All varieties of stone differ in the type of surface treatment. This parameter affects the type of material and ease of use. The following surface types are distinguished:

When deciding on the type of treatment, consider whether such material is easy to clean, because the basement of the building is regularly exposed to moisture and dirt. Surfaces with irregularities require more care, especially if we are talking about light shades, on which any streaks immediately become noticeable.

As for the color of the cladding, it is better to take a stone in tone or 2-3 tones darker than the main range of home decoration. And in order for the material to be of high quality and safe for health, be sure to ask the seller to show certificates confirming the origin of the stone.

There should be gaps between the stones

There should be gaps between the stones Plinth finish natural material has a number of features. The main one is the incompatibility of carbonate rocks (shell rock, dolomite, limestone) with silicate rocks (quartzite, sandstone). The ban on their joint use is due to the fact that the substances contained in them are able to interact, which as a result leads to the rapid destruction of both rocks.

remember, that natural materials to finish the basement, the houses are laid with a small gap, since it is common for stones to increase and decrease their volume depending on weather conditions. For each breed, the required gap size is determined individually and depends on its density. If more than one type of stone is used for cladding, a rock with a higher ability to expand is taken as a guide.

Tiles for finishing the basement of a house made of natural stone are an environmentally friendly material, they do not emit harmful fumes, they are durable and reliable. Natural stone has other advantages:

Artificial stone - an affordable alternative

Artificial stone - an affordable alternative Despite the advantages of such a coating, there are also disadvantages - a complex cladding process and high cost. You can simplify the laying of the material by purchasing it not in blocks and cobblestones, but in the form of slabs. And for those who want to save money, the solution will be to finish the basement with artificial stone, which looks almost the same as natural.

To carry out the work, you will need a set of tools, consisting of:

Do-it-yourself plinth finishing begins with surface preparation. If the cladding is carried out over brickwork, then make sure that there are no protruding traces of cement on the inter-brick joints. The concrete base is also inspected for streaks and irregularities and eliminate them.

Stone laying is carried out on a concrete solution. The proportions for its preparation are taken standard and a plasticizer is added to the mixture. This component makes the connection of the plinth surface with the finishing material denser.

Solution preparation

Solution preparation The installation of the material on the wall is carried out in the direction from left to right, starting from the bottom and gradually rising up. If you are working with rubble stone, before laying it, if available heavy pollution It is recommended to wash and then dry thoroughly. Otherwise, it will be difficult to achieve a reliable connection of surfaces.

The sequence of work on finishing the basement of the house with artificial or natural stone:

Stone installation

Stone installation Thus, a mosaic is assembled from suitable stones and cover the entire surface of the base with it. If some pieces do not fit into the overall picture, their size and shape are corrected with a grinder. Places in which voids have formed are filled with small pebbles. Some options for finishing the basement of the house allow laying medium-sized stones of other breeds at the joints, this will enliven and diversify the design. Finally, the seams are cleaned until the solution has had time to completely harden.

Solid houses from a log house are successfully combined with the finishing of the basement with stone, so this design is not uncommon. Facing wooden surface different from brick and concrete. First of all, this concerns preparation work. Before you start laying the material should:

Further, stones or panels for finishing the plinth are laid on an elastic adhesive in the same way as in the case of brick building, and process the seams between them. After facing the entire surface, it is worth additionally protecting the material from moisture. To do this, a layer of stone is coated with a moisture-resistant colorless varnish or hydrophobic impregnation.

Although the stone is a stable material, the plinth lined with it still requires care. It begins with the initial processing after laying. If there are traces of concrete mortar left on the surface, a cement remover will help get rid of them. It is not recommended to use a knife and other sharp objects for this purpose, so as not to scratch the coating.

For further care behind the stone surface, in addition to water, soap for the stone is used. This is a special cleaner that effectively removes dirt, helps to preserve the natural color and forms a thin layer on the surface. protective covering. This composition is recommended to process travertine, granite, marble.

If the plinth was lined with porous materials (shell rock, sandstone), it is useful to cover it with a stone filling agent. It creates a transparent acrylic film over the finish that seals the pores. The material treated in this way becomes resistant to moisture and dirt, is easy to clean and retains its original appearance longer, and the structure of the stone appears more clearly.

Primer treatment will extend the service life

Primer treatment will extend the service life Special funds care is not required for all types of cladding, but their use will benefit the coating. For durable rocks, it is permissible to limit yourself to periodic wiping with a damp cloth, the main thing is not to use aggressive chemicals.

Summing up, we can say that finishing the basement of a house with natural stone with your own hands is a laborious process, but worth it. Attention, accuracy and adherence to the sequence of work will help you cope with this task and get a durable and strong coating that protects the foundation of your home.